Fiber

This articleneeds additional citations forverification.(April 2009) |

| Part of a series on |

| Fiber |

|---|

|

| Natural fibers |

| Human-made fibers |

Fiberorfibre(British English;from Latin:fibra[1]) is anaturalorartificialsubstance that is significantly longer than it is wide.[2]Fibers are often used in the manufacture of other materials. The strongest engineering materials often incorporate fibers, for examplecarbon fiberandultra-high-molecular-weight polyethylene.

Synthetic fibers can often be produced very cheaply and in large amounts compared to natural fibers, but for clothing natural fibers have some benefits, such as comfort, over their synthetic counterparts.

Natural fibers

Natural fibers develop or occur in the fiber shape, and include those produced by plants, animals, and geological processes.[2]They can be classified according to their origin:

- Vegetable fibersare generally based on arrangements ofcellulose,often withlignin:examples includecotton,hemp,jute,flax,abaca,piña,ramie,sisal,bagasse,andbanana.Plant fibers are employed in the manufacture ofpaperandtextile(cloth), anddietary fiberis an important component of human nutrition.

- Wood fiber,distinguished from vegetable fiber, is from tree sources. Forms include groundwood,lacebark,thermomechanical pulp (TMP), and bleached or unbleachedkraftor sulfite pulps. Kraft and sulfite refer to the type of pulping process used to remove the lignin bonding the original wood structure, thus freeing the fibers for use in paper andengineered woodproducts such asfiberboard.

- Animal fibersconsist largely of particular proteins. Instances aresilkwormsilk,spider silk,sinew,catgut,wool,sea silkand hair such ascashmere wool,mohairandangora,fur such as sheepskin, rabbit, mink, fox, beaver, etc.

- Mineral fibersinclude theasbestosgroup. Asbestos is the only naturally occurring longmineralfiber. Six minerals have been classified as "asbestos" includingchrysotileof theserpentineclass and those belonging to theamphiboleclass:amosite,crocidolite,tremolite,anthophylliteandactinolite.Short, fiber-like minerals includewollastoniteandpalygorskite.

- Biological fibers, also known asfibrous proteinsorprotein filaments,consist largely of biologically relevant and biologically very important proteins, in which mutations or other genetic defects can lead tosevere diseases.Instances include thecollagen[3]family of proteins,tendons,muscle proteinslikeactin,cell proteins likemicrotubules[citation needed]and many others, such asspider silk,sinew,andhair.

Artificial fibers

Artificial or chemical fibers are fibers whose chemical composition, structure, and properties are significantly modified during the manufacturing process. In fashion, a fiber is a long and thin strand or thread of material that can beknitorwoveninto a fabric.[4]Artificial fibers consist of regenerated fibers and synthetic fibers.

Semi-synthetic fibers

Semi-synthetic fibers are made from raw materials with naturally long-chainpolymerstructure and are only modified and partially degraded by chemical processes, in contrast to completely synthetic fibers such asnylon(polyamide) ordacron(polyester), which the chemist synthesizes from low-molecular weight compounds by polymerization (chain-building) reactions. The earliest semi-synthetic fiber is the cellulose regenerated fiber,rayon.[5]Most semi-synthetic fibers are cellulose regenerated fibers.

Cellulose regenerated fibers

Cellulose fibersare a subset of artificial fibers, regenerated from naturalcellulose.The cellulose comes from various sources: rayon from tree wood fiber,bamboo fiberfrom bamboo, seacell fromseaweed,etc. In the production of these fibers, the cellulose is reduced to a fairly pure form as a viscous mass and formed into fibers by extrusion through spinnerets. Therefore, the manufacturing process leaves few characteristics distinctive of the natural source material in the finished products.

Some examples of this fiber type are:

- rayon

- Lyocell,a brand of rayon

- Modal

- diacetate fiber

- triacetate fiber.

Historically, cellulose diacetate and -triacetate were classified under the term rayon, but are now considered distinct materials.

