Steam springsorsteam suspensionare a form ofsuspensionused for someearly steam locomotivesdesigned and built byGeorge Stephenson.They were only briefly used and may have been used for fewer than ten locomotives.

Requirements for suspension

editEarly railways usedcast-ironfishbelly rails.These werebrittleand prone to cracking under shock loads. The new steam locomotives of the 1820s were much heavier than the horse-drawn wagons of earlierplateways.Locomotives of this period also used vertical cylinders set within the boiler. The vertical forces of the moving pistons further gave rise tohammer blow,which increased the load on the rails.

A further reason for suspension was to improve the frictional contact between the wheels and rail. This relied upon maintaining a good contact, thus requiring good suspension of the wheels over the uneven track.[2]The ability of an 'adhesion-hauled' locomotive to draw a train was much questioned at this time, as it was thought that the friction between a smooth iron wheel and the rail would be inadequate. Some designers, such asBlenkinsopwith hisSalamancathought that a system of geared teeth would be necessary. Stephenson believed that, provided a good contact could be maintained between wheel and rail, frictional adhesion alone would be adequate.

Steam springs

editAt the time of these early locomotives there was not yet a way of forging an adequate steel spring to carry the weight of a locomotive. High quality steel had been available sinceHuntsman'scrucible process,but it was still so expensive as to be regarded as 'a semi-precious metal'.[4]It would be another forty years beforeBessemer's convertermade cheap bulk steel available. A similar problem affectedsafety valves,causing them to rely on dead weights orHackworth's bulkystack of leaf springs,[5]rather than the ubiquitous steelcoil springthat would appear later.

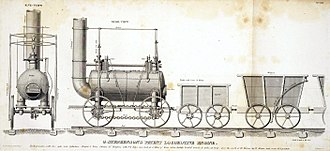

Stephenson's 'steam suspension' provided each wheel with its own 'steam spring'. Vertical cylinders were set into the base of the boiler, above each axle and offset in pairs to the sides. The chassis or frames of Stephenson's locomotives provided little structural strength, most of which came from the shell of theboiler.Inside each cylinder a piston carried the load of the axle and pressed upwards against steam pressure within the boiler.[6]A piston of only a few inches in diameter was sufficient to balance the locomotive's weight. The axlebox bearings could slide vertically within hornblocks attached to the wooden frame beneath the boiler.

Pistonseals were a perennial problem at this time. Those for large stationary engines, working at low pressures, were sealed by a variety of methods including leather cup washers, pools of standing water and even a poultice of cow dung. As working pressures increased, which had been an essential part of turning thestationary steam engineinto the mobilesteam locomotive,demands on the piston seal increased further. Pistons were now mostly sealed by havingoakumrope wrapped around them in a groove, often smeared withtallow.Keeping the rope seal moist, thus swollen, was recognised as an important factor in achieving a good seal. As the steam spring cylinders were in the lower part of the boiler, below the water line, it was expected that they would seal well. Despite this, they continued to give trouble with leakage and were eventually removed and replaced with iron or steel leaf springs.[7]Woodin 1831 illustrates one of the Killingworth locomotives, now fitted with metal leaf springs and alsocoupling rods.[8][9]

Killingworth Colliery locomotives

editGeorge Stephenson's first locomotive was theBlücherof 1814.[6][i]This was a four-wheeled locomotive with the wheels coupled byspur gears.It suffered from poor traction on the relatively new technology ofedge railswith flanged wheels, put down to the problem of maintaining a good contact with them. It was the first of a batch of early Stephenson locomotives known as the 'Killingworth Colliery locomotives'.[ii]Stephenson's next design was a development of this, still with four wheels, but now using achain driveto couple them together.[11]This was his first locomotive to use steam springs.[1]

The Duke

editStephenson had gained a reputation as a builder of locomotives and was approached to build the first locomotive for use in Scotland, on theKilmarnock and Troon Railway.The Dukewas larger, with six wheels, and used the same chain drive and steam springs as the Killingworth locomotives. As this locomotive was to be built for an outside customer, Stephenson could no longer use the workshop facilities at Killingworth and so it was built at his friendWilliam Losh'sWalker Iron WorksinNewcastle.[7]Improvements of this locomotive were detailed in a patent, jointly filed with Losh, on 30 September 1816.

