Carburetor icing

This article includes a list of generalreferences,butit lacks sufficient correspondinginline citations.(February 2023) |

Inengine design,carburetor icingis anicingcondition which can affectcarburetorsunder certainatmospheric conditions.The problem is most notable in aviation engines using float-type carburetors.

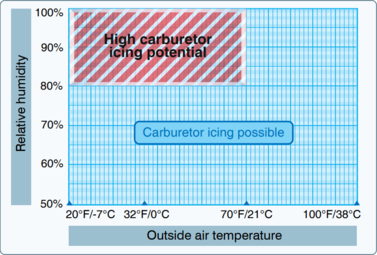

Carburetor icing is caused by the temperature drop in the carburetor, as an effect of fuelvaporization,and the temperature drop associated with the pressure drop in theventuri.[2]If the temperature drops below freezing,water vaporwill freeze onto thethrottlevalve, and other internal surfaces of the carburetor. The venturi effect can reduce the air temperature by 39 K; 39 °C (70 °F). In other words, air at an outside temperature of 38 °C (100 °F), can drop to −1 °C (30 °F) in the carburetor. Carburetor icing most often occurs when the outside air temperature is below 21 °C (70 °F) and therelative humidityis above 80 percent.[1]The risk of carburettor icing is significantly increased at partial power settings (such as when power is reduced during descent), due to the cooling effect of the partly-closed throttle.[2]

The high ambient temperature at which it can occur often causes aircraft pilots to overlook the possibility of carb icing. Theicewill form on the surfaces of the carburetor throat, further restricting it. This may increase theventuri effectinitially, but eventually restricts airflow, perhaps even causing a complete blockage of air to the carburetor. The engine begins to run more rich as ice formation increases. Without intervention (such as carburetor heating or manually adjusting theair–fuel ratio) this can continue until the air–fuel ratio is outside the correct range for proper operation of the engine. Icing may also cause jamming of the mechanical parts of the carburetor, such as the throttle, typically abutterfly valve.

While it can affect any carburetor, carburetor icing is of particular concern inpiston-poweredaircraft,especially small, single-engine, light aircraft. Aircraft powered by carburetedenginesare equipped withcarburetor heatingsystems to counter icing. In road vehicles, carburetor icing can occasionally be a nuisance, although some engine designs are more susceptible to it than others. Theinlet manifoldand parts of the carburetor often have warm water from thecooling systemorexhaust gascirculating through them to combat this problem.Air-cooled enginesmay be more prone to icing, due to the absence of warmcoolantcirculating through the engine.

See also[edit]

References[edit]

- ^ab"Chapter 7: Aircraft Systems".Pilot's Handbook of Aeronautical Knowledge, FAA-H-8083-25B(PDF).US Dept. of Transportation, FAA. 2016. pp. 7-8–7-10. Archived fromthe original(PDF)on 2022-12-06.Retrieved2023-02-25.

As mentioned earlier, one disadvantage of the float-type carburetor is its icing tendency.

- ^abVisual Flight Rules Guide.Civil Aviation Safety Authority (Version 7.2 ed.). Canberra: Australian Government. 2023. pp. 96–97.