Silkis anaturalproteinfiber,some forms of which can bewovenintotextiles.The protein fiber of silk is composed mainly offibroinand is produced by certain insectlarvaeto formcocoons.[1]The best-known silk is obtained from the cocoons of the larvae of themulberry silkwormBombyx morireared in captivity (sericulture). The shimmering appearance of silk is due to the triangularprism-like structure of the silk fibre, which allows silk cloth to refract incoming light at differentangles,thus producing different colors.

| Silk | |

|---|---|

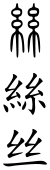

"Silk" inseal script(top), Traditional (middle), and Simplified (bottom) Chinese | |

| Chinese name | |

| Traditional Chinese | Ti |

| Simplified Chinese | Ti |

| Vietnamese name | |

| Vietnamese alphabet | lụa |

| Chữ Nôm | Lũ |

| Japanese name | |

| Kanji | Quyên |

| Kana | きぬ |

Bombyx mori,Hyalophora cecropia,Antheraea pernyi,Samia cynthia.

FromMeyers Konversations-Lexikon(1885–1892)

Silk is produced by several insects; but, generally, only the silk of moth caterpillars has been used for textile manufacturing. There has been some research into other types of silk, which differ at the molecular level.[2]Silk is mainly produced by the larvae of insects undergoingcomplete metamorphosis,but some insects, such aswebspinnersandraspy crickets,produce silk throughout their lives.[3]Silk production also occurs inhymenoptera(bees,wasps,andants),silverfish,caddisflies,mayflies,thrips,leafhoppers,beetles,lacewings,fleas,flies,andmidges.[2]Other types ofarthropodsproduce silk, most notably variousarachnids,such asspiders.

Etymology

The word silk comes fromOld English:sioloc,fromLatin:sericum[4]andAncient Greek:σηρικός,romanized:sērikós,"silken", ultimately from the Chinese word "sī" and other Asian sources—compareMandarinsī"silk",Manchuriansirghe,Mongoliansirkek.[5]

History

The production of silk originated inChinain theNeolithicperiod, although it would eventually reach other places of the world (Yangshaoculture, 4th millennium BC). Silk production remained confined to China until theSilk Roadopened at some point during the latter part of the 1st millennium BC, though China maintained its virtualmonopolyoversilk productionfor another thousand years.

Wild silk

Several kinds of wild silk, produced bycaterpillarsother than themulberrysilkworm, have been known and spun inChina,South Asia,andEuropesince ancient times. However, the scale of production was always far smaller than for cultivated silks. There are several reasons for this: first, they differ from the domesticated varieties in colour andtextureand are therefore less uniform; second, cocoons gathered in the wild have usually had the pupa emerge from them before being discovered so the silk thread that makes up the cocoon has been torn into shorter lengths; and third, many wild cocoons are covered in a mineral layer that prevents attempts to reel from them long strands of silk.[6]Thus, the only way to obtain silk suitable for spinning into textiles in areas where commercial silks are not cultivated was by tedious and labor-intensivecarding.

Some natural silk structures have been used without being unwound or spun. Spider webs were used as a wound dressing in ancient Greece and Rome,[7]and as a base forpaintingfrom the 16th century.[8]Caterpillar nests were pasted together to make a fabric in theAztec Empire.[9]

Commercial silks originate from reared silkworm pupae, which are bred to produce a white-colored silk thread with no mineral on the surface. The pupae are killed by either dipping them in boiling water before the adult moths emerge or by piercing them with a needle. These factors all contribute to the ability of the whole cocoon to be unravelled as one continuous thread, permitting a much stronger cloth to be woven from the silk. Wild silks also tend to be more difficult to dye than silk from the cultivated silkworm.[10][11]A technique known asdemineralizingallows the mineral layer around the cocoon of wild silk moths to be removed,[12]leaving only variability in color as a barrier to creating a commercial silk industry based on wild silks in the parts of the world where wild silk moths thrive, such as in Africa and South America.

China

Silk use in fabric was first developed in ancient China.[13][14]The earliest evidence for silk is the presence of the silk proteinfibroinin soil samples from two tombs at theneolithicsiteJiahuinHenan,which date back about 8,500 years.[15][16]The earliest surviving example of silk fabric dates from about 3630 BC, and was used as the wrapping for the body of a child at aYangshao culturesite in Qingtaicun nearXingyang,Henan.[13][17]

Legend gives credit for developing silk to a Chinese empress,Leizu(Hsi-Ling-Shih, Lei-Tzu). Silks were originally reserved for the emperors of China for their own use and gifts to others, but spread gradually throughChinese cultureand trade both geographically and socially, and then to many regions ofAsia.Because of its texture and lustre, silk rapidly became a popular luxury fabric in the many areas accessible to Chinese merchants. Silk was in great demand, and became a staple of pre-industrialinternationaltrade.Silk was also used as a surface for writing, especially during the Warring States period (475–221 BCE). The fabric was light, it survived the damp climate of the Yangtze region, absorbed ink well, and provided a white background for the text.[18]In July 2007, archaeologists discovered intricately woven and dyed silktextilesin a tomb inJiangxiprovince, dated to the EasternZhou dynastyroughly 2,500 years ago.[19]Although historians have suspected a long history of a formative textile industry in ancient China, this find of silk textiles employing "complicated techniques" of weaving and dyeing provides direct evidence for silks dating before theMawangdui-discovery and other silks dating to theHan dynasty(202 BC – 220 AD).[19]

Silk is described in a chapter of theFan Shengzhi shufrom the Western Han (202 BC – 9 AD). There is a surviving calendar for silk production in an Eastern Han (25–220 AD) document. The two other known works on silk from the Han period are lost.[13]The first evidence of the long distance silk trade is the finding of silk in the hair of anEgyptianmummyof the 21st dynasty, c.1070 BC.[20]The silk trade reached as far as theIndian subcontinent,theMiddle East,Europe,andNorth Africa.This trade was so extensive that the major set of trade routes between Europe and Asia came to be known as theSilk Road.

Theemperors of Chinastrove to keep knowledge ofsericulturesecret to maintain the Chinesemonopoly.Nonetheless, sericulture reachedKoreawith technological aid from China around 200 BC,[21]the ancientKingdom of Khotanby AD 50,[22]andIndiaby AD 140.[23]

In the ancient era, silk from China was the most lucrative and sought-after luxury item traded across the Eurasian continent,[24]and many civilizations, such as the ancient Persians, benefited economically from trade.[24]

- Chinese silk making process

-

The silkworms and mulberry leaves are placed on trays.

-

Twig frames for the silkworms are prepared.

-

The cocoons are weighed.

-

The cocoons are soaked and the silk is wound on spools.

-

The silk is woven using a loom.

Japan

Archaeological evidence indicates thatsericulturehas been practiced since theYayoi period.The silk industry was dominant from the 1930s to 1950s, but is less common now.[25] Silk fromEast Asiahad declined in importance aftersilkworms were smuggledfromChinato theByzantineEmpire. However, in 1845, an epidemic offlacherieamong European silkworms devastated the silk industry there.[26]This led to a demand for silk fromChinaandJapan,where as late as the nineteenth and early twentieth centuries, Japanese exports competed directly with Chinese in the international market in such low value-added, labor-intensive products as raw silk.

