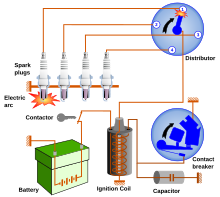

Adistributoris an electric and mechanical device used in theignition systemof olderspark ignition engines.The distributor's main function is to route electricity from theignition coilto eachspark plugat the correct time.

Design

editThis sectionneeds additional citations forverification.(January 2023) |

A distributor consists of a rotating arm ('rotor') that is attached to the top of a rotating 'distributor shaft'. The rotor constantly receives high-voltage electricity from anignition coilviabrushesat the centre of the rotor. As the rotor spins, its tip passes close to (but does not touch) the output contacts for eachcylinder.As the electrified tip passes each output contact, the high-voltage electricity is able to 'jump' across the small gap.[1]This burst of electricity then travels to thespark plug(viahigh tension leads), where it ignites the air-fuel mixture in the combustion chamber.

On mostoverhead valve engines,the distributor shaft is driven by a gear on thecamshaft,often shared with theoil pump;on mostoverhead camshaft engines,the distributor shaft is attached directly to a camshaft.

Older distributor designs used acamon the distributor shaft that operates thecontact breaker(also calledpoints). Opening the points causes a highinductionvoltage in the ignition coil.[1]This design was superseded by an electronically controlled ignition coil with a sensor (usuallyHall effector optical) to control the timing of the ignition coil charging.

Ignition advance

editIn older distributors, adjusting theignition timingis usually achieved through bothmechanical advanceandvacuum advance.Mechanical advanceadjusts the timing based on the engine speed (rpm), using a set of hinged weights attached to the distributor shaft. These weights cause the breaker points mounting plate to slightly rotate, thereby advancing the ignition timing.Vacuum advancetypically usesmanifold vacuumto adjust the ignition timing, for example to improve fuel economy and driveability when minimal power is required from the engine.

Most distributors used onelectronic fuel injectionengines use electronics to adjust the ignition timing, instead of vacuum and centrifugal systems. This allows the ignition timing to be optimised based on factors other than engine speed and manifold vacuum.

Direct ignition

editSince the early 2000s, many cars have used a 'coil-on-plug'direct ignitionsystem, whereby a small ignition coil is located directly above the spark plug for each cylinder. This design means that high-voltage electricity is only present in the small distance between each coil and the spark plug. SeeSaab Direct Ignition.

Gallery

edit-

Breaker arm with contact points at the left. The pivot is on the right and the cam follower is in the middle of the breaker arm.

-

Distributor cap. At the center is a spring-loaded carbon button that touches the rotor. The number of contacts (in this case 4) is the same as the number ofengine cylinders.

-

Rotor. This rotates at the same speed as the camshaft, one half the speed of thecrankshaft.

-

Top of distributor withwiresand terminals

-

Rotor contacts inside distributor cap

History

editThe first mass-produced electric ignition was theDelco ignition system,which was introduced in the 1910Cadillac Model 30.In 1921,Arthur Atwater Kent Srinvented the competingUnisparkerignition system.[2]

By the 1980s and 1990s, distributors had been largely replaced byelectronic ignitionsystems.

See also

editReferences

edit- ^ab"How the ignition system works".How a Car Works.Retrieved2016-02-12.

- ^"Cadillac History | Kanter Car Tales".kanter-car-tales.com.Archived fromthe originalon 2016-03-05.Retrieved2016-02-12.