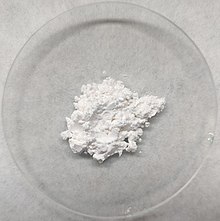

Aluminium oxide(oraluminium(III) oxide) is achemical compoundofaluminiumandoxygenwith thechemical formulaAl2O3.It is the most commonly occurring of severalaluminium oxides,and specifically identified asaluminium oxide.It is commonly calledaluminaand may also be calledaloxide,aloxite,oralundumin various forms and applications. It occurs naturally in its crystallinepolymorphicphaseα-Al2O3as themineralcorundum,varieties of which form the preciousgemstonesrubyandsapphire.Al2O3is used to produce aluminium metal, as anabrasiveowing to itshardness,and as arefractorymaterial owing to its high melting point.[7]

| |

| |

| Names | |

|---|---|

| IUPAC name

Aluminium oxide

| |

| Systematic IUPAC name

Aluminium(III) oxide | |

| Other names

Dialuminium trioxide

| |

| Identifiers | |

3D model (JSmol)

|

|

| ChEMBL | |

| ChemSpider | |

| DrugBank | |

| ECHA InfoCard | 100.014.265 |

| EC Number |

|

PubChemCID

|

|

| RTECS number |

|

| UNII | |

CompTox Dashboard(EPA)

|

|

| |

| |

| Properties | |

| Al2O3 | |

| Molar mass | 101.960g·mol−1 |

| Appearance | white solid |

| Odor | odorless |

| Density | 3.987 g/cm3 |

| Melting point | 2,072 °C (3,762 °F; 2,345 K)[3] |

| Boiling point | 2,977 °C (5,391 °F; 3,250 K)[4] |

| insoluble | |

| Solubility | insoluble in all solvents |

| logP | 0.31860[1] |

| −37.0×10−6cm3/mol | |

| Thermal conductivity | 30 W·m−1·K−1[2] |

Refractive index(nD)

|

nω= 1.768–1.772 nε= 1.760–1.763 Birefringence0.008 |

| Structure | |

| Trigonal,hR30 | |

| R3c (No. 167) | |

a= 478.5 pm,c= 1299.1 pm

| |

| octahedral | |

| Thermochemistry | |

Std molar

entropy(S⦵298) |

50.92 J·mol−1·K−1[5] |

Std enthalpy of

formation(ΔfH⦵298) |

−1675.7 kJ/mol[5] |

| Pharmacology | |

| D10AX04(WHO) | |

| Hazards | |

| GHSlabelling: | |

| |

| NFPA 704(fire diamond) | |

| Flash point | Non-flammable |

| NIOSH(US health exposure limits): | |

PEL(Permissible)

|

OSHA 15 mg/m3(total dust) OSHA 5 mg/m3(respirable fraction) ACGIH/TLV 10 mg/m3 |

REL(Recommended)

|

none[6] |

IDLH(Immediate danger)

|

N.D.[6] |

| Related compounds | |

Otheranions

|

aluminium hydroxide aluminium sulfide aluminium selenide |

Othercations

|

boron trioxide gallium(III) oxide indium oxide thallium(III) oxide |

| Supplementary data page | |

| Aluminium oxide (data page) | |

Except where otherwise noted, data are given for materials in theirstandard state(at 25 °C [77 °F], 100 kPa).

| |

Natural occurrence

editCorundumis the most common naturally occurringcrystallineform of aluminium oxide.[8]Rubiesandsapphiresare gem-quality forms of corundum, which owe their characteristic colours to trace impurities. Rubies are given their characteristic deep red colour and theirlaserqualities by traces ofchromium.Sapphires come in different colours given by various other impurities, such as iron and titanium. An extremely rare δ form occurs as the mineral deltalumite.[9][10]

History

editThe field of aluminium oxide ceramics has a long history. Aluminium salts were widely used in ancient and medievalalchemy.Several older textbooks cover the history of the field.[11][12]A 2019 textbook by Andrew Ruys contains a detailed timeline on the history of aluminium oxide from ancient times to the 21st century.[13]

Properties

editAl2O3is anelectrical insulatorbut has a relatively highthermal conductivity(30 Wm−1K−1)[2]for a ceramic material. Aluminium oxide is insoluble in water. In its most commonly occurring crystalline form, calledcorundumor α-aluminium oxide, its hardness makes it suitable for use as anabrasiveand as a component incutting tools.[7]

