Vitreous enamel

Vitreous enamel,also calledporcelain enamel,is a material made byfusingpowderedglassto a substrate by firing, usually between 750 and 850 °C (1,380 and 1,560 °F). The powder melts, flows, and then hardens to a smooth, durablevitreouscoating. The wordvitreouscomes from the Latinvitreus,meaning "glassy".

Enamel can be used onmetal,glass,ceramics,stone, or any material that will withstand the fusing temperature. In technical terms fired enamelware is an integrated layered composite of glass and another material (or more glass). The term "enamel" is most often restricted to work on metal, which is the subject of this article. Essentially the same technique used with other bases is known by different terms: on glass asenamelled glass,or "painted glass", and on pottery it is calledoverglaze decoration,"overglaze enamels" or "enamelling". The craft is called "enamelling",the artists" enamellers "and the objects produced can be called" enamels ".

Enamelling is an old and widely adopted technology, for most of its history mainly used injewelleryanddecorative art.Since the 18th century, enamels have also been applied to many metal consumer objects, such as somecooking vessels,steel sinks, andcast-ironbathtubs. It has also been used on someappliances,such asdishwashers,laundry machines,andrefrigerators,and on marker boards andsignage.

The term "enamel" has also sometimes been applied to industrial materials other than vitreous enamel, such asenamel paintand the polymers coatingenameled wire;these actually are very different inmaterials scienceterms.

The wordenamelcomes from theOld High Germanwordsmelzan(tosmelt) via theOld Frenchesmail,[1]or from a Latin wordsmaltum,first found in a 9th-centuryLife of Leo IV.[2]Used as a noun, "an enamel" is usually a small decorative object coated with enamel. "Enamelled" and "enamelling" are the preferred spellings inBritish English,while "enameled" and "enameling" are preferred inAmerican English.

History

[edit]

Ancient

[edit]The earliest enamel all used the cloisonné technique, placing the enamel within small cells with gold walls. This had been used as a technique to hold pieces of stone and gems tightly in place since the 3rd millennium BC, for example inMesopotamia,and then Egypt. Enamel seems likely to have developed as a cheaper method of achieving similar results.[3]

The earliest undisputed objects known to use enamel are a group ofMycenaeanrings fromCyprus,dated to the 13th century BC.[3]Although Egyptian pieces, including jewellery from theTomb of Tutankhamunof c. 1325 BC, are frequently described as using "enamel", many scholars doubt the glass paste was sufficiently melted to be properly so described, and use terms such as "glass-paste". It seems possible that in Egyptian conditions the melting point of the glass and gold were too close to make enamel a viable technique. Nonetheless, there appear to be a few actual examples of enamel, perhaps from theThird Intermediate Period of Egypt(beginning 1070 BC) on.[4]But it remained rare in both Egypt and Greece.

The technique appears in theKobanculture of the northern and centralCaucasus,and was perhaps carried by theSarmatiansto the ancient Celts.[3]Red enamel is used in 26 places on theBattersea Shield(c.350–50 BC), probably as an imitation of the red Mediterraneancoral,which is used on theWitham Shield(400–300 BC).Pliny the Eldermentions the Celts' use of the technique on metal, which the Romans in his day hardly knew. TheStaffordshire Moorlands Panis a 2nd-century AD souvenir ofHadrian's Wall,made for the Roman military market, which has swirling enamel decoration in a Celtic style. In Britain, probably through preserved Celtic craft skills, enamel survived until thehanging bowlsof earlyAnglo-Saxon art.

A problem that adds to the uncertainty over early enamel is artefacts (typically excavated) that appear to have been prepared for enamel, but have now lost whatever filled the cloisons or backing to achamplevépiece.[3]This occurs in several different regions, from ancient Egypt to Anglo-Saxon England. Once enamel becomes more common, as in medieval Europe after about 1000, the assumption that enamel was originally used becomes safer.

