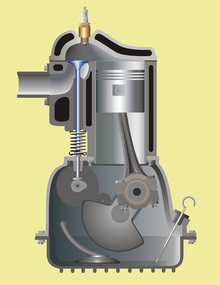

Aflathead engine,also known as asidevalve engine[1][2]orvalve-in-block engine,is aninternal combustion enginewith itspoppet valvescontained within theengine block,instead of in thecylinder head,as in anoverhead valve engine.

Flatheads were widely used internationally by automobile manufacturers from the late 1890s until the mid-1960s[3]but were replaced by more efficient overhead valve andoverhead camshaft engines.They are currently experiencing a revival in low-revvingaero-enginessuch as theD-Motor.[4]

The side-valve design

editThe valve gear comprises a camshaft sited low in the cylinder block which operates thepoppetvalvesviatappetsand short pushrods (or sometimes with no pushrods at all). The flathead system obviates the need for furthervalvetraincomponents such as lengthy pushrods, rocker arms, overhead valves oroverhead camshafts.[5]The sidevalves are typically adjacent, sited on one side of the cylinder(s), though some flatheads employ the less common"crossflow""T-head"variant. In a T-head engine, the exhaust gases leave on the opposite side of the cylinder from the intake valve.

The sidevalve engine's combustion chamber is not above the piston (as in an OHV (overhead valve) engine) but to the side, above the valves. The spark plug may be sited over the piston (as in an OHV engine) or above the valves; but aircraft designs withtwo plugs per cylindermay use either or both positions.[6]

"Pop-up pistons" may be used with compatible heads to increase compression ratio and improve the combustion chamber's shape to preventknocking.[7]"Pop-up" pistons are so called because, attop dead centre,they protrude above the top of the cylinder block.

Advantages

editThe advantages of a sidevalve engine include: simplicity, reliability, low part count, low cost, low weight, compactness, responsive low-speed power, low mechanical engine noise, and insensitivity to low-octane fuel. The absence of a complicated valvetrain allows a compact engine that is cheap to manufacture, since the cylinder head may be little more than a simple metal casting. These advantages explain why side valve engines were used forpassenger carsfor many years, whileOHVdesigns came to be specified only for high-performance applications such asaircraft,luxury cars,sports cars,and somemotorcycles.[citation needed]

At top dead centre, the piston gets very close to the flat portion of the cylinder head above, and the resultantsquishturbulenceproduces excellent fuel/air mi xing. A feature of the sidevalve design (particularly beneficial for an aero-engine) is that if a valve should seize in its guide and remain partially open, the piston would not be damaged, and the engine would continue operating safely on its other cylinders.[citation needed]

Disadvantages

editThe main disadvantages of a sidevalve engine are poor gas flow, poor combustion chamber shape, and low compression ratio, all of which result in a low-revving engine with low power output[8]and low efficiency.[9]Because sidevalve engines do not burn the fuel efficiently, they suffer from high hydrocarbon emissions.[10]

Sidevalve engines can only be used for engines operating on theOtto principle.The combustion chamber shape is unsuitable forDiesel engines,[11]which require a highcompression ratioforignitionto occur.

In a sidevalve engine, intake and exhaust gases follow a circuitous route, with low volumetric efficiency, or "poor breathing", not least because the exhaust gases interfere with the incoming charge. Because the exhaust follows a lengthy path to leave the engine, there is a tendency for the engine tooverheat.(Note: this is true for V-type flathead engines but less of an issue for inline engines which typically have the intake and exhaust ports on the same side of the engine block.) Although a sidevalve engine can safely operate at high speed, itsvolumetric efficiencyswiftly deteriorates, so that high power outputs are not feasible at speed. High volumetric efficiency was less important for early cars because their engines rarely sustained extended high speeds, but designers seeking higher power outputs had to abandon the sidevalve. A compromise used by theWillys Jeep,Rover,Land Rover,andRolls-Roycein the 1950s was the"F-head"(or "intake-over-exhaust" valving), which has one sidevalve and one overhead valve per cylinder.[12]

