Aluminium bronze

This articleneeds additional citations forverification.(July 2010) |

Aluminium bronzeis a type ofbronzein whichaluminiumis the mainalloyingmetaladded tocopper,in contrast to standard bronze (copper andtin) orbrass(copper andzinc). A variety of aluminium bronzes of differing compositions have found industrial use, with most ranging from 5% to 11% aluminium by weight, the remaining mass being copper; other alloying agents such asiron,nickel,manganese,andsiliconare also sometimes added to aluminium bronzes.

Compositions[edit]

The following table lists the most common standard aluminium bronze wrought alloy compositions, by ISO 428 designations. The percentages show the proportional composition of the alloy by weight. Copper is the remainder by weight and is not listed:

| Alloy | Aluminium | Iron | Nickel | Manganese | Zinc | Arsenic |

|---|---|---|---|---|---|---|

| CuAl5 | 4.0–6.5% | 0.5% max. | 0.8% max. | 0.5% max. | 0.5% max. | 0.4% max. |

| CuAl8 | 7.0–9.0% | 0.5% max. | 0.8% max. | 0.5% max. | 0.5% max. | |

| CuAl8Fe3 | 6.5–8.5% | 1.5–3.5% | 1.0% max. | 0.8% max. | 0.5% max. | |

| CuAl9Mn2 | 8.0–10.0% | 1.5% max. | 0.8% max. | 1.5–3.0% | 0.5% max. | |

| CuAl10Fe3 | 8.5–11.0% | 2.0–4.0% | 1.0% max. | 2.0% max. | 0.5% max. | |

| CuAl10Fe5Ni5 | 8.5–11.5% | 2.0–6.0% | 4.0–6.0% | 2.0% max. | 0.5% max. |

Material properties[edit]

Aluminium bronzes are most valued for their higher strength andcorrosionresistance as compared to other bronze alloys. These alloys aretarnish-resistant and show low rates of corrosion inatmosphericconditions, lowoxidationrates at high temperatures, and low reactivity withsulfurouscompounds and otherexhaustproducts ofcombustion.They are also resistant to corrosion insea water.Aluminium bronzes' resistance to corrosion results from the aluminium in the alloys, which reacts with atmosphericoxygento form a thin, tough surface layer ofalumina(aluminium oxide) which acts as a barrier to corrosion of the copper-rich alloy. The addition oftincan improve corrosion resistance.[1]

Another notable property of aluminium bronzes are theirbiostaticeffects. The copper component of the alloy prevents colonization by marine organisms includingalgae,lichens,barnacles,andmussels,and therefore can be preferable tostainless steelor other non-cupric alloys in applications where such colonization would be unwanted.

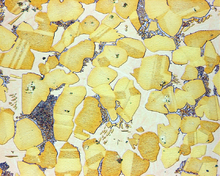

Aluminium bronzes tend to have a golden color.

Applications[edit]

Aluminium bronzes are most commonly used in applications where their resistance to corrosion makes them preferable to other engineering materials. These applications includeplain bearingsandlanding gearcomponents onaircraft,guitar strings,valve components,enginecomponents (especially for seagoing ships), underwater fastenings innaval architecture,and shippropellers.[2]Aluminium bronze is also used to fulfil theATEX directivefor Zones 1, 2, 21, and 22. The attractive gold-toned coloration of aluminium bronzes has also led to their use injewellery.

Aluminium bronzes are in the highest demand from the following industries and areas:

- General sea water-related service

- Water supply

- Oilandpetrochemicalindustries (i.e.tools for use in non-sparking environments)

- Specialised anti-corrosive applications

- Certain structural retrofit building applications

Aluminium bronze can beweldedusing theMIGwelding technique with an aluminium bronze core and pureargongas.

Aluminium bronze is used to replace gold for the casting ofdental crowns.The alloys used are chemically inert and have the appearance of gold.

The Doehler Die Casting Co. of Toledo, Ohio were known for the production of Brastil, a high tensile corrosion resistant bronze alloy.[3][4]

Italy pioneered the use for coinage of an aluminium-bronze alloy calledbronzital(literally "Italian bronze" ) in its 5- and 10-centesimi from 1939. Its alloy was finalized in 1967 to 92% copper, 6% aluminium, and 2% nickel,[5]and was since used in the 20, 200 and 500Italian Liracoins until 2001. Bronzital has since been used for theAustralianandNew Zealand1- and 2-dollar coins, the pre-2009Mexican20- and 50-centavo coins, the inner cores of the bi-metallic Mexican 1-, 2- and 5-peso coins, the pre-2017Philippine 10-peso coin,theCanadian 2 dollar coin(a.k.a. the 'toonie'), and the outer rings of the Mexican 10-, 20-, 50- and 100-peso coins.

Nordic Gold,composed of 89% copper, 5% aluminium, 5% zinc, and 1% tin, is a more recently developed aluminium-bronze alloy for coinage. It was first used for the Swedish10-kronorcoin in 1991, and became widespread after the introduction of Nordic gold 10, 20 and 50-centEuro coinsin 2002.

References[edit]

- ^"Emerald | Anti-Corrosion Methods and Materials | Effect of tin addition on the corrosion resistance of aluminium bronze".Archived fromthe originalon 2014-02-02.Retrieved2011-01-11.

- ^"Typical Alloys Used - Accurate Specialties Inc".Accurate Specialties Inc.Retrieved2018-08-28.

- ^"Doehler-Jarvis Company Collection, MSS-202".

- ^Woldman’s Engineering Alloys, 9th Edition 1936, American Society for Metals,ISBN978-0-87170-691-1

- ^"20 Lire, Italy".en.numista.com.

External links[edit]

Media related toAluminium bronzeat Wikimedia Commons

Media related toAluminium bronzeat Wikimedia Commons- Copper Development Association."Publication Number 80: Aluminium Bronze Alloys Corrosion Resistance Guide", PDFArchived2016-04-05 at theWayback Machine.Retrieved April 9, 2014.

- Copper Development Association."Publication Number 82: Aluminium Bronze Alloys Technical Data".Retrieved April 9, 2014