Medieval and Renaissance Europe

[edit]

In European art history, enamel was at its most important in theMiddle Ages,beginning with the Late Romans and then theByzantine,who began to usecloisonnéenamel in imitation of cloisonné inlays of precious stones. TheByzantine enamelstyle was widely adopted by the peoples ofMigration Periodnorthern Europe. The Byzantines then began to use cloisonné more freely to create images; this was also copied in Western Europe. InKievan Rusafinift enameltechnique was developed.[5][6]

Mosan metalworkoften included enamel plaques of the highest quality inreliquariesand other large works ofgoldsmithing.Limoges enamelwas made inLimoges,France, the most famous centre of vitreous enamel production in Western Europe, though Spain also made a good deal. Limoges became famous for champlevé enamels from the 12th century onwards, producing on a large scale, and then (after a period of reduced production) from the 15th century retained its lead by switching to painted enamel on flat metal plaques. Thechamplevétechnique was considerably easier and very widely practiced in theRomanesqueperiod. InGothic artthe finest work is inbasse-tailleandronde-bossetechniques, but cheaper champlevé works continued to be produced in large numbers for a wider market.

Painted enamel remained in fashion for over a century, and in France developed into a sophisticated Renaissance and theManneriststyle, seen on objects such as large display dishes, ewers,inkwellsand in small portraits. After it fell from fashion it continued as a medium forportrait miniatures,spreading to England and other countries. This continued until the early 19th century.

A Russian school developed, which used the technique on other objects, as in the Renaissance, and for relatively cheap religious pieces such as crosses and small icons.

China

[edit]

From either Byzantium or the Islamic world, the cloisonné technique reached China in the 13–14th centuries. The first written reference to cloisonné is in a book from 1388, where it is called "Dashi ('Muslim') ware".[7]No Chinese pieces that are clearly from the 14th century are known; the earliest datable pieces are from the reign of theXuande Emperor(1425–1435), which, since they show a full use of Chinese styles, suggest considerable experience in the technique.

Cloisonné remained very popular in China until the 19th century and is still produced today. The most elaborate and most highly valued Chinese pieces are from the earlyMing dynasty,especially the reigns of the Xuande Emperor andJingtai Emperor(1450–1457), although 19th century or modern pieces are far more common.[7]

Japan

[edit]

Japanese artists did not make three-dimensional enamelled objects until the 1830s but, once the technique took hold based on analysis of Chinese objects, it developed very rapidly, reaching a peak in theMeijiandTaishōeras (late 19th/early 20th century).[8]Enamel had been used as decoration for metalwork since about 1600,[9][8]and Japanese cloisonné was already exported to Europe before the start of the Meiji era in 1868.[8]Cloisonné is known in Japan asshippo,literally "seven treasures".[10]This refers to richly coloured substances mentioned in Buddhist texts.[11]The term was initially used for colourful objects imported from China. According to legend, in the 1830sKaji Tsunekichibroke open a Chinese enamel object to examine it, then trained many artists, starting off Japan's own enamel industry.[11][9]

Early Japanese enamels were cloudy and opaque, with relatively clumsy shapes. This changed rapidly from 1870 onwards.[8]The Nagoya cloisonné company (Nagoya shippo kaishaexisted from 1871 to 1884, to sell the output of many small workshops and help them improve their work.[8]In 1874, the government created theKiriu kosho kaishacompany to sponsor the creation of a wide range of decorative arts at international exhibitions. This was part of a programme to promote Japan as a modern, industrial nation.[8]