Synthetic fibers

Syntheticcome entirely from synthetic materials such aspetrochemicals,unlike those artificial fibers derived from such natural substances as cellulose or protein.[6]

Fiber classification in reinforced plastics falls into two classes: (i) short fibers, also known as discontinuous fibers, with a general aspect ratio (defined as the ratio of fiber length to diameter) between 20 and 60, and (ii) long fibers, also known as continuous fibers, the general aspect ratio is between 200 and 500.[7]

Metallic fibers

Metallic fiberscan be drawn from ductile metals such as copper, gold or silver and extruded or deposited from more brittle ones, such as nickel, aluminum or iron.

Carbon fiber

Carbon fibersare often based on oxidized and viapyrolysiscarbonized polymers likePAN,but the end product is almost pure carbon.

Silicon carbide fiber

Silicon carbidefibers, where the basic polymers are nothydrocarbonsbut polymers, where about 50% of the carbon atoms are replaced by silicon atoms, so-called poly-carbo-silanes.The pyrolysis yields an amorphous silicon carbide, including mostly other elements like oxygen, titanium, or aluminium, but with mechanical properties very similar to those of carbon fibers.

Fiberglass

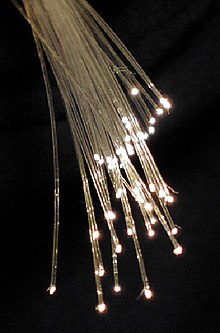

Fiberglass,made from specific glass, andoptical fiber,made from purified naturalquartz,are also artificial fibers that come from natural raw materials,silica fiber,made fromsodium silicate(water glass) andbasalt fibermade from melted basalt.

Mineral fibers

Mineral fibers can be particularly strong because they are formed with a low number of surface defects;asbestosis a common one.[8]

Polymer fibers

- Polymer fibers are a subset of artificial fibers, which are based on synthetic chemicals (often frompetrochemicalsources) rather than arising from natural materials by a purely physical process. These fibers are made from:

- polyamidenylon

- PET or PBTpolyester

- phenol-formaldehyde (PF)

- polyvinyl chloride fiber (PVC)vinyon

- polyolefins (PP and PE)olefin fiber

- acrylicpolyesters, purepolyesterPAN fibers are used to makecarbon fiberby roasting them in a low oxygen environment. Traditional acrylic fiber is used more often as a synthetic replacement for wool. Carbon fibers and PF fibers are noted as two resin-based fibers that are notthermoplastic,most others can be melted.

- aromatic polyamids(aramids) such asTwaron,KevlarandNomexthermally degrade at high temperatures and do not melt. These fibers have strong bonding between polymer chains

- polyethylene(PE), eventually with extremely long chains /HMPE(e.g. Dyneema or Spectra).

- Elastomerscan even be used, e.g.spandexalthough urethane fibers are starting to replace spandex technology.

- polyurethanefiber

- Elastolefin

- Coextruded fibers have two distinct polymers forming the fiber, usually as a core-sheath or side by side. Coated fibers exist such as nickel-coated to provide static elimination, silver-coated to provide anti-bacterial properties and aluminum-coated to provide RF deflection forradar chaff.Radar chaff is actually a spool of continuous glass tow that has been aluminum coated. An aircraft-mounted high speed cutter chops it up as it spews from a moving aircraft to confuse radar signals.

Microfibers

Invented in Japan in the early 1980s, microfibers are also known as microdenier fibers. Acrylic, nylon, polyester, lyocell and rayon can be produced as microfibers. In 1986, Hoechst A.G. of Germany produced microfiber in Europe. This fiber made it way into the United States in 1990 by DuPont.[9]

Microfibersintextilesrefer to sub-denier fiber (such as polyester drawn to 0.5 denier).DenierandDtexare two measurements of fiber yield based on weight and length. If the fiber density is known, you also have a fiber diameter, otherwise it is simpler to measure diameters in micrometers. Microfibers in technical fibers refer to ultra-fine fibers (glass or meltblownthermoplastics) often used in filtration. Newer fiber designs include extruding fiber that splits into multiple finer fibers. Most synthetic fibers are round in cross-section, but special designs can be hollow, oval, star-shaped ortrilobal.The latter design provides more optically reflective properties. Synthetic textile fibers are often crimped to provide bulk in a woven, non woven or knitted structure. Fiber surfaces can also be dull or bright. Dull surfaces reflect more light while bright tends to transmit light and make the fiber more transparent.