Aluminium oxide is responsible for the resistance of metallic aluminium toweathering.Metallic aluminium is very reactive with atmospheric oxygen, and a thinpassivation layerof aluminium oxide (4 nm thickness) forms on any exposed aluminium surface in a matter of hundreds of picoseconds.[better source needed][14]This layer protects the metal from further oxidation. The thickness and properties of this oxide layer can be enhanced using a process calledanodising.A number ofalloys,such asaluminium bronzes,exploit this property by including a proportion of aluminium in the alloy to enhance corrosion resistance. The aluminium oxide generated by anodising is typicallyamorphous,but discharge-assisted oxidation processes such asplasma electrolytic oxidationresult in a significant proportion of crystalline aluminium oxide in the coating, enhancing itshardness.

Aluminium oxide was taken off theUnited States Environmental Protection Agency's chemicals lists in 1988. Aluminium oxide is on the EPA'sToxics Release Inventorylist if it is a fibrous form.[15]

Amphoteric nature

editAluminium oxide is anamphotericsubstance, meaning it can react with bothacidsandbases,such ashydrofluoric acidandsodium hydroxide,acting as an acid with a base and a base with an acid, neutralising the other and producing a salt.

- Al2O3+ 6 HF → 2AlF3+ 3 H2O

- Al2O3+ 2 NaOH + 3 H2O → 2 NaAl(OH)4(sodium aluminate)

Structure

editThe most common form of crystalline aluminium oxide is known ascorundum,which is the thermodynamically stable form.[16]The oxygen ions form a nearlyhexagonal close-packedstructure with the aluminium ions filling two-thirds of the octahedral interstices. Each Al3+center isoctahedral.In terms of itscrystallography,corundum adopts atrigonalBravais latticewith aspace groupofR3c(number 167 in the International Tables). Theprimitive cellcontains two formula units of aluminium oxide.

Aluminium oxide also exists in other metastable phases, including the cubic γ and η phases, the monoclinic θ phase, the hexagonal χ phase, the orthorhombic κ phase and the δ phase that can be tetragonal or orthorhombic.[16][17]Each has a unique crystal structure and properties. Cubic γ-Al2O3has important technical applications. The so-called β-Al2O3proved to be NaAl11O17.[18]

Molten aluminium oxide near the melting temperature is roughly 2/3tetrahedral(i.e. 2/3 of the Al are surrounded by 4 oxygen neighbors), and 1/3 5-coordinated, with very little (<5%)octahedralAl-O present.[19]Around 80% of the oxygen atoms are shared among three or more Al-O polyhedra, and the majority of inter-polyhedral connections are corner-sharing, with the remaining 10–20% being edge-sharing.[19]The breakdown of octahedra upon melting is accompanied by a relatively large volume increase (~33%), the density of the liquid close to its melting point is 2.93 g/cm3.[20]The structure of molten alumina is temperature dependent and the fraction of 5- and 6-fold aluminium increases during cooling (and supercooling), at the expense of tetrahedral AlO4units, approaching the local structural arrangements found in amorphous alumina.[21]

Production

editAluminiumhydroxideminerals are the main component ofbauxite,the principaloreofaluminium.A mixture of the minerals comprise bauxite ore, includinggibbsite(Al(OH)3),boehmite(γ-AlO(OH)), anddiaspore(α-AlO(OH)), along with impurities ofiron oxidesand hydroxides, quartz andclay minerals.[22]Bauxites are found inlaterites.Bauxite is typically purified using theBayer process:

- Al2O3+ H2O + NaOH → NaAl(OH)4

- Al(OH)3+ NaOH → NaAl(OH)4

Except for SiO2,the other components of bauxite do not dissolve in base. Upon filtering the basic mixture, Fe2O3is removed. When the Bayer liquor is cooled, Al(OH)3precipitates, leaving the silicates in solution.