Gottfried Wagenerwas a German scientist brought in by the government to advise Japanese industry and improve production processes. Along withNamikawa Yasuyukihe developed a transparent black enamel which was used for backgrounds. Translucent enamels in various other colours followed during this period.[8]Along withTsukamoto Kaisuke,Wagener transformed the firing processes used by Japanese workshops, improving the quality of finishes and extending the variety of colours.[8]Kawade Shibatarōintroduced a variety of techniques, includingnagare-gusuri(drip-glaze) which produces a rainbow-coloured glaze anduchidashi(repoussé) technique, in which the metal foundation is hammered outwards to create areliefeffect.[12]Together withHattori Tadasaburōhe developed themoriage( "piling up" ) technique which places layers of enamel upon each other to create a three-dimensional effect.[13]Namikawa Sōsukedeveloped a pictorial style that imitated paintings. He is known forshosen(minimised wires) andmusen(wireless cloisonné): techniques developed with Wagener in which the wirecloisonsare minimised or burned away completely with acid.[14][9]This contrasts with the Chinese style which used thick metalcloisons.[8]Ando Jubeiintroduced theshōtai-jippō(plique-à-jour) technique which burns away the metal substrate to leave translucent enamel, producing an effect resemblingstained glass.[15]TheAndo Cloisonné Companywhich he co-founded is one of the few makers from this era still active.[8]Distinctively Japanese designs, in which flowers, birds and insects were used as themes, became popular. Designs also increasingly used areas of blank space.[9]With the greater subtlety these techniques allowed, Japanese enamels were regarded as unequalled in the world[16]and won many awards at national and international exhibitions.[14][17]

India and Islamic world

[edit]

Enamel was established in theMughal Empireby around 1600 for decorating gold and silver objects, and became a distinctive feature of Mughal jewellery. The Mughal court was known to employmīnākār(enamelers).[18]These craftsmen reached a peak of during the reign ofShah Jahanin the mid-17th century. Transparent enamels were popular during this time.[18]Both cloissoné and champlevé were produced in Mughal, with champlevé used for the finest pieces.[18]Modern industrial production began inCalcuttain 1921, with theBengal Enamel WorksLimited.

Enamel was used inIranfor colouring and ornamenting the surface of metals by fusing over it brilliant colours that are decorated in an intricate design calledMeenakari.The French travellerJean Chardin,who toured Iran during theSafavidperiod, made a reference to an enamel work ofIsfahan,which comprised a pattern of birds and animals on a floral background in light blue, green, yellow and red. Gold has been used traditionally for Meenakari jewellery as it holds the enamel better, lasts longer and its lustre brings out the colours of the enamels.Silver,a later introduction, is used for artifacts like boxes, bowls, spoons, and art pieces.Copperbegan to be used for handicraft products after the Gold Control Act, was enforced in India which compelled the Meenakars to look for an alternative material. Initially, the work of Meenakari often went unnoticed as this art was traditionally used on the back of pieces ofkundanor gem-studded jewellery, allowing pieces to be reversible.[19]

Modern

[edit]

More recently, the bright, jewel-like colours have made enamel popular with jewellery designers, including theArt Nouveaujewellers, for designers ofbibelotssuch as the eggs ofPeter Carl Fabergéand the enameled copper boxes of the Battersea enamellers,[20]and for artists such asGeorge Stubbsand other painters ofportrait miniatures.

A resurgence in enamel-based art took place near the end of the 20th century in theSoviet Union,led by artists likeAlexei MaximovandLeonid Efros.InAustralia,abstract artistBernard Heslingbrought the style into prominence with his variously sized steel plates.[21]

Enamel was first applied commercially to sheet iron and steel in Austria and Germany in about 1850.[22]: 5 Industrialization increased as the purity of raw materials increased and costs decreased. The wet application process started with the discovery of the use of clay to suspendfritin water. Developments that followed during the 20th century include enamelling-grade steel, cleaned-only surface preparation, automation, and ongoing improvements in efficiency, performance, and quality.[22]: 5

Properties

[edit]

Vitreous enamel can be applied to most metals. Most modern industrial enamel is applied to steel in which the carbon content is controlled to prevent unwanted reactions at the firing temperatures. Enamel can also be applied to gold, silver, copper,aluminium,[23]stainless steel,[24]andcast iron.[25]