The Dukewas probably completed in 1817[12]and ran at Kilmarnock, but seems to have continued the problems of rail breakage. It was sold tothe Earl of Elginin October 1824 for his railway inFife,but being too heavy for the rails was used as a stationary pumping engine in a quarry atCharlestown,and from 1830 at a colliery nearDunfermline;its subsequent fate is unrecorded.

Most Scottish depictions ofThe Dukeare inaccurate, being based on the Killingworth locomotives or evenStephenson'sRocket,but in 1914 a commemorative silver model was made for the centenary and this alone seems accurate, showing the six wheels and the cylinders of the steam springs.[13]

Hetton Colliery locomotives

editFive locomotives were built forHetton Collierybetween 1820 and 1822, four of which were named:Hettton,Dart,TallyhoandStar.[7][14]These were of similar design toThe Duke,but four-wheeled with 3' 9 "wheels. They were built with steam springs, later removed owing to problems with steam leakage.[7]

In 1852,Lyonwas built as a replica of these early Hetton locomotives.

Later locomotives andLocomotion

editLater locomotives abandoned the steam springs. ForLocomotionon theStockton and Darlington Railwayin 1825 there was no springing provided. Although there were no springs, side-to-side compensation was provided to keep good contact between rails and wheels. One of the axles was carried in a'cannon box' bearingthat was pivoted centrally and could tilt from side to side.[15]Although not giving a stable ride for the locomotive, it did allow the wheels to follow uneven track. The presence of this cannon box between the wheels also prevented the previous use of the central drive chain and so Stephenson adopted the now ubiquitouscoupling rodsfor his first time. Reducing the travel of the suspension, compared to that with steam springs, also made the provision of free-running coupling rods easier, as it avoided the change in effective wheelbase when one axle moved relative to the other.

The unsprung ride broke the original eight-spoked cast-iron wheels and so these were replaced by Hackworth with his distinctivetwo piece cast-iron disc wheels,trued by wooden wedges between the concentric parts.[15]Rail breakage had been reduced by this time with the use of stronger rails. These new malleablewrought ironrails had been the source of a rift between Stephenson and Losh, as Losh had originally expected to supply cast-iron rails from his ironworks, which Stephenson had briefly been a partner in. Stephenson though chose to use an improved iron rail fromJohn Birkinshaw'sBedlington Ironworksinstead.

Notes

editReferences

edit- ^abStrickland, William(1826)."G. Stephenson's Patent Locomotive Engine"(engraving).

- ^Warren, J.G.H. (1970) [1923].A Century of Locomotive Building.David & Charles.p. 24.ISBN0-7153-4378-5.

- ^Thurston, Robert H. (1878).A History of the Growth of the Steam-Engine.

- ^Jones, M.H. (2011).The Brendon Hills Iron Mines and the West Somerset Mineral Railway.Lightmoor Press. p. 16.ISBN9781899889-5-3-2.

- ^"Hackworth spring safety valve"(Image of museum exhibit).National Railway Museum. 1830.

- ^abThurston (1878),p. 187.

- ^abcdLowe, James W. (1975). "George Stephenson".British Steam Locomotive Builders.Guild Publishing. pp. 606–607.ISBN0900404213.

- ^Wood, Nicholas(1825).A Practical Treatise on Rail-roads and Interior Communication in General.London: Knight & Lacey. p. Plate VII.

- ^Bailey (2014),p. 32.

- ^Bailey, Michael R. (2014). "The George Stephenson Types, 1820s".Loco Motion.The History Press. p. 31.ISBN978-0-7524-9101-1.

- ^Stephenson's Killingworth locomotive, 1815,engraving of 1829, unknown author, inThe British Railway Locomotive 1803-1853.HMSO.1958.

- ^Brotchie, Alan W; Jack, Harry (2007).Early Railways of West Fife.Catrine: Stenlake Publishing. pp. 49–53.ISBN978-1-84033-409-8.

- ^"Troon's icon of industry: the first railway locomotive in Scotland".South Ayrshire History Blog.South Ayrshire Libraries. 16 October 2012.

- ^Thurston (1878),p. 190.

- ^abBailey (2014),p. 35–36.