Very short and/or irregular fibers have been called fibrils. Naturalcellulose,such ascottonor bleachedkraft,show smaller fibrils jutting out and away from the main fiber structure.[10]

Typical properties of selected fibers

Fibers can be divided into natural and artificial (synthetic) substance, their properties can affect their performance in many applications. Synthetic fiber materials are increasingly replacing other conventional materials like glass and wood in a number of applications.[11]This is because artificial fibers can be engineered chemically, physically, and mechanically to suit particular technical engineering.[12]In choosing a fiber type, a manufacturer would balance their properties with the technical requirements of the applications. Various fibers are available to select for manufacturing. Here are typical properties of the sample natural fibers as compared to the properties of artificial fibers.

| Fiber type | Fiber Diameter

(in) |

Specific Gravity | Tensile Strength

(Ksi) |

Elastic Modulus

(Ksi) |

Elongation at Break

(%) |

Water Absorption

(%) |

| Wood Fiber

(Kraft Pulp) |

0.001-0.003 | 1.5 | 51-290 | 1500-5800 | N/A | 50-75 |

| Musamba | N/A | N/A | 12 | 130 | 9.7 | N/A |

| Coconut | 0.004-0.016 | 1.12-1.15 | 17.4-29 | 2750-3770 | 10-25 | 130-180 |

| Sisal | 0.008-0.016[15] | 1.45[15] | 40-82.4 | 1880-3770 | 3-5 | 60-70 |

| Sugar CaneBagasse | 0.008-0.016 | 1.2-1.3 | 26.7-42 | 2175-2750 | 1.1[16] | 70-75 |

| Bamboo | 0.002-0.016 | 1.5 | 50.8-72.5 | 4780-5800 | N/A | 40-45 |

| Jute | 0.004-0.008 | 1.02-1.04 | 36.3-50.8 | 3770-4640 | 1.5-1.9 | 28.64[17] |

| Elephant grass | 0.003-0.016[18] | 0.818[18] | 25.8 | 710 | 3.6 | N/Ab |

| a Adapted from ACI 544. IR-96 P58, reference [12] P240 and [13]

b N/A means properties not readily available or not applicable | ||||||

| Fiber type | Fiber Diameter

(0.001 in) |

Specific Gravity | Tensile Strength (Ksi) | Elasticity Modulus

(Ksi) |

Elongation at Break

(%) |

Water Absorption

(%) |

Melting Point

(°C) |

Maximum Working

Temp (°C) |

| Steel | 4-40 | 7.8 | 70-380 | 30,000 | 0.5-3.5 | nil | 1370[19] | 760[19] |

| Glass | 0.3-0.8 | 2.5 | 220-580 | 10,400-11,600 | 2-4 | N/A | 1300 | 1000 |

| Carbon | 0.3-0.35 | 0.90 | 260-380 | 33,400-55,100 | 0.5-1.5 | nil | 3652-3697[20] | N/A |

| Nylon | 0.9 | 1.14 | 140 | 750 | 20-30 | 2.8-5.0 | 220-265 | 199 |

| Acrylics | 0.2-0.7 | 1.14-1.18 | 39-145 | 2,500-2,800 | 20-40 | 1.0-2.5 | Decomp | 180 |

| Aramid | 0.4-0.5 | 1.38-1.45 | 300-450 | 9,000-17,000 | 2-12 | 1.2-4.3 | Decomp | 450 |

| Polyester | 0.4-3.0 | 1.38 | 40-170 | 2,500 | 8-30 | 0.4 | 260 | 170 |

| Polypropylene | 0.8-8.0 | 0.9 | 65-100 | 500-750 | 10-20 | nil | 165 | 100 |

| Polyethylene

Low High |

1.0-40.0 |

0.92 0.95 |

11-17 50-71 |

725 |

25-50 20-30 |

nil nil |

110 135 |

55 65 |

| a Adapted from ACI 544. IR-96 P40, reference [12] P240, [11] P209 and [13]

b N/A means properties not readily available or not applicable | ||||||||

The tables above just show typical properties of fibers, in fact there are more properties which could be referred as follows (from a to z):[14]