Vitreous enamel has many useful properties: it is smooth, hard, chemically resistant, durable, scratch resistant (5–6 on theMohs scale), has long-lasting colour fastness, is easy to clean, and cannot burn. Enamel is glass, not paint, so it does not fade underultraviolet light.[26]A disadvantage of enamel is a tendency to crack or shatter when the substrate is stressed or bent, but modern enamels are relatively chip- and impact-resistant because of good thickness control and coefficients ofthermal expansionwell-matched to the metal.[citation needed]

The Buick automobile company was founded byDavid Dunbar Buickwith wealth earned by his development of improved enamelling processes, c. 1887, for sheet steel and cast iron. Such enameled ferrous material had, and still has, many applications: early 20th century and some modernadvertisingsigns, interiorovenwalls,cooking pots,housing and interior walls of majorkitchen appliances,housing and drums of clothes washers and dryers, sinks andcast ironbathtubs,farmstorage silos,and processing equipment such aschemical reactorsand pharmaceutical process tanks. Structures such asfilling stations,bus stationsandLustron Houseshad walls, ceilings and structural elements made of enamelled steel.[citation needed]

One of the most widespread modern uses of enamel is in the production of quality chalk-boards and marker-boards (typically called 'blackboards' or 'whiteboards') where the resistance of enamel to wear and chemicals ensures that 'ghosting', or unerasable marks, do not occur, as happens with polymer boards. Since standard enamelling steel is magnetically attractive, it may also be used for magnet boards. Some new developments in the last ten years include enamel/non-stick hybrid coatings, sol-gel functional top-coats for enamels, enamels with a metallic appearance, and easy-to-clean enamels.[27]

The key ingredient of vitreous enamel is finely ground glass calledfrit.Frit for enamelling steel is typically an alkali borosilicate glass with a thermal expansion and glass temperature suitable for coating steel. Raw materials are smelted together between 2,100 and 2,650 °F (1,150 and 1,450 °C) into a liquid glass that is directed out of the furnace and thermal shocked with either water or steel rollers into frit.[28]

Colour in enamel is obtained by the addition of various minerals, often metal oxidescobalt,praseodymium,iron,orneodymium.The latter creates delicate shades ranging from pure violet through wine-red and warm grey. Enamel can be transparent, opaque or opalescent (translucent). Different enamel colours can be mixed to make a new colour, in the manner of paint.

There are various types of frit, which may be applied in sequence. A ground coat is applied first; it usually contains smelted-in transition metal oxides such as cobalt, nickel, copper, manganese, and iron that facilitate adhesion to the metal. Next, clear and semi-opaque frits that contain material for producing colours are applied.

-

View into a glass-lined chemical reactor

-

Turb-mixer in a glass-lined chemical reactor

Techniques of artistic enameling

[edit]

The three main historical techniques for enamelling metal are:

- Cloisonné,French for "cell", where thin wires are applied to form raised barriers, which contain different areas of (subsequently applied) enamel. Widely practiced in Europe, the Middle East and East Asia.[29]

- Champlevé,French for "raised field", where the surface is carved out to form pits in which enamel is fired, leaving the original metal exposed; the RomanesqueStavelot Triptychis an example.[30]

- Painted enamel, a design in enamel is painted onto a smooth metal surface.Limoges enamelis the best known type of painted enamel, using this from the 16th century onwards.[31]Most traditional painting on glass, and some on ceramics, uses what is technically enamel, but is often described by terms such as "painted in enamels", reserving "painted enamel" and "enamel" as a term for the whole object for works with a metal base.[32]

Variants, and less common techniques are:

- Basse-taille,from the French word meaning "low-cut". The surface of the metal is decorated with a low relief design which can be seen through translucent and transparent enamels. The 14th centuryRoyal Gold Cupis an outstanding example.[33]

- Plique-à-jour,French for "open to daylight" where the enamel is applied in cells, similar to cloisonné, but with no backing, so light can shine through the transparent or translucent enamel. It has a stained-glass like appearance; theMérode Cupis the surviving medieval example.[34]

- Ronde bosse,French for "in the round", also known as "encrusted enamel". A 3D type of enamelling where a sculptural form or wire framework is completely or partly enamelled, as in the 15th centuryHoly Thorn Reliquary.[35]