Between 1850 and 1930, raw silk ranked as the leading export for both countries, accounting for 20%–40% of Japan's total exports and 20%–30% of China's.[27]Between the 1890s and the 1930s, Japanese silk exports quadrupled, making Japan the largest silk exporter in the world. This increase in exports was mostly due to the economic reforms during theMeiji periodand the decline of theQingdynasty in China, which led to rapid industrialization of Japan whilst the Chinese industries stagnated.[27]

DuringWorld War II,embargoes against Japan had led to adoption of synthetic materials such asnylon,[28]which led to the decline of the Japanese silk industry and its position as the lead silk exporter of the world. Today, China exports the largest volume of raw silk in the world.[29]

India

Silk has a long history in India. It is known asReshamin eastern and north India, andPattuin southern parts ofIndia.Recent archaeological discoveries inHarappaandChanhu-darosuggest thatsericulture,employingwild silkthreads from nativesilkwormspecies, existed inSouth Asiaduring the time of theIndus Valley civilisation(now inPakistanand India) dating between 2450 BC and 2000 BC.[30][31]Shelagh Vainker, a silk expert at theAshmolean Museumin Oxford, who sees evidence for silk production in China "significantly earlier" than 2500–2000 BC, suggests, "people of the Indus civilization either harvested silkworm cocoons or traded with people who did, and that they knew a considerable amount about silk."[30]

India is the second largest producer of silk in the world after China. About 97% of the raw mulberry silk comes from six Indian states, namely,Andhra Pradesh,Karnataka,Jammu and Kashmir,Tamil Nadu,Bihar,andWest Bengal.[32]North Bangalore, the upcoming site of a $20 million "Silk City"RamanagaraandMysore,contribute to a majority of silk production in Karnataka.[33]

InTamil Nadu,mulberry cultivation is concentrated in theCoimbatore,Erode,Bhagalpuri,Tiruppur,Salem,andDharmapuridistricts.Hyderabad,Andhra Pradesh,andGobichettipalayam,Tamil Nadu,were the first locations to have automated silk reeling units in India.[34]

In the northeastern state ofAssam,three different types of indigenous variety of silk are produced, collectively calledAssam silk:Muga silk,Eri silkandPat silk.Muga, the golden silk, and Eri are produced by silkworms that are native only to Assam. They have been reared since ancient times similar to other East and South-East Asian countries.[citation needed]

Thailand

Silk is produced year-round in Thailand by two types of silkworms, the cultured Bombycidae and wild Saturniidae. Most production is after the rice harvest in the southern and northeastern parts of the country. Women traditionally weave silk on hand looms and pass the skill on to their daughters, as weaving is considered to be a sign of maturity and eligibility for marriage. Thai silk textiles often use complicated patterns in various colours and styles. Most regions of Thailand have their own typical silks. A single threadfilamentis too thin to use on its own so women combine many threads to produce a thicker, usable fiber. They do this by hand-reeling the threads onto a wooden spindle to produce a uniform strand of raw silk. The process takes around 40 hours to produce a half kilogram of silk. Many local operations use a reeling machine for this task, but some silk threads are still hand-reeled. The difference is that hand-reeled threads produce three grades of silk: two fine grades that are ideal for lightweight fabrics, and a thick grade for heavier material.

The silk fabric is soaked in extremely cold water and bleached before dyeing to remove the natural yellow coloring of Thai silk yarn. To do this, skeins of silk thread are immersed in large tubs ofhydrogen peroxide.Once washed and dried, the silk is woven on a traditional hand-operated loom.[35]

Bangladesh

TheRajshahi Divisionof northern Bangladesh is the hub of the country's silk industry. There are three types of silk produced in the region: mulberry, endi, and tassar.Bengalisilk was a major item of international trade for centuries. It was known as Ganges silk in medieval Europe. Bengal was the leading exporter of silk between the 16th and 19th centuries.[36]

Central Asia

The 7th century CE murals ofAfrasiyabinSamarkand,Sogdiana,show a Chinese Embassy carrying silk and a string of silkworm cocoons to the local Sogdian ruler.[37]

Middle East

In theTorah,a scarlet cloth item called in Hebrew "sheni tola'at" שני תולעת – literally "crimson of the worm" – is described as being used in purification ceremonies, such as those following a leprosy outbreak (Leviticus 14), alongsidecedar woodandhyssop(za'atar). Eminent scholar and leading medieval translator ofJewishsources and books of theBibleintoArabic,RabbiSaadia Gaon,translates this phrase explicitly as "crimson silk" – חריר קרמז حرير قرمز.

InIslamicteachings, Muslim men are forbidden to wear silk. Many religious jurists believe the reasoning behind the prohibition lies in avoiding clothing for men that can be considered feminine or extravagant.[38]There are disputes regarding the amount of silk a fabric can consist of (e.g., whether a small decorative silk piece on a cotton caftan is permissible or not) for it to be lawful for men to wear, but the dominant opinion of most Muslim scholars is that the wearing of silk by men is forbidden. Modern attire has raised a number of issues, including, for instance, the permissibility of wearing silkneckties,which are masculine articles of clothing.

Ancient Mediterranean

In theOdyssey,19.233, when Odysseus, while pretending to be someone else, is questioned by Penelope about her husband's clothing, he says that he wore a shirt "gleaming like the skin of a dried onion" (varies with translations, literal translation here)[39]which could refer to the lustrous quality of silk fabric. Aristotlewrote ofCoa vestis,a wild silk textile fromKos. Sea silkfrom certain large sea shells was also valued. TheRoman Empireknew of and traded in silk, and Chinese silk was the most highly priced luxury good imported by them.[24]During the reign of emperorTiberius,sumptuary lawswere passed that forbade men from wearing silk garments, but these proved ineffectual.[40]TheHistoria Augustamentions that the third-century emperorElagabaluswas the first Roman to wear garments of pure silk, whereas it had been customary to wear fabrics of silk/cotton or silk/linen blends.[41]Despite the popularity of silk, the secret of silk-making only reached Europe around AD 550, via theByzantine Empire.Contemporary accounts state that monks working for the emperorJustinian Ismuggled silkworm eggstoConstantinoplefrom China inside hollow canes.[42]All top-quality looms and weavers were located inside theGreat Palace complexin Constantinople, and the cloth produced was used in imperial robes or in diplomacy, as gifts to foreign dignitaries. The remainder was sold at very high prices.

Medieval and modern Europe

Italy was the most important producer of silk during the Medieval age. The first center to introduce silk production to Italy was the city ofCatanzaroduring the 11th century in the region ofCalabria.The silk of Catanzaro supplied almost all of Europe and was sold in a large market fair in the port ofReggio Calabria,to Spanish, Venetian, Genovese, and Dutch merchants. Catanzaro became the lace capital of the world with a large silkworm breeding facility that produced all the laces and linens used in the Vatican. The city was world-famous for its fine fabrication of silks, velvets, damasks, and brocades.[43]

Another notable center was the Italiancity-stateofLuccawhich largely financed itself through silk-production and silk-trading, beginning in the 12th century. Other Italian cities involved in silk production wereGenoa,Venice,andFlorence.ThePiedmontarea of Northern Italy became a major silk producing area when water-powered silk throwing machines were developed.[44]

TheSilk Exchange in Valenciafrom the 15th century—where previously in 1348 alsoperxal(percale) was traded as some kind of silk—illustrates the power and wealth of one of the great Mediterranean mercantile cities.[45][46]

Silk was produced in and exported from the province ofGranada,Spain, especially theAlpujarrasregion, until theMoriscos,whose industry it was, were expelled from Granada in 1571.[47][48]

Since the 15th century, silk production in France has been centered around the city ofLyonwhere many mechanic tools for mass production were first introduced in the 17th century.

