Mercury-arc valve

Amercury-arc valveormercury-vapor rectifieror (UK)mercury-arc rectifier[1][2]is a type of electricalrectifierused for converting high-voltageor high-currentalternating current(AC) intodirect current(DC). It is a type ofcold cathodegas-filled tube,but is unusual in that the cathode, instead of being solid, is made from a pool of liquidmercuryand is therefore self-restoring. As a result mercury-arc valves, when used as intended, are far more robust and durable and can carry much higher currents than most other types of gas discharge tube. Some examples have been in continuous service, rectifying 50-amperecurrents, for decades.

Invented in 1902 byPeter Cooper Hewitt,mercury-arc rectifiers were used to provide power for industrial motors,electric railways,streetcars,andelectric locomotives,as well as for radiotransmittersand forhigh-voltage direct current(HVDC) power transmission. They were the primary method of high power rectification before the advent ofsemiconductorrectifiers, such asdiodes,thyristorsandgate turn-off thyristors(GTOs) in the 1970s. These solid state rectifiers have almost completely replaced mercury-arc rectifiers thanks to their higher reliability, lower cost and maintenance and lower environmental risk.[3]

History

[edit]

In 1882Jules Jaminand G. Maneuvrier observed the rectifying properties of a mercury arc.[4][5]The mercury arc rectifier was invented byPeter Cooper Hewittin 1902 and further developed throughout the 1920s and 1930s by researchers in both Europe and North America. Before its invention, the only way to convert AC current provided by utilities to DC was by using expensive, inefficient, and high-maintenancerotary convertersor motor–generator sets. Mercury-arc rectifiers or "converters" were used for charging storage batteries,arc lightingsystems,[6]the DC traction motors fortrolleybuses,trams, and subways, and electroplating equipment. The mercury rectifier was used well into the 1970s, when it was finally replaced bysemiconductor rectifiers.

Operating principles

[edit]

Operation of the rectifier relies on an electricalarcdischarge betweenelectrodesin a sealed envelope containing mercury vapor at very low pressure. A pool of liquid mercury acts as a self-renewingcathodethat does not deteriorate with time. The mercury emitselectronsfreely, whereas the carbonanodesemit very few electrons even when heated, so the current of electrons can only pass through the tube in one direction, from cathode to anode, which allows the tube to rectify alternating current.

When an arc is formed, electrons are emitted from the surface of the pool, causingionizationof mercury vapor along the path towards the anodes. The mercuryionsare attracted towards the cathode, and the resulting ionic bombardment of the pool maintains the temperature of theemission spot,so long as a current of a few amperes continues.

While the current is carried by electrons, the positive ions returning to the cathode allow the conduction path to be largely unaffected by thespace chargeeffects which limit the performance ofvacuum tubes.Consequently, the valve can carry high currents at lowarc voltages(typically 20–30 V) and so is an efficient rectifier. Hot-cathode, gas discharge tubes such as thethyratronmay also achieve similar levels of efficiency but heated cathode filaments are delicate and have a short operating life when used at high current.

The temperature of the envelope must be carefully controlled, since the behaviour of the arc is determined largely by thevapor pressureof the mercury, which in turn is set by the coolest spot on the enclosure wall. A typical design maintains temperature at 40 °C (104 °F) and a mercury vapor pressure of 7millipascals.

The mercury ions emit light at characteristic wavelengths, the relative intensities of which are determined by the pressure of the vapor. At the low pressure within a rectifier, the light appears pale blue-violet and contains muchultravioletlight.

Construction

[edit]The construction of a mercury arc valve takes one of two basic forms — the glass-bulb type and the steel-tank type. Steel-tank valves were used for higher current ratings above approximately 500 A.