- Grisaille,version of painted enamel, French term meaning "in grey", where a dark, often blue or black background is applied, then a palescent (translucent) enamel is painted on top, building up designs in a monochrome gradient, paler as the thickness of the layer of light colour increases.[36]

- En résille(Émail en résille sur verre,French for 'enamel in a network on glass') where enamelled metal is suspended in glass. The technique was briefly popular in seventeenth-century France and was re-discovered byMargret Craverin 1953. Craver spent 13 years re-creating the technique.[37]

Other types:

- Enamelled glass,in which a glass surface is enamelled, and fired to fuse the glasses.

- Stenciling,where a stencil is placed over the work and the powdered enamel is sifted over the top. The stencil is removed before firing, the enamel staying in a pattern, slightly raised.

- Sgraffito,where an unfired layer of enamel is applied over a previously fired layer of enamel of a contrasting colour, and then partly removed with a tool to create the design.

- Serigraph,where a silkscreen is used with 60–70in grade mesh.

- Surrey enamel, a 17th-century type for brass objects such as candlesticks; effectively champlevé.[38]

- Counter-enamelling,not strictly a technique, but a necessary step in many techniques, especially painted enamel on thin plaques; introduced in 15th-century Europe. Enamel is applied to the back of a piece as well – sandwiching the metal – to equalize the rates of expansion under heat, and so create less tension on the glass so it does not crack.[36]

- Safed chalwan,where jewels are set in white enamel

See alsoJapanese shipōyaki techniques.

Industrial enamel application

[edit]

On sheet steel, a ground coat layer is applied to create adhesion. The only surface preparation required for modern ground coats is degreasing of the steel with a mildly alkaline solution. White and coloured second "cover" coats of enamel are applied over the fired ground coat. For electrostatic enamels, the coloured enamel powder can be applied directly over a thin unfired ground coat "base coat" layer that is co-fired with the cover coat in a very efficient two-coat/one-fire process.

The frit in the ground coat contains smelted-in cobalt and/or nickel oxide as well as other transition metal oxides to catalyse the enamel-steel bonding reactions. During firing of the enamel at between 760 and 895 °C (1,400 and 1,643 °F), iron oxide scale first forms on the steel. The molten enamel dissolves the iron oxide and precipitates cobalt andnickel.The iron acts as the anode in an electrogalvanic reaction in which the iron is again oxidised, dissolved by the glass, and oxidised again with the available cobalt and nickel limiting the reaction. Finally, the surface becomes roughened with the glass anchored into the holes.[39]

Building cladding

[edit]Enamel coatings applied to steel panels offer protection to the core material whether cladding road tunnels, underground stations, building superstructures or other applications. It can also be specified as a curtain walling. Qualities of this structural material include:[40]

- Durable

- Withstands extreme temperatures and is non-flammable

- Long lasting UV, climate and corrosion resistance

- Dirt-repellent and graffiti-proof

- Resistant to abrasion and chemicals

- Easy cleaning and maintenance

Gallery

[edit]-

Early 13th century Limogeschasseused to hold holy oils; most werereliquaries.

-

Silver, silver gilt and painted enamel beaker,Burgundian Netherlands,c. 1425–1450,The Cloisters,nyc

-

TheRoyal Gold Cupwithbasse-tailleenamels; weight 1.935 kg,British Museum.Saint Agnesappears to her friends in a vision.

-

Limoges? grisaille paintedStations of the Cross,Notre-Dame-des-Champs, Avranches

-

St.Gregory the Greatin painted Limoges enamel on a copper plaque, by Jacques I Laudin

-

A freehand enameled painting byEinar Hakonarson.In the forest,1989

-

Louis Georgeenamel watch dial

-

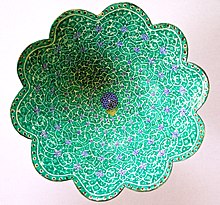

Iranian enamel

See also

[edit]- Fred Uhl Ball(1945–1985) – American enamellist who created the largest known enamel mural

- Oskar Schindler

- Rostovin Russia, with Moscow a centre of the Russian industry

Notes

[edit]- ^Campbell, 6

- ^Chisholm, Hugh,ed. (1911)..Encyclopædia Britannica(11th ed.). Cambridge University Press.