- NaAl(OH)4→ NaOH + Al(OH)3

The solid Al(OH)3Gibbsiteis thencalcined(heated to over 1100 °C) to give aluminium oxide:[7]

- 2 Al(OH)3→ Al2O3+ 3 H2O

The product aluminium oxide tends to be multi-phase, i.e., consisting of several phases of aluminium oxide rather than solelycorundum.[17]The production process can therefore be optimized to produce a tailored product. The type of phases present affects, for example, the solubility and pore structure of the aluminium oxide product which, in turn, affects the cost of aluminium production and pollution control.[17]

Sintering Process

editThe Sintering Process is a high-temperature method primarily used when the Bayer Process is not suitable, especially fororeswith highsilicacontent or when a more controlled product morphology is required.[23]Firstly,Bauxiteis mixed with additives likelimestoneand soda ash, then heating the mixture at high temperatures (1200 °C to 1500 °C) to formsodium aluminateandcalcium silicate.[24]After sintering, the material is leached with water to dissolve thesodium aluminate,leaving behind impurities. Sodium aluminate is then precipitated from the solution and calcined at around 1000 °C to produce alumina.[25]This method is useful for the production of complex shapes and can be used to create porous or dense materials.[26]

Applications

editKnown asalpha aluminainmaterials science,and asalundum(in fused form) oraloxite[27]inminingandceramiccommunities, aluminium oxide finds wide use. Annual global production of aluminium oxide in 2015 was approximately 115 milliontonnes,over 90% of which was used in the manufacture of aluminium metal.[7]The major uses of speciality aluminium oxides are in refractories, ceramics, polishing and abrasive applications. Large tonnages of aluminium hydroxide, from which alumina is derived, are used in the manufacture ofzeolites,coatingtitaniapigments, and as a fire retardant/smoke suppressant.

Over 90% of aluminium oxide, termedsmelter grade alumina(SGA), is consumed for the production of aluminium, usually by theHall–Héroult process.The remainder, termedspecialty alumina,is used in a wide variety of applications which take advantage of its inertness, temperature resistance and electrical resistance.[28]

Fillers

editBeing fairly chemically inert and white, aluminium oxide is a favored filler for plastics. Aluminium oxide is a common ingredient insunscreen[29]and is often also present in cosmetics such as blush, lipstick, and nail polish.[30]

Glass

editMany formulations ofglasshave aluminium oxide as an ingredient.[31]Aluminosilicate glass is a commonly used type of glass that often contains 5% to 10% alumina.

Catalysis

editAluminium oxide catalyses a variety of reactions that are useful industrially. In its largest scale application, aluminium oxide is the catalyst in theClaus processfor converting hydrogen sulfide waste gases into elemental sulfur in refineries. It is also useful fordehydrationofalcoholstoalkenes.

Aluminium oxide serves as acatalyst supportfor many industrial catalysts, such as those used inhydrodesulfurizationand someZiegler–Nattapolymerizations.

Gas purification

editAluminium oxide is widely used to remove water from gas streams.[32]

Abrasion

editAluminium oxide is used for its hardness and strength. Its naturally occurring form,corundum,is a 9 on theMohs scale of mineral hardness(just below diamond). It is widely used as anabrasive,including as a much less expensive substitute forindustrial diamond.Many types ofsandpaperuse aluminium oxide crystals. In addition, its low heat retention and lowspecific heatmake it widely used in grinding operations, particularlycutofftools. As the powdery abrasive mineralaloxite,it is a major component, along withsilica,of thecue tip"chalk" used inbilliards.Aluminium oxide powder is used in someCD/DVDpolishingand scratch-repair kits. Its polishing qualities are also behind its use in toothpaste. It is also used inmicrodermabrasion,both in the machine process available through dermatologists and estheticians, and as a manual dermal abrasive used according to manufacturer directions.

Paint

editAluminium oxide flakes are used in paint for reflective decorative effects, such as in the automotive or cosmetic industries.[citation needed]

Biomedical Applications

editAluminium oxide is a representative of bioinert ceramics.[33]Due to its excellent biocompatibility, high strength, and wear resistance, alumina ceramics are used in medical applications to manufacture artificial bones and joints.[34]It is also used for manufacturing dental implants, joint replacements, and other medical devices.[35]

Composite fiber

editAluminium oxide has been used in a few experimental and commercial fiber materials for high-performance applications (e.g., Fiber FP, Nextel 610, Nextel 720).[36]Aluminananofibersin particular have become a research field of interest.

Armor

editSome body armors utilize alumina ceramic plates, usually in combination with aramid or UHMWPE backing to achieve effectiveness against most rifle threats. Alumina ceramic armor is readily available to most civilians in jurisdictions where it is legal, but is not considered military grade.[37]It is also used to produce bullet-proof alumina glass capable to withstand impact of.50 BMGcalibre rounds.