Glass-bulb valves

[edit]

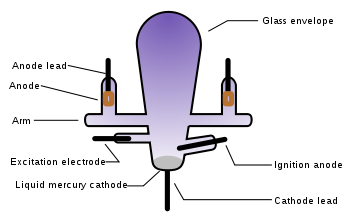

The earliest type of mercury vapor electric rectifier consists of an evacuated glass bulb with a pool of liquid mercury sitting in the bottom as thecathode.[7]Over it curves the glass bulb, which condenses the mercury that is evaporated as the device operates. The glass envelope has one or more arms withgraphiterods asanodes.Their number depends on the application, with one anode usually provided per phase. The shape of the anode arms ensures that any mercury that condenses on the glass walls drains back into the main pool quickly to avoid providing a conductive path between the cathode and respective anode.

Glass envelope rectifiers can handle hundreds of kilowatts of direct-current power in a single unit. A six-phase rectifier rated 150 amperes has a glass envelope approximately 600 mm (24 inches) high by 300 mm (12 inches) outside diameter. These rectifiers will contain several kilograms of liquid mercury. The large size of the envelope is required due to the low thermal conductivity of glass. Mercury vapor in the upper part of the envelope must dissipate heat through the glass envelope in order to condense and return to the cathode pool. Some glass tubes were immersed in an oil bath to better control the temperature.

The current-carrying capacity of a glass-bulb rectifier is limited partly by the fragility of the glass envelope (the size of which increases with rated power) and partly by the size of the wires fused into the glass envelope for connection of the anodes and cathode. Development of high-current rectifiers required leadwire materials and glass with very similar coefficients of thermal expansion in order to prevent leakage of air into the envelope. Current ratings of up to 500 A had been achieved by the mid-1930s, but most rectifiers for current ratings above this were realised using the more robust steel-tank design.

Steel-tank valves

[edit]For larger valves, a steel tank with ceramic insulators for the electrodes is used, with a vacuum pump system to counteract slight leakage of air into the tank around imperfect seals. Steel-tank valves, with water cooling for the tank, were developed with current ratings of several thousand amps.

Like glass-bulb valves, steel-tank mercury arc valves were built with only a single anode per tank (a type also known as theexcitron) or with multiple anodes per tank. Multiple-anode valves were usually used for multi-phase rectifier circuits (with 2, 3, 6 or 12 anodes per tank) but in HVDC applications, multiple anodes were often simply connected in parallel in order to increase the current rating.

Starting (ignition)

[edit]A conventional mercury-arc rectifier is started by a brief high-voltage arc within the rectifier, between the cathode pool and a starting electrode. The starting electrode is brought into contact with the pool and allowed to pass current through an inductive circuit. The contact with the pool is then broken, resulting in a highemfand an arc discharge.

The momentary contact between the starting electrode and the pool may be achieved by a number of methods, including:

- allowing an externalelectromagnetto pull the electrode into contact with the pool; the electromagnet can also serve as the starting inductance,

- arranging the electromagnet to tip the bulb of a small rectifier, just enough to allow mercury from the pool to reach the starting electrode,

- providing a narrow neck of mercury between two pools, and by passing a very high current at negligiblevoltagethrough the neck, displacing the mercury bymagnetostriction,thus opening the circuit,

- Passing current into the mercury pool through abimetallic strip,which warms up under the heating action of the current and bends in such a way as to break the contact with the pool.

Excitation

[edit]Since momentary interruptions or reductions of output current may cause the cathode spot to extinguish, many rectifiers incorporate an additional electrode to maintain an arc whenever the plant is in use. Typically, a two or three phase supply of a few amperes passes through smallexcitation anodes.A magnetically shunted transformer of a few hundred VA rating is commonly used to provide this supply.

This excitation orkeep-alivecircuit was necessary for single-phase rectifiers such as the excitron and for mercury-arc rectifiers used in the high-voltage supply ofradiotelegraphytransmitters, as current flow was regularly interrupted every time theMorse keywas released.[8]

Grid control

[edit]Both glass and metal envelope rectifiers may have control grids inserted between the anode and cathode.