- ^abcdOsborne, 331

- ^Ogden, 166

- ^Наумов, Олег (2019-01-01), "ХУДОЖНЯ ЕМАЛЬ У ХРОНОТОПІ УКРАЇНСЬКОГО МИСТЕЦТВА. Альманах",Культура і Сучасність,vol. 2019(2), pp. 192–197

- ^Мостовщикова, Дар'я Олегівна (2020),"Traditions of painted hot enamel of Europe and the East of the XVIIIth century in contemporary enamel art of Ukraine",Актуальнi питання гуманiтарних наук: Мiжвузiвський збiрник наукових праць молодих вчених Дрогобицького державного педагогiчного унiверситету iменi Iвана Франка,vol. 1(30), pp. 173–180

- ^abSullivan, Michael,The arts of China,4th edn, p. 239, University of California Press, 1999,ISBN0-520-21877-9,ISBN978-0-520-21877-2,Google books

- ^abcdefghijImpey, Oliver; Fairley, Malcolm (2009). "Enamel in Japan". In Williams, Haydn (ed.).Enamels of the world, 1700-2000: the Khalili collections.London: Khalili Family Trust. pp. 149–156.ISBN978-1-874780-17-5.

- ^abcdEarle, Joe (1999).Splendors of Meiji: treasures of imperial Japan: masterpieces from the Khalili Collection.St. Petersburg, Fla.: Broughton International Inc. pp. 252–254.ISBN1874780137.OCLC42476594.

- ^Harada, Jiro (1911)."Japanese Art & Artists of To-day VI. Cloisonné Enamels".The Studio.53:271 – via Internet Archive.

- ^ab"Polished to Perfection".Asian Art Newspaper.5 November 2017.ISSN1475-1372.Retrieved16 July2020.

- ^"Kawade Shibatarō | Imperial Presentation Vase with Maple Branches and Imperial Chrysanthemum Crest (one of a pair)".www.metmuseum.org.Metropolitan Museum of Art.Retrieved16 July2020.

- ^Irvine, Gregory (2013).Japonisme and the rise of the modern art movement: the arts of the Meiji period: the Khalili collection.New York: Thames & Hudson. p. 181.ISBN978-0-500-23913-1.OCLC853452453.

- ^abLeonard, Loryn (2012-06-26)."How It's Made: Japanese Cloisonné".Dallas Museum of Art Uncrated.Retrieved2020-10-16.

- ^"Ashmolean − Eastern Art Online, Yousef Jameel Centre for Islamic and Asian Art".jameelcentre.ashmolean.org.Ashmolean Museum, University of Oxford.Retrieved16 July2020.

- ^"Japanese Art Enamels".The Decorator and Furnisher.21(5): 170. 1893.ISSN2150-6256.JSTOR25582341.

We doubt if any form of the enameller's art can equal the work executed in Japan, which is distinguished by great freedom of design, and the most exquisite gradations of color.

- ^Toyoro Hida, Gregory Irvine, Kana Ooki, Tomoko Hana and Yukari Muro.Namikawa Yasuyuki and Japanese Cloisonné The Allure of Meiji Cloisonné: The Aesthetic of Translucent Black,pp.182-188,The Mainichi Newspapers Co, Ltd,2017

- ^abcMoura Carvalho, Pedro (2009). "Enamel in the Islamic Lands". In Williams, Haydn (ed.).Enamels of the world, 1700-2000: the Khalili collections.London: Khalili Family Trust. pp. 187–196.ISBN978-1-874780-17-5.

- ^"The Art of Minakari".iranreview.org.

- ^"What is Vitreous Enamel?".vea.org.uk.