Abrasion protection

editAluminium oxide can be grown as a coating on aluminium byanodizingor byplasma electrolytic oxidation(see the "Properties" above). Both thehardnessand abrasion-resistant characteristics of the coating originate from the high strength of aluminium oxide, yet the porous coating layer produced with conventional direct current anodizing procedures is within a 60–70 Rockwell hardness C range[38]which is comparable only to hardened carbon steel alloys, but considerably inferior to the hardness of natural and synthetic corundum. Instead, withplasma electrolytic oxidation,the coating is porous only on the surface oxide layer while the lower oxide layers are much more compact than with standard DC anodizing procedures and present a higher crystallinity due to the oxide layers being remelted and densified to obtain α-Al2O3 clusters with much higher coating hardness values circa 2000 Vickers hardness.[citation needed]

Alumina is used to manufacture tiles which are attached inside pulverized fuel lines and flue gas ducting on coal fired power stations to protect high wear areas. They are not suitable for areas with high impact forces as these tiles are brittle and susceptible to breakage.

Electrical insulation

editAluminium oxide is an electricalinsulatorused as a substrate (silicon on sapphire) forintegrated circuitsbut also as atunnel barrierfor the fabrication ofsuperconductingdevices such assingle-electron transistors,superconducting quantum interference devices (SQUIDs) andsuperconducting qubits.

For its application as an electrical insulator in integrated circuits, where the conformal growth of a thin film is a prerequisite and the preferred growth mode isatomic layer deposition,Al2O3films can be prepared by the chemical exchange betweentrimethylaluminium(Al(CH3)3) and H2O:[39]

- 2 Al(CH3)3+ 3 H2O → Al2O3+ 6 CH4

H2O in the above reaction can be replaced byozone(O3) as the active oxidant and the following reaction then takes place:[40][41]

- 2 Al(CH3)3+ O3→ Al2O3+ 3 C2H6

The Al2O3films prepared using O3show 10–100 times lower leakage current density compared with those prepared by H2O.

Aluminium oxide, being a dielectric with relatively largeband gap,is used as an insulating barrier incapacitors.[42]

Other

editIn lighting, translucent aluminium oxide is used in somesodium vapor lamps.[43]Aluminium oxide is also used in preparation of coating suspensions incompact fluorescent lamps.

In chemistry laboratories, aluminium oxide is a medium forchromatography,available inbasic(pH 9.5),acidic(pH 4.5 when in water) and neutral formulations. Additionally, small pieces of aluminium oxide are often used asboiling chips.

Health and medical applications include it as a material inhip replacements[7]andbirth control pills.[44]

It is used as ascintillator[45] anddosimeterfor radiation protection and therapy applications for itsoptically stimulated luminescenceproperties.[citation needed]

Insulation for high-temperature furnaces is often manufactured from aluminium oxide. Sometimes the insulation has varying percentages of silica depending on the temperature rating of the material. The insulation can be made in blanket, board, brick and loose fiber forms for various application requirements.

It is also used to makespark pluginsulators.[46]

Using aplasma sprayprocess and mixed withtitania,it is coated onto the braking surface of somebicyclerims to provide abrasion and wear resistance.[citation needed]

Most ceramic eyes on fishing rods are circular rings made from aluminium oxide.[citation needed]

In its finest powdered (white) form, called Diamantine, aluminium oxide is used as a superior polishing abrasive in watchmaking and clockmaking.[47]

Aluminium oxide is also used in the coating of stanchions in the motorcross and mountainbike industry. This coating is combined with molybdenumdisulfate to provide long term lubrication of the surface.[48]

See also

editReferences

edit- ^"Aluminum oxide_msds".

- ^abMaterial Properties Data: Alumina (Aluminum Oxide)Archived2010-04-01 at theWayback Machine.Makeitfrom.com. Retrieved on 2013-04-17.

- ^Patnaik, P. (2002).Handbook of Inorganic Chemicals.McGraw-Hill.ISBN978-0-07-049439-8.

- ^Raymond C. Rowe; Paul J. Sheskey; Marian E. Quinn (2009). "Adipic acid".Handbook of Pharmaceutical Excipients.Pharmaceutical Press. pp. 11–12.ISBN978-0-85369-792-3.

- ^abZumdahl, Steven S. (2009).Chemical Principles 6th Ed.Houghton Mifflin Company.ISBN978-0-618-94690-7.

- ^abNIOSH Pocket Guide to Chemical Hazards."#0021".National Institute for Occupational Safety and Health(NIOSH).

- ^abcde"Alumina (Aluminium Oxide) – The Different Types of Commercially Available Grades".The A to Z of Materials. 3 May 2002. Archived fromthe originalon 10 October 2007.Retrieved27 October2007.