Installation of a control grid between the anode and the pool cathode allows control of the conduction of the valve, thereby giving control of the mean output voltage produced by the rectifier. Start of the current flow can be delayed past the point at which the arc would form in an uncontrolled valve. This allows the output voltage of a valve group to be adjusted by delaying the firing point, and allows controlled mercury-arc valves to form the active switching elements in aninverterconverting direct current into alternating current.

To maintain the valve in the non-conducting state, a negative bias of a few volts or tens of volts is applied to the grid. As a result, electrons emitted from the cathode are repelled away from the grid, back towards the cathode, and so are prevented from reaching the anode. With a small positive bias applied to the grid, electrons pass through the grid, towards the anode, and the process of establishing an arc discharge can commence. However, once the arc has been established, it cannot be stopped by grid action, because the positive mercury ions produced by ionisation are attracted to the negatively charged grid and effectively neutralise it. The only way of stopping conduction is to make the external circuit force the current to drop below a (low) critical current.

Although grid-controlled mercury-arc valves bear a superficial resemblance totriodevalves, mercury-arc valves cannot be used as amplifiers except at extremely low values of current, well below the critical current needed to maintain the arc.

Anode grading electrodes

[edit]

Mercury-arc valves are prone to an effect calledarc-back(orbackfire), whereby the valve conducts in the reverse direction when the voltage across it is negative. Arc-backs can be damaging or destructive to the valve, as well as creating high short-circuit currents in the external circuit, and are more prevalent at higher voltages. One example of the problems caused by backfire occurred in 1960 subsequent to the electrification of the Glasgow North Suburban Railway where steam services had to be re-introduced after several mishaps.[9]For many years this effect limited the practical operating voltage of mercury-arc valves to a few kilovolts.

The solution was found to be to include grading electrodes between the anode and control grid, connected to an externalresistor-capacitordivider circuit.[10]Dr.Uno Lammconducted pioneering work atASEAinSwedenon this problem throughout the 1930s and 1940s, leading to the first truly practical mercury-arc valve for HVDC transmission, which was put into service on the 20 MW, 100 kV HVDC link from mainland Sweden to the island ofGotlandin 1954.

Uno Lamm's work on high voltage mercury-arc valves led him to be known as the "Father of HVDC" power transmission[11]and inspired theIEEEto dedicate an award named after him, for outstanding contributions in the field of HVDC.

Mercury arc valves with grading electrodes of this type were developed up to voltage ratings of 150 kV. However, the tall porcelain column required to house the grading electrodes was more difficult to cool than the steel tank at cathode potential, so the usable current rating was limited to about 200–300 A per anode. Therefore, Mercury arc valves for HVDC were often constructed with four or six anode columns in parallel. The anode columns were always air-cooled, with the cathode tanks either water-cooled or air-cooled.

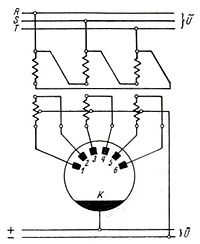

Circuits

[edit]Single-phase mercury-arc rectifiers were rarely used because the current dropped and the arc could be extinguished when the AC voltage changed polarity. The direct current produced by a single-phase rectifier thus contained a varying component (ripple) at twice the power supplyfrequency,which was undesirable in many applications for DC. The solution was to usetwo-, three-, or even six-phaseAC power supplies so that the rectified current would maintain a more constant voltage level. Polyphase rectifiers also balanced the load on the supply system, which is desirable for reasons of system performance and economy.

Most applications of mercury-arc valves for rectifiers usedfull-waverectification with separate pairs of anodes for each phase.