- ^database and e-research tool for art and design researchers."Bernard Hesling:: biography at:: at Design and Art Australia Online".Daao.org.au.Retrieved2013-12-25.

- ^abAndrews, Andrew Irving,Porcelain enamels: the preparation, application, and properties of enamels,Garrard Press, 1961

- ^Judd, Donald, “Porcelain Enameling Aluminum: An Overview,” Proceedings of the 59th Porcelain Enamel Institute Technical Forum, 45-51 (1997).

- ^Sullivan, J.D. and Nelson, F.W., "Stainless Steel Requires Special Enameling Procedures", Proceedings of the Porcelain Enamel Institute Technical Forum, "150–155 (1970).

- ^Pew, Steve, "The Who, What, Why, Where, and When of Cast Iron Enameling," Advances in Porcelain Enamel Technology, 177–186, (2010).

- ^Fedak, David and Baldwin, Charles, "A Comparison of Enameled and Stainless Steel Surfaces," Proceedings of the 67th Porcelain Enamel Institute Technical Forum, 45-54 (2005).

- ^Gavlenski, Jim and Baldwin, Charles, "Advanced Porcelain Enamel Coatings with Novel Properties," Proceedings of the 69th Porcelain Enamel Institute Technical Forum, 53-58, (2007).

- ^Andrews, A.I. Porcelain Enamels, The Garrard Press: Champaign, IL, 1961 p. 321-2.

- ^Campbell, 6, 10-17

- ^Campbell, 7, 17-32

- ^Campbell, 7

- ^British Museumcollection database, "Scope note" for the term "enamelled"; other sources use different categories.

- ^Campbell, 7, 33-41

- ^Campbell, 38-42

- ^Campbell, 7, 42

- ^abLucie-Smith, 83

- ^"Craft: Jewelry: Brooch".Luce Foundation Center for American Art.Smithsonian American Art Museum. Archived fromthe originalon 13 July 2009.Retrieved29 March2013.

- ^Lucie-Smith, 84

- ^Feldman, Sid and Baldwin, Charles, "Surface Tension and Fusion Properties of Porcelain Enamels," Proceedings of the 69th Porcelain Enamel Institute Technical Forum, 1-10 (2008)

- ^Vitreous and porcelain enamels — Characteristics of enamel coatings applied to steel panels intended for architecture.Standards Policy and Strategy Committee. 2008.ISBN978-0-580-72284-4.

References

[edit]- Campbell, Marian.An Introduction to Medieval Enamels,1983,HMSOforV&A Museum,ISBN0-11-290385-1

- Lucie-Smith, Edward,The Thames & Hudson Dictionary of Art Terms,2003 (2nd edn), Thames & Hudson, World of Art series,ISBN0500203652

- Ogden, Jack, "Metal", inAncient Egyptian Materials and Technology,eds. Paul T. Nicholson, Ian Shaw, 2000, Cambridge University Press,ISBN0521452570,9780521452571,google books

- Osborne, Harold (ed),The Oxford Companion to the Decorative Arts,1975, OUP,ISBN0198661134

Further reading

[edit]- "Collection Highlights: Art in the Islamic World". Beaker. Smithsonian Institution: 2013.

- Dimand, M. S. "An Enameled-Glass Bottle of the Mamluk Period". Metropolitan Museum of Art.

- Maryon, Herbert(1971)."Enamelling".Metalwork and Enamelling(5th ed.). New York: Dover.ISBN0-486-22702-2.

- Papadopoulous, Kiko. "Venetian Eastern Trade: 11th to 14th Centuries" 20 January 2012.

External links

[edit]- Enamels on jewelry– historical

- Enameling Articles and Tutorials at The Ganoksin Project

- CIDAE Center of Information and Difusion of the Art of Enamelling (ES)

- Society of Dutch Enamellers (NL)

- The Enamelist Society (US)

- Guild of Enamellers, UK

- International Enamellers Institute

- Vitreous Enamel Association (UK)