James Iattempted to establish silk production in England, purchasing and planting 100,000 mulberry trees, some on land adjacent toHampton Court Palace,but they were of a species unsuited to the silk worms, and the attempt failed. In 1732 John Guardivaglio set up asilk throwingenterprise atLogwood mill in Stockport;in 1744, Burton Mill was erected inMacclesfield;and in 1753 Old Mill was built inCongleton.[49]These three towns remained the centre of the English silk throwing industry until silk throwing was replaced bysilk waste spinning.British enterprise also established silk filature inCyprusin 1928. In England in the mid-20th century, raw silk was produced atLullingstone Castlein Kent. Silkworms were raised and reeled under the direction ofZoe Lady Hart Dyke,later moving toAyot St Lawrencein Hertfordshire in 1956.[50]

DuringWorld War II,supplies of silk for UK parachute manufacture were secured from the Middle East byPeter Gaddum.[51]

- Medieval and modern Europe

-

Dress made from silk

-

Bed covered with silk

-

A hundred-year-old pattern of silk called "Almgrensrosen"

North America

Wild silk taken from the nests of native caterpillars was used by theAztecsto make containers and as paper.[55][9]Silkworms were introduced toOaxacafrom Spain in the 1530s and the region profited from silk production until the early 17th century, when the king of Spain banned export to protect Spain's silk industry. Silk production for local consumption has continued until the present day, sometimes spinning wild silk.[56]

KingJames Iintroduced silk-growing to the British colonies in America around 1619, ostensibly to discouragetobaccoplanting. TheShakersin Kentucky adopted the practice.

The history of industrial silk in the United States is largely tied to several smaller urban centers in the Northeast region. Beginning in the 1830s,Manchester, Connecticutemerged as the early center of the silk industry in America, when the Cheney Brothers became the first in the United States to properly raise silkworms on an industrial scale; today theCheney Brothers Historic Districtshowcases their former mills.[58]With themulberry treecraze of that decade, other smaller producers began raising silkworms. This economy particularly gained traction in the vicinity ofNorthampton, Massachusettsand its neighboringWilliamsburg,where a number of small firms and cooperatives emerged. Among the most prominent of these was the cooperative utopian Northampton Association for Education and Industry, of whichSojourner Truthwas a member.[59]Following the destructiveMill River Flood of 1874,one manufacturer,William Skinner,relocated his mill from Williamsburg to the then-new city ofHolyoke.Over the next 50 years he and his sons would maintain relations between the American silk industry and its counterparts in Japan,[60]and expanded their business to the point that by 1911, the Skinner Mill complex contained the largest silk mill under one roof in the world, and the brand Skinner Fabrics had become the largest manufacturer of silk satins internationally.[57][61]Other efforts later in the 19th century would also bring the new silk industry toPaterson, New Jersey,with several firms hiring European-born textile workers and granting it the nickname "Silk City" as another major center of production in the United States.

World War IIinterrupted the silk trade from Asia, and silk prices increased dramatically.[62]U.S. industry began to look for substitutes, which led to the use ofsyntheticssuch asnylon.Synthetic silks have also been made fromlyocell,a type ofcellulosefiber, and are often difficult to distinguish from real silk (seespider silkfor more on synthetic silks).

Malaysia

InTerengganu,which is now part ofMalaysia,a second generation of silkworm was being imported as early as 1764 for the country's silk textile industry, especiallysongket.[63]However, since the 1980s, Malaysia is no longer engaged in sericulture but does plant mulberry trees.

Vietnam

In Vietnamese legend, silk appeared in the first millennium AD and is still being woven today.

Production process

The process of silk production is known assericulture.[64]The entire production process of silk can be divided into several steps which are typically handled by different entities.[clarification needed]Extracting raw silk starts by cultivating the silkworms on mulberry leaves. Once the worms start pupating in their cocoons, these are dissolved in boiling water in order for individual long fibres to be extracted and fed into the spinning reel.[65]

To produce 1 kg of silk, 104 kg of mulberry leaves must be eaten by 3000 silkworms. It takes about 5000 silkworms to make a pure silkkimono.[66]: 104 The major silk producers areChina(54%) andIndia(14%).[67]Other statistics:[68]

| Top Ten Cocoons (Reelable) Producers – 2005 | ||||

|---|---|---|---|---|

| Country | Production(Int $1000) | Footnote | Production(1000 kg) | Footnote |

| People's Republic of China | 978,013 | C | 290,003 | F |

| India | 259,679 | C | 77,000 | F |

| Uzbekistan | 57,332 | C | 17,000 | F |

| Brazil | 37,097 | C | 11,000 | F |

| Iran | 20,235 | C | 6,088 | F |

| Thailand | 16,862 | C | 5,000 | F |

| Vietnam | 10,117 | C | 3,000 | F |

| Democratic People's Republic of Korea | 5,059 | C | 1,500 | F |

| Romania | 3,372 | C | 1,000 | F |

| Japan | 2,023 | C | 600 | F |

| No symbol = official figure, F = FAO estimate,*= Unofficial figure, C = Calculated figure; Production in Int $1000 have been calculated based on 1999–2001 international prices | ||||

The environmental impact of silk production is potentially large when compared with other natural fibers. Alife-cycle assessmentof Indian silk production shows that the production process has a large carbon and water footprint, mainly due to the fact that it is an animal-derived fiber and more inputs such as fertilizer and water are needed per unit of fiber produced.[69]

Properties

Physical properties

Silk fibers from theBombyx morisilkworm have atriangularcross sectionwith rounded corners, 5–10μmwide. The fibroin-heavy chain is composed mostly ofbeta-sheets,due to a 59-mer amino acid repeat sequence with some variations.[70]The flat surfaces of the fibrils reflectlightat many angles, giving silk a natural sheen. The cross-section from other silkworms can vary in shape and diameter: crescent-like forAnapheand elongated wedge fortussah.Silkworm fibers are naturally extruded from two silkworm glands as a pair of primary filaments (brin), which are stuck together, with sericin proteins that act likeglue,to form abave.[71]Bave diameters for tussah silk can reach 65 μm. See cited reference for cross-sectional SEM photographs.[70]

Silk has a smooth, soft texture that is not slippery, unlike manysynthetic fibers.

Silk is one of the strongest natural fibers, but it loses up to 20% of its strength when wet. It has a goodmoisture regainof 11%. Itselasticityis moderate to poor: if elongated even a small amount, it remains stretched. It can be weakened if exposed to too much sunlight. It may also be attacked by insects, especially if left dirty.