In full-wave rectification both halves of the AC waveform are utilised. Thecathodeis connected to the + side of the DC load, the other side being connected to thecenter tapof thetransformersecondary winding, which always remains at zero potential with respect to ground or earth. For each AC phase, a wire from each end of that phase winding is connected to a separateanode"arm" on the mercury-arc rectifier. When the voltage at each anode becomes positive, it will begin to conduct through the mercury vapor from the cathode. As the anodes of each AC phase are fed from opposite ends of the centre tapped transformer winding, one will always be positive with respect to the center tap and both halves of the AC Waveform will cause current to flow in one direction only through the load. This rectification of the whole AC waveform is thus calledfull-wave rectification.

With three-phase alternating current and full-wave rectification, six anodes were used to provide a smoother direct current. Three phase operation can improve the efficiency of the transformer as well as providing smoother DC current by enabling two anodes to conduct simultaneously. During operation, the arc transfers to the anodes at the highest positive potential (with respect to the cathode).

In HVDC applications, a full-wave three-phasebridge rectifierorGraetz-bridgecircuit was usually used, each valve accommodated in a single tank.

Applications

[edit]As solid-statemetal rectifiersbecame available for low-voltage rectification in the 1920s, mercury arc tubes became limited to higher voltage and especially high-power applications.

Mercury-arc valves were widely used until the 1960s for the conversion of alternating current into direct current for large industrial uses. Applications included power supply for streetcars, electric railways, and variable-voltage power supplies for largeradiotransmitters. Mercury-arc stations were used to provide DC power to legacyEdison-styleDC power gridsin urban centers until the 1950s. In the 1960s,solid-statesilicon devices, firstdiodesand thenthyristors,replaced all lower-power and lower voltage rectifier applications of mercury arc tubes.

Several electric locomotives, including theNew Haven EP5and theVirginian EL-C,carriedignitronson board to rectify incoming AC to traction motor DC.

One of the last major uses of mercury arc valves was in HVDC power transmission, where they were used in many projects until the early 1970s, including theHVDC Inter-Islandlink between the North and South Islands ofNew Zealandand theHVDC Kingsnorthlink fromKingsnorth power stationtoLondon.[12]However, starting about 1975, silicon devices have made mercury-arc rectifiers largely obsolete, even in HVDC applications. The largest ever mercury-arc rectifiers, built byEnglish Electric,were rated at 150kV,1800 A and were used until 2004 at theNelson River DC Transmission Systemhigh-voltage DC-power-transmission project. The valves for the Inter-Island and Kingsnorth projects used four anode columns in parallel, while those of the Nelson River project used six anode columns in parallel in order to obtain the necessary current rating.[13]The Inter-Island link was the last HVDC transmission scheme in operation using mercury arc valves. It was formally decommissioned on 1 August 2012. The mercury arc valve converter stations of the New Zealand scheme were replaced by new thyristor converter stations. A similar mercury arc valve scheme, theHVDC Vancouver Islandlink was replaced by a three-phase AC link.

Mercury arc valves remain in use in someSouth Africanmines and Kenya (atMombasa Polytechnic- Electrical & Electronic department).

Mercury arc valves were used extensively in DC power systems onLondon Underground,[14]and two were still observed to be in operation in 2000 at the disuseddeep-level air-raid shelteratBelsize Park.[15]After they were no longer needed as shelters, Belsize Park and several other deep shelters were used as secure storage, particularly for music and television archives. This led to the mercury-arc rectifier at theGoodge Streetshelter featuring in an early episode ofDoctor Whoas an alien brain, cast for its "eerie glow".[16]

Auckland's Museum Of Transport And Technology (MOTAT) still employs a Mercury arc valve to provide power to the tram which carries visitors between its two sites.[17]

Others

[edit]Special types of single-phase mercury-arc rectifiers are theIgnitronand theExcitron.The Excitron is similar to other types of valve described above but depends critically on the existence of an excitation anode to maintain an arc discharge during the half-cycle when the valve is not conducting current. The Ignitron dispenses with excitation anodes by igniting the arc each time conduction is required to start. In this way, ignitrons also avoid the need for control grids.