- ^Elam, J. W. (October 2010).Atomic Layer Deposition Applications 6.The Electrochemical Society.ISBN9781566778213.

- ^"Deltalumite".

- ^"List of Minerals".21 March 2011.

- ^Gitzen, Walter (1970).Alumina as a Ceramic Material.Wiley.

- ^Dorre, Erhard; Hubner, Heinz (1984).Alumina, Processing, Properties, and Applications.Berlin; New York: Springer-Verlag. p. 344.

- ^Ruys, Andrew J. (2019).Alumina Ceramics: Biomedical and Industrial Applications.Duxford, UK: Elsevier. p. 558.ISBN978-0-08-102442-3.

- ^Campbell, Timothy; Kalia, Rajiv; Nakano, Aiichiro; Vashishta, Priya; Ogata, Shuji; Rodgers, Stephen (1999)."Dynamics of Oxidation of Aluminium Nanoclusters using Variable Charge Molecular-Dynamics Simulations on Parallel Computers"(PDF).Physical Review Letters.82(24): 4866.Bibcode:1999PhRvL..82.4866C.doi:10.1103/PhysRevLett.82.4866.Archived(PDF)from the original on 2010-07-01.

- ^"EPCRA Section 313 Chemical List For Reporting Year 2006"(PDF).US EPA. Archived fromthe original(PDF)on 2008-05-22.Retrieved2008-09-30.

- ^abI. Levin; D. Brandon (1999). "Metastable Alumina Polymorphs: Crystal Structures and Transition Sequences".Journal of the American Ceramic Society.81(8): 1995–2012.doi:10.1111/j.1151-2916.1998.tb02581.x.

- ^abcPaglia, G. (2004)."Determination of the Structure of γ-Alumina using Empirical and First Principles Calculations Combined with Supporting Experiments"(free download).Curtin University of Technology, Perth.Retrieved2009-05-05.

- ^Wiberg, E.; Holleman, A. F. (2001).Inorganic Chemistry.Elsevier.ISBN978-0-12-352651-9.

- ^abSkinner, L.B.; et al. (2013)."Joint diffraction and modeling approach to the structure of liquid alumina".Phys. Rev. B.87(2): 024201.Bibcode:2013PhRvB..87b4201S.doi:10.1103/PhysRevB.87.024201.

- ^Paradis, P.-F.; et al. (2004). "Non-Contact Thermophysical Property Measurements of Liquid and Undercooled Alumina".Jpn. J. Appl. Phys.43(4): 1496–1500.Bibcode:2004JaJAP..43.1496P.doi:10.1143/JJAP.43.1496.S2CID250779901.

- ^Shi, C; Alderman, O L G; Berman, D; Du, J; Neuefeind, J; Tamalonis, A; Weber, R; You, J; Benmore, C J (2019)."The structure of amorphous and deeply supercooled liquid alumina".Frontiers in Materials.6(38): 38.Bibcode:2019FrMat...6...38S.doi:10.3389/fmats.2019.00038.

- ^"Bauxite and Alumina Statistics and Information".USGS.Archivedfrom the original on 6 May 2009.Retrieved2009-05-05.

- ^Alton T. Tabereaux, Ray D. Peterson (2014). "Chapter 2.5 - Aluminum Production". In Seshadri Seetharaman (ed.).Treatise on Process Metallurgy.Elsevier. pp. 839–917.ISBN9780080969886.

- ^Bordboland, Reza; Azizi, Asghar; Khani, Mohammad (2024). "Extracting Alumina from a Low-grade (Shale) Bauxite Ore using a Sintering Process with Lime-soda followed by Alkali Leaching".Journal of Mining and Environment.15(3): 1131–1148.doi:10.22044/jme.2024.13905.2588.

- ^Sun, Yue; Pan, Aifang (2023). "Extraction of alumina and silica from high-silica bauxite by sintering with sodium carbonate followed by two-step leaching with water and sulfuric acid".RSC Advances.13:23254–23266.

- ^"Several Production Methods of Alumina and Their Advantages".Precise Ceramics.Apr 3, 2024.RetrievedAug 19,2024.

- ^"Aloxite".ChemIndustry.com database.Archivedfrom the original on 25 June 2007.Retrieved24 February2007.

- ^Evans, K. A. (1993). "Properties and uses of aluminium oxides and aluminium hydroxides". In Downs, A. J. (ed.).The Chemistry of Aluminium, Indium and Gallium.Blackie Academic.ISBN978-0751401035.