One example of the durable nature of silk over other fabrics is demonstrated by the recovery in 1840 of silk garments from awreck of 1782:'The most durable article found has been silk; for besides pieces of cloaks and lace, a pair of black satin breeches, and a large satin waistcoat with flaps, were got up, of which the silk was perfect, but the lining entirely gone... from the thread giving way... No articles of dress of woollen cloth have yet been found.'[72]

Silk is a poor conductor ofelectricityand thus susceptible tostatic cling.Silk has a high emissivity for infrared light, making it feel cool to the touch.[73]

Unwashed silk chiffon mayshrinkup to 8% due to a relaxation of the fiber macrostructure, so silk should either be washed prior to garment construction, ordry cleaned.Dry cleaning may still shrink the chiffon up to 4%. Occasionally, this shrinkage can be reversed by a gentle steaming with a press cloth. There is almost no gradual shrinkage nor shrinkage due to molecular-level deformation.

Natural and synthetic silk is known to manifestpiezoelectricproperties in proteins, probably due to its molecular structure.[74]

Silkworm silk was used as the standard for thedenier,a measurement oflinear densityin fibers. Silkworm silk therefore has a linear density of approximately 1 den, or 1.1dtex.

| Comparison of silk fibers[75] | Linear density (dtex) | Diameter (μm) | Coeff. variation |

|---|---|---|---|

| Moth:Bombyx mori | 1.17 | 12.9 | 24.8% |

| Spider:Argiope aurantia | 0.14 | 3.57 | 14.8% |

Chemical properties

Silk emitted by the silkworm consists of two main proteins,sericinandfibroin,fibroin being the structural center of the silk, and sericin being the sticky material surrounding it. Fibroin is made up of theamino acidsGly-Ser-Gly-Ala-Gly-Ala and formsbeta pleated sheets.Hydrogen bondsform between chains, and side chains are oriented above and below the plane of the hydrogen bond network.

The high proportion (50%) of glycine allows tight packing. This is because glycine has no side chain and is therefore unencumbered by steric strain. The addition of alanine and serine makes the fibres strong and resistant to breaking. This tensile strength is due to the many interceded hydrogen bonds, and when stretched the force is applied to these numerous bonds and they do not break.

Silk resists mostmineral acids,except forsulfuric acid,which dissolves it. It is yellowed by perspiration.Chlorine bleachwill also destroy silk fabrics.

Variants

Regenerated silk fiber

RSF is produced by chemically dissolving silkworm cocoons, leaving their molecular structure intact. The silk fibers dissolve into tiny thread-like structures known asmicrofibrils.The resulting solution is extruded through a small opening, causing the microfibrils to reassemble into a single fiber. The resulting material is reportedly twice as stiff as silk.[76]

Applications

Clothing

Silk'sabsorbencymakes it comfortable to wear in warm weather and while active. Its low conductivity keeps warm air close to the skin during cold weather. It is often used for clothing such asshirts,ties,blouses,formaldresses,high-fashion clothes,lining,lingerie,pajamas,robes,dress suits,sun dresses, and traditional Asian clothing. Silk is also excellent for insect-proof clothing, protecting the wearer frommosquitoesandhorseflies.

Fabrics that are often made from silk includesatin,charmeuse,habutai,chiffon,taffeta,crêpe de chine,dupioni,noil,tussah,andshantung,among others.

Furniture

Silk's attractive lustre and drape makes it suitable for manyfurnishingapplications. It is used forupholstery,wall coverings, window treatments (if blended with another fiber),rugs,bedding,and wall hangings.[77]

Industry

Silk had many industrial and commercial uses, such as inparachutes,bicycletires,comforter filling,andartillerygunpowderbags.[78]

Medicine

A special manufacturing process removes the outersericincoating of the silk, which makes it suitable as non-absorbablesurgical sutures.Sometimes wearing silk is suggested for people withatopic dermatitisbut, even though it is safe for the skin, it does not improve symptoms of the condition.[79][80][81]

Biomaterial

Silk began to serve as abiomedicalmaterial for sutures in surgeries as early as the second century CE.[82]In the past 30 years, it has been widely studied and used as abiomaterialdue to itsmechanical strength,biocompatibility,tunable degradation rate, ease to load cellular growth factors (for example, BMP-2), and its ability to be processed into several other formats such as films, gels, particles, and scaffolds.[83]Silks fromBombyx mori,a kind of cultivated silkworm, are the most widely investigated silks.[84]

Silks derived fromBombyx moriare generally made of two parts: thesilk fibroinfiber which contains a light chain of 25 kDa and a heavy chain of 350 kDa (or 390 kDa[85]) linked by a single disulfide bond[86]and a glue-like protein,sericin,comprising 25 to 30 percentage by weight. Silk fibroin contains hydrophobicbeta sheetblocks, interrupted by small hydrophilic groups. The beta-sheets contribute much to the high mechanical strength of silk fibers, which achieves 740 MPa, tens of times that ofpoly(lactic acid)and hundreds of times that ofcollagen.This impressive mechanical strength has made silk fibroin very competitive for applications in biomaterials. Indeed, silk fibers have found their way into tendon tissue engineering,[87]where mechanical properties matter greatly. In addition, mechanical properties of silks from various kinds of silkworms vary widely, which provides more choices for their use in tissue engineering.

Most products fabricated from regenerated silk are weak and brittle, with only ≈1–2% of the mechanical strength of native silk fibers due to the absence of appropriate secondary and hierarchical structure,

| Source Organisms[88] | Tensile strength

(g/den) |

Tensile modulus

(g/den) |

Breaking

strain (%) |

|---|---|---|---|

| Bombyx mori | 4.3–5.2 | 84–121 | 10.0–23.4 |

| Antheraea mylitta | 2.5–4.5 | 66–70 | 26–39 |

| Philosamia cynthia ricini | 1.9–3.5 | 29–31 | 28.0–24.0 |

| Coscinocera hercules | 5 ± 1 | 87 ± 17 | 12 ± 5 |

| Hyalophora euryalus | 2.7 ± 0.9 | 59 ± 18 | 11 ± 6 |

| Rothschildia hesperis | 3.3 ± 0.8 | 71 ± 16 | 10 ± 4 |

| Eupackardia calleta | 2.8 ± 0.7 | 58 ± 18 | 12 ± 6 |

| Rothschildia lebeau | 3.1 ± 0.8 | 54 ± 14 | 16 ± 7 |

| Antheraea oculea | 3.1 ± 0.8 | 57 ± 15 | 15 ± 7 |

| Hyalophora gloveri | 2.8 ± 0.4 | 48 ± 13 | 19 ± 7 |

| Copaxa multifenestrata | 0.9 ± 0.2 | 39 ± 6 | 4 ± 3 |

Biocompatibility

Biocompatibility, i.e., to what level the silk will cause an immune response, is a critical issue for biomaterials. The issue arose during its increasing clinical use. Wax or silicone is usually used as a coating to avoid fraying and potential immune responses[83]when silk fibers serve as suture materials. Although the lack of detailed characterization of silk fibers, such as the extent of the removal of sericin, the surface chemical properties of coating material, and the process used, make it difficult to determine the real immune response of silk fibers in literature, it is generally believed that sericin is the major cause of immune response. Thus, the removal of sericin is an essential step to assure biocompatibility in biomaterial applications of silk. However, further research fails to prove clearly the contribution of sericin to inflammatory responses based on isolated sericin and sericin based biomaterials.[89]In addition, silk fibroin exhibits an inflammatory response similar to that of tissue culture plastic in vitro[90][91]when assessed with human mesenchymalstem cells(hMSCs) or lower than collagen and PLA when implant rat MSCs with silk fibroin films in vivo.[91]Thus, appropriate degumming and sterilization will assure the biocompatibility of silk fibroin, which is further validated by in vivo experiments on rats and pigs.[92]There are still concerns about the long-term safety of silk-based biomaterials in the human body in contrast to these promising results. Even though silk sutures serve well, they exist and interact within a limited period depending on the recovery of wounds (several weeks), much shorter than that in tissue engineering. Another concern arises from biodegradation because the biocompatibility of silk fibroin does not necessarily assure the biocompatibility of the decomposed products. In fact, different levels of immune responses[93][94]and diseases[95]have been triggered by the degraded products of silk fibroin.