Arc Resistance,Biodegradable,Coefficient of LinearThermal Expansion,Continuous Service Temperature,Density of Plastics,Ductile/BrittleTransition Temperature, Elongation at Break, Elongation at Yield, Fire Resistance, Flexibility, Gamma Radiation Resistance, Gloss,Glass Transition Temperature,Hardness,Heat Deflection Temperature,Shrinkage,Stiffness,Ultimate tensile strength,Thermal Insulation,Toughness,Transparency,UV Light Resistance, VolumeResistivity,Water absorption,Young's Modulus

See also

- Ceramic matrix composite

- Dietary fiber

- Fiber crop

- Fiber simulation

- Fibers in Differential Geometry

- Molded fiber

- Nerve fiber

- Optical fiber

References

- ^Harper, Douglas."fiber".Online Etymology Dictionary.

- ^abKadolph, Sara (2002).Textiles.Prentice Hall.ISBN978-0-13-025443-6.

- ^Saad, Mohamed (Oct 1994).Low resolution structure and packing investigations of collagen crystalline domains in tendon using Synchrotron Radiation X-rays, Structure factors determination, evaluation of Isomorphous Replacement methods and other modeling.PhD Thesis, Université Joseph Fourier Grenoble I. pp. 1–221.doi:10.13140/2.1.4776.7844.

- ^"man-made fibre".Encyclopædia Britannica.Encyclopædia Britannica, Inc.2013.

- ^Kauffman, George B. (1993). "Rayon: the first semi-synthetic fiber product".Journal of Chemical Education.70(11): 887.Bibcode:1993JChEd..70..887K.doi:10.1021/ed070p887.

- ^"synthetic fibre".Encyclopædia Britannica.Encyclopædia Britannica, Inc. 2013.

- ^Serope Kalpakjian, Steven R Schmid. "Manufacturing Engineering and Technology". International edition. 4th Ed. Prentice Hall, Inc. 2001.ISBN0-13-017440-8.

- ^James Edward Gordon; Philip Ball (2006).The new science of strong materials, or, Why you don't fall through the floor.Princeton University Press.ISBN978-0-691-12548-0.Retrieved28 October2011.

- ^Cohen, Allen (11 November 2011).J. J. Pizzuto's Fabric Science(10th ed.). Fairchild Books. p. 51.ISBN978-1-60901-380-6.

- ^Hans-J. Koslowski. "Man-Made Fibers Dictionary". Second edition. Deutscher Fachverlag. 2009ISBN3-86641-163-4

- ^Shenoy, Aroon (1999).Rheology of Filled Polymer Systems.Kluwer Academic Publishers.ISBN978-0-412-83100-3.

- ^Hollaway, C. (1990).Polymers and Polymer Composites in Construction.Great Britain: Bulter and Tanner Ltd. p. 209.ISBN978-0-7277-1521-0.

- ^Design and Control of Concrete Mixtures ". Sixteenth Edition.United States of America: Portland Cement Association. 2018. pp. 237–247.ISBN978-0-89312-277-5.

- ^ab"Polymer Properties – Omexus by Special Chem".

- ^ab"Sisal Fiber – World of Sisal".

- ^Sain, M. (2014). "The use of sugarcane bagasse fibres as reinforcements in composites". In Faruk, Omar; Sain, Mohini (eds.).Biofiber Reinforcements in Composite Materials.Elsevier Science & Technology.ISBN9781782421221.

- ^Narayanan, Venkateshwaran (2012). "Mechanical and Water Absorption Properties of Woven Jute/Banana Hybrid Composites".Fibers and Polymers.13(7, 907–914).doi:10.1007/s12221-012-0907-0.

- ^abK. Murali Mohan, Rao (2007). "Tensile Properties of Elephant grass fiber reinforced polymer Composites".Journal of Materials Science.42(9, 3266–3272).doi:10.1007/s10853-006-0657-8.

- ^ab"Metallic Materials – TEADIT"(PDF).

- ^"Carbon Fiber – Americans Elements".