In 1919, the book "Cyclopedia of Telephony & Telegraphy Vol. 1"[18]described anamplifierfortelephonesignals that used a magnetic field tomodulatean arc in a mercury rectifier tube. This was never commercially important.

Environmental hazard

[edit]Mercury compounds are toxic, highly persistent in the environment, and present a danger to humans and the environment. The use of large quantities of mercury in fragile glass envelopes presents a hazard of potential release of mercury to the environment should the glass bulb be broken. Some HVDC converter stations have required extensive clean-up to eliminate traces of mercury emitted from the station over its service life. Steel tank rectifiers frequently required vacuum pumps, which continually emitted small amounts of mercury vapor.

References

[edit]- ^Electrical Year Book 1937,Emmott and Company, Manchester, England, pp 180-185

- ^Rissik, H., Mercury-Arc Current Converters, Pitman. 1941.

- ^"History | IEEE Power & Energy Magazine".magazine.ieee-pes.org.Retrieved17 January2017.

- ^Reaction Current of the Electric Arc,Comptes rendus de l'Académie des Sciences,vol. 94, p. 1615, June 19, 1882,English translationinThe London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science,Volume 14, 1882 - Issue 86, p. 154 - 157.

- ^Power Electronics.PHI Learning Pvt. January 2004.ISBN9788120323964.

- ^I.C.S. Reference Library volume 4B,International Textbook Company,Scranton PA 1908, section 53, page 34.

- ^Howatson A H (1965). "8".An Introduction to Gas Discharges.Oxford:Pergamon Press.ISBN0-08-020575-5.

- ^Francis Edward Handy (1926).The Radio Amateur's Handbook(1st ed.). Hartford, CT:American Radio Relay League.pp. 78–81.

- ^"MoT Failures"(PDF).www.railwaysarchive.co.uk.Retrieved2019-12-29.

- ^Cory, B.J.; Adamson, C.; Ainsworth, J.D.; Freris, L.L.; Funke, B.; Harris, L.A.; Sykes, J.H.M. (1965). "Chapter 2".High voltage direct current converters and systems.Macdonald & Co. Ltd.

- ^Gould, William R. (1992)."August Uno Lamm".Memorial Tributes.Vol. 5. National Academy of Engineering.doi:10.17226/1966.ISBN978-0-309-04689-3.RetrievedAugust 24,2005.

- ^Calverley T.E., Gavrilovic, A., Last F.H., Mott C.W., The Kingsnorth-Beddington-Willesden DC Link, CIGRE session, Paris, 1968.

- ^Cogle, T.C.J, The Nelson River Project - Manitoba Hydro exploits sub-arctic hydro power resources, Electrical Review, 23 November 1973.

- ^London Transport in 1955,p. 43, London Transport Executive, 1956OCLC867841889

- ^Catford, Nick (27 January 2000)."Belsize Park Deep Shelter-sb".Subterranea Britannica.Archived fromthe originalon 9 May 2020.Retrieved9 May2020.

- ^Antony Clayton,Subterranean City: Beneath the Streets of London,p. 146, Historical Publications, 2000ISBN0948667699.

- ^Drayton, Phoebe. 2021. Meet MOTAT's Mercury Arc Rectifier. New Zealand: The Museum of Transport and Technology (MOTAT). First published: 08 December 2021. URLhttps://www.motat.nz/collections-and-stories/stories/meet-motats-mercury-arc-rectifier

- ^TheProject GutenbergEBook ofCyclopedia of Telephony & Telegraphy Vol. 1

Further reading

[edit]- ABB page on the history of high voltage direct current transmission

- The Tube Collector Virtual Museum. Description of mercury arc rectifiers and further links, including photographs

- 1903 illustrated article –A Great Electrical Discovery

- Testing The 50 Year Old Mercury Arc Rectifier — video with circuit diagrams, closeup views, explanation of operation