Biodegradability

Biodegradability(also known asbiodegradation)—the ability to be disintegrated by biological approaches, including bacteria, fungi, and cells—is another significant property of biomaterials. Biodegradable materials can minimize the pain of patients from surgeries, especially in tissue engineering, since there is no need for surgery in order to remove the implanted scaffold. Wang et al.[96]showed the in vivo degradation of silk via aqueous 3D scaffolds implanted into Lewis rats.Enzymesare the means used to achieve degradation of silk in vitro. Protease XIV fromStreptomyces griseusandα-chymotrypsinfrom bovinepancreasesare two popular enzymes for silk degradation. In addition,gamma radiation,as well ascell metabolism,can also regulate the degradation of silk.

Compared with synthetic biomaterials such aspolyglycolidesandpolylactides,silk is advantageous in some aspects of biodegradation. The acidic degraded products of polyglycolides and polylactides will decrease the pH of the ambient environment and thus adversely influence the metabolism of cells, which is not an issue for silk. In addition, silk materials can retain strength over a desired period from weeks to months on an as-needed basis, by mediating the content ofbeta sheets.

Genetic modification

Genetic modificationof domesticated silkworms has been used to alter the composition of the silk.[97]As well as possibly facilitating the production of more useful types of silk, this may allow other industrially or therapeutically useful proteins to be made by silkworms.[98]

Cultivation

Silkmothslay eggs on specially prepared paper. The eggs hatch and the caterpillars (silkworms) are fed freshmulberryleaves. After about 35 days and 4 moltings, the caterpillars are 10,000 times heavier than when hatched and are ready to begin spinning a cocoon. A straw frame is placed over the tray of caterpillars, and each caterpillar begins spinning a cocoon by moving its head in a pattern. Two glands produce liquid silk and force it through openings in the head called spinnerets. Liquid silk is coated in sericin, a water-soluble protective gum, and solidifies on contact with the air. Within 2–3 days, the caterpillar spins about one mile (1.6 km) of filament and is completely encased in a cocoon. The silk farmers then heat the cocoons to kill them, leaving some tometamorphoseinto moths to breed the next generation of caterpillars. Harvested cocoons are then soaked in boiling water to soften the sericin holding the silk fibers together in a cocoon shape. The fibers are then unwound to produce a continuous thread. Since a single thread is too fine and fragile for commercial use, anywhere from three to ten strands are spun together to form a single thread of silk.[99]

Animal rights

As the process of harvesting the silk from the cocoon kills the larvae by boiling, sericulture has been criticized by animal welfare activists,[100]includingPeople for the Ethical Treatment of Animals(PETA), who urge people not to buy silk items.[101]

Mahatma Gandhiwas critical of silk production because of hisAhimsa(non-violent) philosophy, which led to the promotion of cotton andAhimsa silk,a type ofwild silkmade from the cocoons of wild and semi-wild silk moths.[102]

See also

References

Citations

- ^"Silk".The Free Dictionary By Farlex.Archivedfrom the original on 3 July 2021.Retrieved23 May2012.

- ^abSutherland TD, Young JH, Weisman S, Hayashi CY, Merritt DJ (2010). "Insect silk: one name, many materials".Annual Review of Entomology.55:171–88.doi:10.1146/annurev-ento-112408-085401.PMID19728833.

- ^Walker AA, Weisman S, Church JS, Merritt DJ, Mudie ST, Sutherland TD (2012)."Silk from Crickets: A New Twist on Spinning".PLOS ONE.7(2): e30408.Bibcode:2012PLoSO...730408W.doi:10.1371/journal.pone.0030408.PMC3280245.PMID22355311.

- ^Warner, Frank (1911)..InChisholm, Hugh(ed.).Encyclopædia Britannica.Vol. 25 (11th ed.). Cambridge University Press. p. 97.

- ^"Silk".Etymonline.Archivedfrom the original on 14 December 2013.Retrieved27 August2012.

- ^Sindya N. Bhanoo (20 May 2011)."Silk Production Takes a Walk on the Wild Side".New York Times.Archivedfrom the original on 9 November 2012.Retrieved26 May2011.

- ^"Chance meeting leads to creation of antibiotic spider silk".phys.org.Archivedfrom the original on 26 August 2018.Retrieved13 September2019.

- ^"Cobweb Art a Triumph of Whimsy Over Practicality: Northwestern University News".www.northwestern.edu.Archivedfrom the original on 4 July 2019.Retrieved13 September2019.

- ^abHogue, Charles Leonard (1993).Latin American insects and entomology.Berkeley: University of California Press. pp.325.ISBN978-0520078499.OCLC25164105.

Silk swaths gathered from the large hammock-net cocoons of Gloveria psidii (= Sagana sapotoza) and pasted together to form a kind of hard cloth, or paper, were an important trade item in Mexico at the time of Moctezuma II

- ^Hill (2004). Appendix E.

- ^Hill (2009). "Appendix C: Wild Silks", pp.477–480.

- ^Gheysens, T; Collins, A; Raina, S; Vollrath, F; Knight, D (2011)."Demineralization enables reeling of Wild Silkmoth cocoons"(PDF).Biomacromolecules.12(6): 2257–66.doi:10.1021/bm2003362.hdl:1854/LU-2153669.PMID21491856.Archived(PDF)from the original on 22 September 2017.

- ^abcVainker, Shelagh (2004).Chinese Silk: A Cultural History.Rutgers University Press.pp. 20, 17.ISBN978-0813534466.

- ^"Silk: History".Columbia Electronic Encyclopedia(Sixth ed.). Columbia University Press.Archivedfrom the original on 16 December 2008.

- ^"Oldest Evidence of Silk Found in 8,500-Year-Old Tombs".Live Science.10 January 2017.Archivedfrom the original on 13 October 2017.Retrieved13 October2017.

- ^"Prehistoric silk found in Henan".The Institute of Archaeology, Chinese Academy of Social Sciences (IA CASS).Archivedfrom the original on 4 January 2017.Retrieved4 October2017.

- ^"Textile Exhibition: Introduction".Asian art.Archivedfrom the original on 8 September 2007.

- ^Lyons, Martyn (2011).Books: A Living History.Los Angeles: Getty Publications. p. 18.ISBN978-1606060834.

- ^ab"Chinese archaeologists make ground-breaking textile discovery in 2,500-year-old tomb".People's Daily Online.Archivedfrom the original on 13 October 2007.Retrieved26 August2007.

- ^Lubec, G.; J. Holaubek; C. Feldl; B. Lubec; E. Strouhal (4 March 1993)."Use of silk in ancient Egypt".Nature.362(6415): 25.Bibcode:1993Natur.362...25L.doi:10.1038/362025b0.S2CID1001799.Archived from the original on 20 September 2007.Retrieved3 May2007.