The flathead's elongated combustion chamber is prone topreignition(or "knocking" ) if compression ratio is increased, but improvements such aslaser ignitionor microwave enhanced ignition might help prevent knocking.[13]Turbulence grooves may increaseswirlinside the combustion chamber, thus increasing torque, especially at low rpm. Better mi xing of the fuel/air charge improves combustion and helps to prevent knocking.[14][15][16][17]

An advance in flathead technology resulted from experimentation in the 1920s bySir Harry Ricardo,who improved their efficiency after studying the gas-flow characteristics of sidevalve engines.[18][9][clarification needed]

The difficulty in designing a high-compression-ratio flathead means that most tend to be spark-ignition designs, and flathead diesels are virtually unknown.

History and applications

editThe sidevalve arrangement was especially common in the United States and used for motor vehicle engines, even for engines with high specific power output.[11]Sidevalve designs are still common for manysmallsingle-cylinderortwin-cylinderengines, such aslawnmowers,rotavators,two-wheel tractorsand otherbasic farm machinery.[citation needed]

Flathead cars

editMulticylinder flathead engines were used for cars such as theFord Model TandFord Model A,theFord flathead V8 engineand theFord Sidevalve engine.CadillacproducedV-16 flathead enginesfor theirSeries 90 luxury carsfrom 1938 to 1940.[19]Packardproduced flathead inline 8-cylinder engines until 1954. Also in the BritishMorris Eight,andMorris Minorseries I.

AfterWWII,flathead designs began to be superseded by OHV (overhead valve) designs. Flatheads were no longer common incars,but they continued in more rudimentary vehicles such asoff-roadmilitary Jeeps.In UScustom carandhot rodcircles, restored examples of early Ford flathead V8s are still seen.[1][20]

Flathead aero-engines

editThe simplicity, lightness, compactness and reliability might seem ideal for anaero-engine,but because of their low efficiency, early flathead engines were deemed unsuitable. Two notable exceptions were the AmericanAeronca E-107opposed twinaero engineof 1930 and theContinental A40flat four of 1931, which became one of the most popular light aircraft engines of the 1930s. Two modern flatheads are the BelgianD-Motorflat-foursandflat-sixes.[21]These are extremelyoversquareand compact aero-engines with direct drive to a propeller.[22][23]

Flathead motorcycles

editFlathead designs have been used on a number of early pre-war motorcycles, in particular US V-twins such asHarley-DavidsonandIndian,some British singles,BMWflat twinsand Russian copies thereof.[24]TheCleveland Motorcycle Manufacturing Companyproduced a T-head four-cylinder in-line motorcycle engine in the 1920s.

-

1915 Cadillac flathead engine block

-

Harley-Davidson flathead

-

Indian Chief Black Hawk

-

BMW R12

-

Cleveland Model 4-45

See also

editNotes

edit- ^abAmerican Rodder,6/94, pp.45 & 93.

- ^(As the cylinder cross-section has the shape of an inverted L, other names such as "L-block" or "L-head" are also used)

- ^"What Was the Final Year for a New Flathead-Powered American Car?".20 December 2018.

- ^"D-Motor image".Archived fromthe originalon 25 February 2018.Retrieved29 April2018.

- ^An exception is theIndianwhich employs both rocker arms and pushrods to transmit motion from the cam lobes to the valve stems.

- ^The D-motor flathead aero-engines have both spark pugs above the valves.

- ^Davis, Marlan (29 September 2006)."Ford Flathead V8 – The Flathead Guide of Death".Hotrod.Hot Rod Magazine. Combustion Chamber.Retrieved8 April2014.