- ^"Alumina".INCI Decoder.Archived fromthe originalon 5 February 2023.Retrieved20 June2023.

- ^"Alumina (Ingredient Explained + Products)".SkinSort.Archived fromthe originalon 15 October 2023.Retrieved15 October2023.

- ^Akers, Michael J. (2016-04-19).Sterile Drug Products: Formulation, Packaging, Manufacturing and Quality.CRC Press.ISBN9781420020564.

- ^Hudson, L. Keith; Misra, Chanakya; Perrotta, Anthony J.; Wefers, Karl and Williams, F. S. (2002) "Aluminum Oxide" inUllmann's Encyclopedia of Industrial Chemistry,Wiley-VCH, Weinheim.doi:10.1002/14356007.a01_557.

- ^Ishikawa, K.; Matsuya, S. (2003).Comprehensive Structural Integrity.Vol. 9. Elsevier Science. pp. 169–214.ISBN978-0-08-043749-1.RetrievedMay 27,2024.

- ^"Alumina (Al2O3), Aluminum Oxide".Precise Ceramic.RetrievedMay 27,2024.

- ^"Metals and Minerals in Medical Implants".USGS.RetrievedMay 27,2024.

- ^Mallick, P.K. (2008).Fiber-reinforced composites materials, manufacturing, and design(3rd ed., [expanded and rev. ed.] ed.). Boca Raton, FL: CRC Press. pp. Ch.2.1.7.ISBN978-0-8493-4205-9.

- ^"Ballistic Resistance of Body Armor"(PDF).US Department of Justice.NIJ.Retrieved31 August2018.

- ^Osborn, Joseph H. (2014)."understanding and specifying anodizing: what a manufacturer needs to know".OMW Corporation.Archived fromthe originalon 2016-11-20.Retrieved2018-06-02.

- ^Higashi GS, Fleming (1989). "Sequential surface chemical reaction limited growth of high quality Al2O3dielectrics ".Appl. Phys. Lett.55(19): 1963–65.Bibcode:1989ApPhL..55.1963H.doi:10.1063/1.102337.

- ^Kim JB; Kwon DR; Chakrabarti K; Lee Chongmu; Oh KY; Lee JH (2002). "Improvement in Al2O3dielectric behavior by using ozone as an oxidant for the atomic layer deposition technique ".J. Appl. Phys.92(11): 6739–42.Bibcode:2002JAP....92.6739K.doi:10.1063/1.1515951.

- ^Kim, Jaebum; Chakrabarti, Kuntal; Lee, Jinho; Oh, Ki-Young; Lee, Chongmu (2003). "Effects of ozone as an oxygen source on the properties of the Al2O3thin films prepared by atomic layer deposition ".Mater Chem Phys.78(3): 733–38.doi:10.1016/S0254-0584(02)00375-9.

- ^Belkin, A.; Bezryadin, A.; Hendren, L.; Hubler, A. (20 April 2017)."Recovery of Alumina Nanocapacitors after High Voltage Breakdown".Scientific Reports.7(1): 932.Bibcode:2017NatSR...7..932B.doi:10.1038/s41598-017-01007-9.PMC5430567.PMID28428625.

- ^"GE Innovation Timeline 1957–1970".Archivedfrom the original on 16 February 2009.Retrieved2009-01-12.

- ^"DailyMed - JUNEL FE 1/20- norethindrone acetate and ethinyl estradiol, and ferrous fumarate".dailymed.nlm.nih.gov.Archivedfrom the original on 2017-03-13.Retrieved2017-03-13.

- ^V.B. Mikhailik, H. Kraus (2005). "Low-temperature spectroscopic and scintillation characterisation of Ti-doped Al2O3".Nucl. Instr. Phys. Res. A.546(3): 523–534.Bibcode:2005NIMPA.546..523M.doi:10.1016/j.nima.2005.02.033.

- ^Farndon, John (2001).Aluminium.Marshall Cavendish. p.19.ISBN9780761409472.

Aluminium oxide is also used to make spark plug insulators.

- ^de Carle, Donald (1969).Practical Watch Repair.N.A.G. Press Ltd. p. 164.ISBN0719800307.

- ^"Kashima Coat - Products / Services | Next-generation anodize boasting light weight, high lubrication, and superb wear resistance. The answer is Miyaki's Kashima Coat".

External links

edit