{{cite journal}}:CS1 maint: unfit URL (link)) - ^Kundu, Subhas (24 March 2014).Silk Biomaterials for Tissue Engineering and Regenerative Medicine.Elsevier Science. pp. 3–.ISBN978-0-85709-706-4.

- ^Hill (2009). Appendix A: "Introduction of Silk Cultivation to Khotan in the 1st Century CE", pp. 466–467.

- ^"History of Sericulture"(PDF).Government of Andhra Pradesh (India) – Department of Sericulture. Archived fromthe original(PDF)on 21 July 2011.Retrieved7 November2010.

- ^abcGarthwaite, Gene Ralph (2005).The Persians.Oxford & Carlton:Blackwell Publishing, Ltd.p. 78.ISBN978-1-55786-860-2.

- ^"Japanese Silk".JapanTackle.

- ^http://gallica.bnf.fr/ark:/12148/bpt6k3024c/f443.tableGallica

- ^ab"Why Japan, Not China, Was the First to Develop in East Asia: Lessons from Sericulture, 1850–1937"(PDF).Debin Ma.

- ^"Wallace Carothers and the Development of Nylon - Landmark".

- ^Anthony H. Gaddum, "Silk",Business and Industry Review,(2006).In Encyclopædia Britannica

- ^abBall, Philip (17 February 2009)."Rethinking silk's origins".Nature.457(7232): 945.doi:10.1038/457945a.PMID19238684.S2CID4390646.

- ^Good, I.L.; Kenoyer, J.M.; Meadow, R.H. (2009)."New evidence for early silk in the Indus civilization"(PDF).Archaeometry.50(3): 457.doi:10.1111/j.1475-4754.2008.00454.x.Archived(PDF)from the original on 9 August 2017.Retrieved20 April2018.

- ^Tn SericultureArchived19 August 2014 at theWayback Machine.Tn Sericulture (30 June 2014).

- ^"Silk city to come up near B'lore".Deccan Herald.17 October 2009.Archivedfrom the original on 15 July 2015.Retrieved22 April2015.

- ^"Tamil Nadu News: Tamil Nadu's first automatic silk reeling unit opened".The Hindu.24 August 2008. Archived fromthe originalon 19 October 2013.Retrieved9 November2013.

- ^About Thai silkArchived9 May 2007 at theWayback Machinefrom World of Thai Silk (commercial)

- ^Silk – BanglapediaArchived4 March 2016 at theWayback Machine.En.banglapedia.org (10 March 2015). Retrieved on 2016-08-02.

- ^abWhitfield, Susan(2004).The Silk Road: Trade, Travel, War and Faith.British Library. Serindia Publications, Inc. p. 110.ISBN978-1-932476-13-2.Archivedfrom the original on 26 April 2016.Retrieved22 October2020.

- ^"Silk: Why It Is Haram for Men".23 September 2003. Archived fromthe originalon 2 March 2007.Retrieved6 January2007.

- ^Odyssey19233–234: τὸν δὲ χιτῶν' ἐνόησα περὶ χροῒ σιγαλόεντα, οἷόν τε κρομύοιο λοπὸν κάτα ἰσχαλέοιο· = "And I [=Odysseus

- ^Tacitus(1989).Annals.Cambridge University Press.ISBN978-0-521-31543-2.Archivedfrom the original on 30 June 2020.Retrieved28 August2020.

- ^Historia Augusta Vita Heliogabali.Book 26.1.

- ^Procopius(1928).History of the Wars.Book 8.17.ISBN978-0-674-992399.

- ^"Italy – Calabria, Catanzaro".Office of Tourism.Archived fromthe originalon 21 August 2015.

- ^Postrel, Virginia (2020).The Fabric of Civilization.New York: Basic Books. pp. 55–59.ISBN9781541617629.

- ^"La Lonja de la Seda de Valencia".UNESCO World Heritage Centre.Whc.unesco.org.Archivedfrom the original on 14 May 2011.Retrieved10 April2011.

- ^Diccionari Aguiló: materials lexicogràfics / aplegats per Marià Aguiló i Fuster; revisats i publicats sota la cura de Pompeu Fabra i Manuel de Montoliu, page 134,Institut d'Estudis Catalans,Barcelona 1929.

- ^Delgado, José Luis (8 October 2012)"La seda de Granada era la mejor"Archived26 August 2014 at theWayback Machine,Granada Hoy

- ^Intxausti, Aurora (1 May 2013)"La Alpujarra poseía 4.000 telares de seda antes de la expulsión de los moriscos"Archived26 August 2014 at theWayback Machine,El País.

- ^Callandine 1993

- ^"Lullingstone Silk Farm".www.lullingstonecastle.co.uk.Archived fromthe originalon 10 January 2015.Retrieved29 September2016.

- ^BOND, Barbara A (2014)."MI9's escape and evasion mapping programme 1939-1945"(PDF).University of Plymouth.Archived(PDF)from the original on 19 January 2021.Retrieved4 March2020.

- ^Nash, Eric P. (30 July 1995)."STYLE; Dressed to Kill".The New York Times.Archivedfrom the original on 9 November 2012.Retrieved12 October2011.

- ^Huzjan, Vladimir (July 2008)."Pokušaj otkrivanja nastanka i razvoja kravate kao riječi i odjevnoga predmeta"[The origin and development of the tie (kravata) as a word and as a garment].Povijesni prilozi(in Croatian).34(34): 103–120.ISSN0351-9767.Archivedfrom the original on 29 June 2012.Retrieved17 October2011.

- ^"Silk Production in Konavle".Archivedfrom the original on 1 May 2015.Retrieved22 April2015.

- ^P.G., Kevan; R.A., Bye (1991)."natural history, sociobiology, and ethnobiology of Eucheira socialis Westwood (Lepidoptera: Pieridae), a unique and little-known butterfly from Mexico".Entomologist.ISSN0013-8878.Archivedfrom the original on 28 July 2020.Retrieved26 September2018.

- ^de Avila, Alejandro (1997). Klein, Kathryn (ed.).The Unbroken Thread: Conserving the Textile Traditions of Oaxaca(PDF).Los Angeles: The Getty Conservation Institute. pp. 125–126.Archived(PDF)from the original on 6 December 2020.Retrieved26 September2018.

- ^ab"The Largest Silk Mill in the World; The Story of Skinner Silks and Satins".Silk.Vol. 5, no. 6. New York: Silk Publishing Company. May 1912. pp. 62–64.Archivedfrom the original on 29 January 2020.Retrieved14 December2018.

- ^"Cheney Brothers Historic District".National Historic Landmark summary listing.National Park Service. Archived fromthe originalon 8 October 2007.Retrieved3 October2007.

- ^Owens, Jody (12 April 2002)."Becoming Sojourner Truth: The Northampton Years".Silk in Northampton.Smith College. Archived fromthe originalon 17 August 2003.

- ^For discussion on W. Skinner II's relations with Japanese ministers and merchant-traders, seeLindsay Russell, ed. (1915).America to Japan: A Symposium of Papers by Representative Citizens of the United States on the Relations between Japan and America and on the Common Interests of the Two Countries.New York: G.P. Putnam's Sons; The Knickerbocker Press; The Japan Society. p. 66.Archivedfrom the original on 29 December 2019.Retrieved14 December2018.