Trying to gain back compression ratio by using popup pistons may improve airflow provided proper attention is paid to the transfer area and overall piston-to-combustion chamber interface. The best balance has been the subject of debate for over 60 years. Currently the most popular approach is running a big popup piston, but with a scallop on the side adjacent to the valves to keep the transfer area clear between the valves and the cylinder bore. Recommended bottom-line street-gas-friendly compression ratios are between 7.5–8:1 on naturally aspirated engines and 6.5–7.0:1 with a blower.

- ^"A critique of the flathead or side valve engine".13 July 2012.Retrieved22 August2015.

- ^abH. Kremser (author): Der Aufbau schnellaufender Verbrennungskraftmaschinen, in Hans List (ed): Die Verbrennungskraftmaschine, volume 11, Springer, Wien 1942,ISBN978-3-7091-9755-4,p. 50

- ^Richard van Basshuysen, Fred Schäfer: Handbuch Verbrennungsmotor. 8. Auflage, Springer, Wiesbaden 2017,ISBN978-3-658-10901-1,Chapter 10, p. 534

- ^abAnton Pischinger (author): Die Steuerung der Verbrennungskraftmaschinen, in Hans List (ed): Die Verbrennungskraftmaschine, volume 9, Springer, Wien 1948,ISBN978-3-211-80075-1,p. 14

- ^Road and Track,some time in the 1960s

- ^Ikeda, Yuji; Nishiyama, Atsushi; Kaneko, Masashi (5–8 January 2009).Microwave Enhanced Ignition Process for Fuel Mixture at Elevated Pressure of 1MPa(PDF).47th AIAA Aerospace Sciences Meeting Including The New Horizons Forum and Aerospace Exposition. American Institute of Aeronautics and Astronautics. p. 1. Archived fromthe original(PDF)on 25 July 2014.Retrieved3 July2014.

With plasma-enhanced combustion, a large flame kernel formed and the flame propagation speed increased. In the single-cylinder engine, the combustion stability improved and the microwave-enhanced ignition increased the lean limit from 19.3 to 24.1.

- ^Graeber, Charles (23 September 2004)."Obsession: Mr. Singh's Search for the Holy Grail".Popular Science.Bonnier.Retrieved3 July2014.

In November 2002 Singh actually received one such permission from a manufacturer to test his modification on its engines. The manufacturer was Briggs and Stratton, and the engines were two 149cc side valves.

- ^Pirangute, V. G.; N.V.Marathe (14 January 2002).Full throttle performance(PDF)(Technical report). ARAI. PUS/2407/Garuda/52(d). Archived fromthe original(PDF)on 7 October 2016.The test report reveals that fuel consumption and temperatures decreased at low engine speed while torque increased.

- ^amrelweekil (14 September 2009)."Engine modify by Somender Singh".YouTube.Grooved flathead at 1:31–1:38.Archivedfrom the original on 12 December 2021.Retrieved9 April2014.

- ^PatentUS 6237579Somender Singh: "Design to improve turbulence in combustion chambers"

- ^The internal-combustion engineby Harry Ralph Ricardo, Blackie and Son Limited.

- ^LaChance, David (February 2007)."Reignmaker – 1939 Cadillac Series 39-90".Hemmings Motor News.American City Business Journals.Retrieved17 November2015.

Mechanically, the Series 90 cars shared the advances of the Series 75. The V-8 car's three-speed manual transmission was deemed up to the task of handing the torque of the V-16, in part because the larger engine delivered its impulses so smoothly.

- ^Street Rodder,1/85, p.72.

- ^Although very small and compact, the D-Motor flat-six displaces nearly 4 litres.

- ^"Kapelstraat 198 8540 Deerlijk – Recent information".D-motor.eu. Archived fromthe originalon March 28, 2012.RetrievedDecember 6,2011.

- ^Tacke, Willi; Marino Boric; et al:World Directory of Light Aviation 2015-16,pages 256-257. Flying Pages Europe SARL, 2015.ISSN1368-485X

- ^For example, some Dnepr and Ural used flathead designs that BMW had licensed to the Soviets.