- "Luncheon to Commissioner Shito".The American Silk Journal.XXXIV.Silk Association of America: 32. May 1915.Archivedfrom the original on 23 December 2019.Retrieved14 December2018.

- Reischauer, Haru Matsukata (1986)."Starting the Silk Trade".Samurai and Silk: A Japanese and American Heritage.Cambridge, Mass.: Harvard University Press. pp. 207–209.ISBN9780674788015.Archivedfrom the original on 30 December 2019.Retrieved14 December2018.

- ^Thibodeau, Kate Navarra (8 June 2009)."William Skinner & Holyoke's Water Power".Valley Advocate.Northampton, Mass.Archivedfrom the original on 31 December 2019.Retrieved14 December2018.

- ^Weatherford, D (2009).American Women During World War II: An Encyclopedia.Routledge. p. 97.ISBN978-0415994750.

- ^Mohamad, Maznah (1996).The Malayhandloom weavers:a study of the rise and decline of traditional.Institute of Southeast Asian Studies.ISBN9789813016996.Retrieved9 November2013.

- ^Pedigo, Larry P.; Rice, Marlin E. (2014).Entomology and Pest Management: Sixth Edition.Waveland Press.ISBN978-1478627708.

- ^Bezzina, Neville."Silk Production Process".senature.com. Archived fromthe originalon 29 June 2012.

- ^Fritz, Anne and Cant, Jennifer (1986).Consumer Textiles.Oxford University PressAustralia. Reprint 1987.ISBN0-19-554647-4.

- ^"Mulberry Silk – Textile Fibres – Handloom Textiles | Handwoven Fabrics | Natural Fabrics | Cotton clothes in Chennai".Brasstacksmadras.com. Archived fromthe originalon 9 November 2013.Retrieved9 November2013.

- ^"Statistics".inserco.org.Archivedfrom the original on 26 January 2016.

- ^Astudillo, Miguel F.; Thalwitz, Gunnar; Vollrath, Fritz (October 2014). "Life cycle assessment of Indian silk".Journal of Cleaner Production.81:158–167.Bibcode:2014JCPro..81..158A.doi:10.1016/j.jclepro.2014.06.007.

- ^abLewin, Menachem, ed. (2007).Handbook of fiber chemistry(3rd ed.). Boca Raton: CRC/Taylor & Francis. pp. 438–441.ISBN9780824725655.

- ^Burnham, Dorothy K. (1980).Warp and weft: a textile terminology.Toronto: Royal Ontario Museum. p. 3.ISBN978-0-88854-256-4.

- ^The Times,London, article CS117993292, 12 October 1840.

- ^Venere, Emil (31 January 2018)."Silk fibers could be high-tech 'natural metamaterials'".Phys.org.Archivedfrom the original on 1 February 2018.Retrieved2 February2018.

- ^"Piezoelectricity in Natural and Synthetic Silks"(PDF).Archived(PDF)from the original on 20 July 2011.Retrieved28 April2010.

- ^Ko, Frank K.; Kawabata, Sueo; Inoue, Mari; Niwa, Masako."Engineering Properties of Spider Silk"(PDF).Archived(PDF)from the original on 31 March 2010.Retrieved9 July2010.

- ^"To almost match spider silk, scientists regenerate silkworm silk".newatlas.com.10 November 2017.Archivedfrom the original on 10 November 2017.Retrieved18 December2017.

- ^Murthy, H. V. Sreenivasa (2018).Introduction to Textile Fibres.WPI India.ISBN9781315359335.

- ^"Silk Powder or Cartridge Bag Cloth".americanhistory.si.edu.Archivedfrom the original on 9 November 2017.Retrieved30 May2017.

- ^Jaros J, Wilson C, Shi VY (August 2020). "Fabric Selection in Atopic Dermatitis: An Evidence-Based Review".American Journal of Clinical Dermatology.21(4): 467–482.doi:10.1007/s40257-020-00516-0.PMID32440827.S2CID218761019.

- ^Eczema in children: uncertainties addressed(Report). NIHR Evidence. 19 March 2024.doi:10.3310/nihrevidence_62438.

- ^Thomas KS, Bradshaw LE, Sach TH, Cowdell F, Batchelor JM, Lawton S, Harrison EF, Haines RH, Ahmed A, Dean T, Burrows NP, Pollock I, Buckley HK, Williams HC, Llewellyn J, Crang C, Grundy JD, Guiness J, Gribbin A, Wake EV, Mitchell EJ, Brown SJ, Montgomery AA (April 2017)."Randomised controlled trial of silk therapeutic garments for the management of atopic eczema in children: the CLOTHES trial".Health Technology Assessment.21(16): 1–260.doi:10.3310/hta21160.PMC5410632.PMID28409557.

- ^Muffly, Tyler; Tizzano, Anthony; Walters, Mark (March 2011)."The history and evolution of sutures in pelvic surgery".Journal of the Royal Society of Medicine.104(3): 107–12.doi:10.1258/jrsm.2010.100243.PMC3046193.PMID21357979.

Galen also recommended using silk suture when available.

- ^abRockwood, Danielle N; Preda, Rucsanda C; Yücel, Tuna; Wang, Xiaoqin; Lovett, Michael L; Kaplan, David L (2011)."Materials fabrication fromBombyx morisilk fibroin ".Nature Protocols.6(10): 1612–1631.doi:10.1038/nprot.2011.379.PMC3808976.PMID21959241.

- ^Altman, Gregory H; Diaz, Frank; Jakuba, Caroline; Calabro, Tara; Horan, Rebecca L; Chen, Jingsong; Lu, Helen; Richmond, John; Kaplan, David L (1 February 2003). "Silk-based biomaterials".Biomaterials.24(3): 401–416.CiteSeerX10.1.1.625.3644.doi:10.1016/S0142-9612(02)00353-8.PMID12423595.

- ^Vepari, Charu;Kaplan, David L.(1 August 2007)."Silk as a biomaterial".Progress in Polymer Science.Polymers in Biomedical Applications.32(8–9): 991–1007.doi:10.1016/j.progpolymsci.2007.05.013.PMC2699289.PMID19543442.

- ^Zhou, Cong-Zhao; Confalonieri, Fabrice; Medina, Nadine; Zivanovic, Yvan; Esnault, Catherine; Yang, Tie; Jacquet, Michel; Janin, Joel; Duguet, Michel (15 June 2000)."Fine organization ofBombyx morifibroin heavy chain gene ".Nucleic Acids Research.28(12): 2413–2419.doi:10.1093/nar/28.12.2413.PMC102737.PMID10871375.

- ^Kardestuncer, T; McCarthy, M B; Karageorgiou, V; Kaplan, D; Gronowicz, G (2006). "RGD-tethered Silk Substrate Stimulates the Differentiation of Human Tendon Cells".Clinical Orthopaedics and Related Research.448:234–239.doi:10.1097/01.blo.0000205879.50834.fe.PMID16826121.S2CID23123.

- ^Kundu, Banani; Rajkhowa, Rangam; Kundu, Subhas C.; Wang, Xungai (1 April 2013). "Silk fibroin biomaterials for tissue regenerations".Advanced Drug Delivery Reviews.Bionics – Biologically inspired smart materials.65(4): 457–470.doi:10.1016/j.addr.2012.09.043.PMID23137786.

- ^Zhang, Yaopeng; Yang, Hongxia; Shao, Huili; Hu, Xuechao (5 May 2010)."Antheraea pernyiSilk Fiber: A Potential Resource for Artificially Biospinning Spider Dragline Silk".Journal of Biomedicine and Biotechnology.2010:683962.doi:10.1155/2010/683962.PMC2864894.PMID20454537.

- ^Wray, Lindsay S.; Hu, Xiao; Gallego, Jabier; Georgakoudi, Irene; Omenetto, Fiorenzo G.; Schmidt, Daniel; Kaplan, David L. (1 October 2011)."Effect of processing on silk-based biomaterials: Reproducibility and biocompatibility".Journal of Biomedical Materials Research Part B: Applied Biomaterials.99B(1): 89–101.doi:10.1002/jbm.b.31875.PMC3418605.PMID21695778.

- ^abMeinel, Lorenz; Hofmann, Sandra; Karageorgiou, Vassilis; Kirker-Head, Carl; McCool, John; Gronowicz, Gloria; Zichner, Ludwig; Langer, Robert; Vunjak-Novakovic, Gordana (1 January 2005). "The inflammatory responses to silk films in vitro and in vivo".Biomaterials.26(2): 147–155.doi:10.1016/j.biomaterials.2004.02.047.PMID15207461.

- ^Fan, Hongbin; Liu, Haifeng; Toh, Siew L.; Goh, James C.H. (2009). "Anterior cruciate ligament regeneration using mesenchymal stem cells and silk scaffold in large animal model".Biomaterials.30(28): 4967–4977.doi:10.1016/j.biomaterials.2009.05.048.PMID19539988.

- ^Minoura, N.; Aiba, S.; Higuchi, M.; Gotoh, Y.; Tsukada, M.; Imai, Y. (17 March 1995). "Attachment and growth of fibroblast cells on silk fibroin".Biochemical and Biophysical Research Communications.208(2): 511–516.doi:10.1006/bbrc.1995.1368.PMID7695601.

- ^Gellynck, Kris; Verdonk, Peter C. M.; Van Nimmen, Els; Almqvist, Karl F.; Gheysens, Tom; Schoukens, Gustaaf; Van Langenhove, Lieva; Kiekens, Paul; Mertens, Johan (1 November 2008). "Silkworm and spider silk scaffolds for chondrocyte support".Journal of Materials Science: Materials in Medicine.19(11): 3399–3409.doi:10.1007/s10856-008-3474-6.PMID18545943.S2CID27191387.

- ^Lundmark, Katarzyna; Westermark, Gunilla T.; Olsén, Arne; Westermark, Per (26 April 2005)."Protein fibrils in nature can enhance amyloid protein A amyloidosis in mice: Cross-seeding as a disease mechanism".Proceedings of the National Academy of Sciences of the United States of America.102(17): 6098–6102.Bibcode:2005PNAS..102.6098L.doi:10.1073/pnas.0501814102.PMC1087940.PMID15829582.

- ^Wang, Yongzhong; Rudym, Darya D.; Walsh, Ashley; Abrahamsen, Lauren; Kim, Hyeon-Joo; Kim, Hyun S.; Kirker-Head, Carl; Kaplan, David L. (2008)."In vivo degradation of three-dimensional silk fibroin scaffolds".Biomaterials.29(24–25): 3415–3428.doi:10.1016/j.biomaterials.2008.05.002.PMC3206261.PMID18502501.

- ^Kojima, K.; Kuwana, Y.; Sezutsu, H.; Kobayashi, I.; Uchino, K.; Tamura, T.; Tamada, Y. (2007). "A new method for the modification of fibroin heavy chain protein in the transgenic silkworm".Bioscience, Biotechnology, and Biochemistry.71(12): 2943–2951.doi:10.1271/bbb.70353.PMID18071257.S2CID44520735.

- ^Tomita, Masahiro (April 2011). "Transgenic silkworms that weave recombinant proteins into silk cocoons".Biotechnology Letters.33(4): 645–654.doi:10.1007/s10529-010-0498-z.ISSN1573-6776.PMID21184136.S2CID25310446.

- ^Gleason, Carrie (2006)The Biography of Silk.Crabtree Publishing Company. p. 12.ISBN0778724875.

- ^Stancati, Margherita (4 January 2011)."Taking the Violence Out of Silk".Wall Street Journal.Archivedfrom the original on 22 January 2015.Retrieved22 January2015.

- ^"Down and Silk: Birds and Insects Exploited for Feathers and Fabric".PETA.19 March 2004.Archivedfrom the original on 1 February 2014.Retrieved23 January2014.

Silk Production Causes Painful Death for Insects

- ^Alexander, Horace Gundry; Centenary, National Committee for the Gandhi (1968).Mahatma Gandhi: 100 years.Gandhi Peace Foundation;Orient Longmans.

Bibliography

- Callandine, Anthony (1993). "Lombe's Mill: An Exercise in reconstruction".Industrial Archaeology Review.XVI(1).ISSN0309-0728.

- Hill, John E. (2004).The Peoples of the West from the WeilüeNgụy lượcby Yu HuanNgư hoạn:A Third Century Chinese Account Composed between 239 and 265 AD.Draft annotated English translation. Appendix E.

- Hill, John E. (2009)Through the Jade Gate to Rome: A Study of the Silk Routes during the Later Han Dynasty, 1st to 2nd centuries CE.BookSurge, Charleston, South Carolina.ISBN978-1-4392-2134-1.

- Magie, David (1924).Historia Augusta Life of Heliogabalus.Loeb Classical Texts No. 140: Harvard University Press.ISBN978-0674991552.

Further reading

- Feltwell, John (1990).The Story of Silk.Alan Sutton Publishing.ISBN0-86299-611-2.

- Good, Irene (December 1995). "On the Question of Silk in Pre-Han Eurasia".Antiquity.Vol. 69, Number 266. pp. 959–968.

- Kadolph, Sara J. (2007).Textiles(10th ed.). Upper Saddle River: Pearson Prentice Hall. pp. 76–81.

- Kuhn, Dieter (1995). "Silk Weaving in Ancient China: From Geometric Figures to Patterns of Pictorial Likeness".Chinese Science.12. pp. 77–114.

- Rayner, Hollins (1903).Silk throwing and waste silk spinning.Scott, Greenwood, Van Nostrand.OL7174062M.

- Ricci, G.; et al. (2004). "Clinical Effectiveness of a Silk Fabric in the Treatment of Atopic Dermatitis".British Journal of Dermatology.Issue 150. pp. 127–131.

- Sung, Ying-Hsing. 1637. "Chapter 2. Clothing materials".Chinese Technology in the Seventeenth Century – T'ien-kung K'ai-wu.Translated and annotated by E-tu Zen Sun and Shiou-chuan Sun. Pennsylvania State University Press, 1966. Reprint: Dover, 1997.

- Liu, Xinru(1996).Silk and Religion: An Exploration of Material Life and the Thought of People, AD 600–1200.Oxford University Press.

- Liu, Xinru(2010).The Silk Road in World History.Oxford University Press.ISBN978-0-19-516174-8;ISBN978-0-19-533810-2(pbk).