Lamination

This article has multiple issues.Please helpimprove itor discuss these issues on thetalk page.(Learn how and when to remove these template messages)

|

Laminationis the technique/process of manufacturing amaterialin multiple layers, so that thecomposite materialachieves improvedstrength,stability,sound insulation,appearance,or other properties from the use of the differing materials, such as plastic. Alaminateis a layered object or material assembled usingheat,pressure,welding,oradhesives.[1]Various coating machines,machine pressesandcalenderingequipment are used.

Materials

[edit]There are different lamination processes, depending primarily on the type or types of materials to be laminated. The materials used in laminates can be identical or different, depending on the object to be laminated, the process and the desired properties.

Textile

[edit]Laminated fabricare widely used in different fields of human activity, including medical and military.[2]: 148 Woven fabrics (organic and inorganic based) are usually laminated by different chemical polymers to give them useful properties like chemical resistance, dust, grease,photoluminescence(glowing and other light-effects e.g. inhigh-visibility clothing),tear strength,stiffness, thickness, and being wind proof.[3][2]: 2, 16, 18 Coated fabricsmay be considered as a subtype of laminated fabrics.[2]: 1 Nonwoven fabrics(e.g. fiberglass) are also often laminated. According to a 2002 source, the nonwovens fabric industry was the biggest single consumer of different polymer binding resins.[2]: 16

Materials used in production of coated and laminated fabrics are generally subjected to heat treatment.[2]: 32 Thermoplasticsandthermosettingplastics (e.g.formaldehydepolymers) are equally used in laminating and coating textile industry.[2]: 32 In 2002 primary materials used includedpolyvinyl acetate,acrylics,polyvinyl chloride(PVC),polyurethanes,andnaturalandsynthetic rubbers.[2]: 33 Copolymersand terpolymers were also in use.[2]: 33

Thin-films of plastics were in wide use as well. Materials varied frompolyethyleneandPVCtokaptondepending on application. In automotive industry for example the PVC/acrylonitrilebutadiene-styrene(ABS) mixtures were often applied for interiors by laminating onto apolyurethane foamto give a soft-touch properties.[2]: 42 Specialty films were used in protective clothing,.e.g.polytetrafluoroethylene(PTFE),polyurethaneetc.[2]: 42

Glass

[edit]Plastic filmcan be used to laminate either side of a sheet ofglass.Vehiclewindshieldsare commonly made ascompositescreated by laminating a tough plastic film between two layers of glass. This is to prevent shards of glass detaching from the windshield in case it breaks.

Wood

[edit]Plywoodis a common example of a laminate using the same material in each layer combined with an adhesive. Glued and laminated dimensional timber is used in the construction industry to make beams (glued laminated timber,orGlulam), in sizes larger and stronger than those that can be obtained from single pieces of wood. Another reason to laminate wooden strips into beams is quality control, as with this method each and every strip can be inspected before it becomes part of a highly stressed component.

Examples of laminate materials includemelamineadhesive countertop surfacing andplywood.[4]Decorative laminatesand some modernmillworkcomponents are produced with decorative papers with a layer of overlay on top of the decorative paper, set before pressing them with thermoprocessing into high-pressure decorative laminates (HPDL).[5]A new type of HPDL is produced using realwood veneerormultilaminar veneeras top surface.[citation needed]High-pressure laminates consists of laminates "molded and cured at pressures not lower than 1,000 lb per sq in.(70 kg per cm2) and more commonly in the range of 1,200 to 2,000 lb per sq in. (84 to 140 kg per cm2).[6]Meanwhile, low pressure laminate is defined as "a plastic laminate molded and cured at pressures in general of 400 pounds per square inch (approximately 27 atmospheres or 2.8 × 106 pascals).[7]

Paper

[edit]

Corrugated fiberboardboxes are examples of laminated structures, where an inner core provides rigidity and strength, and the outer layers provide a smooth surface. A starch-based adhesive is usually used.

Laminating paper products, such asphotographs,can prevent them from becoming creased, faded, water damaged, wrinkled, stained, smudged, abraded, or marked by grease or fingerprints.Photo identificationcards andcredit cardsare almost always laminated with plastic film. Boxes and other containers may be laminated using heat seal layers, extrusion coatings, pressure sensitive adhesives,UV coating,etc.

Lamination is also used in sculpture using wood or resin. An example of an artist who used lamination in his work is the AmericanFloyd Shaman.

Laminates can be used to add properties to a surface, usually printed paper, that would not have them otherwise, such as with the use oflamination paper.Sheets ofvinylimpregnated withferro-magneticmaterial can allow portable printed images to bond to magnets, such as for a custom bulletin board or a visual presentation. Specially surfaced plastic sheets can be laminated over a printed image to allow them to be safely written upon, such as withdry erasemarkers or chalk. Multiple translucent printed images may be laminated in layers to achieve certain visual effects or to holdholographicimages. Printing businesses that do commercial lamination keep a variety of laminates on hand, as the process for bonding different types is generally similar when working with thin materials.

Paper is normally laminated onparticleorfiberboardsgiving a good-looking and resistant surface for use asfurniture,decorationpanelsandflooring.[8]

Paper laminations are also used inpackaging.For example,juiceboxesare fabricated fromliquid packaging boardwhich is usually six layers of paper, polyethylene, and aluminum foil. Paper is used in the lamination to shape the product and give the juicebox an extra source of strength.

The base is most oftenparticle- orfiberboards,then some layers of absorbentkraft paper.The last layers are adecor papercovered with anoverlay.The lamination papers are covered with an inertresin,oftenmelamine,which is cured to form a hardcompositewith the structure of paper. The laminates may also have aliningon the back side oflaminating kraftto compensate for the tension created by the top side lamination. Cheaper particle boards may have only a lining of laminating kraft to give surface washability and resistance to wear.

Thedecor papercan also be processed under heat and low/high pressure to create a melamine laminated sheet, that has several applications. The absorbent kraft paper is a normalkraft paperwith controlledabsorbency,which means a high degree ofporosity.It is made of clean lowkappahardwood kraft with gooduniformity.Thegrammageis 80 - 120 g/m2and normally 2-4 plies are used.[8]The decor paper is the most critical of the lamination papers as it gives the visual appearance of the laminate. The impregnationresinandcellulosehave about the samerefraction indexwhich means that the cellulose fibers of thepaperappear as a shade and only thedyestuffsandpigmentsare visible. Due to this the decor paper demands extreme cleanness and is produced only on smallpaper machineswithgrammage50 - 150 g/m2.[8]The overlay paper havegrammageof 18 – 50 m2and is made of purecellulose,thus it must be made of well delignifiedpulp.It becomes transparent after impregnation letting the appearance of the decor paper come through. The laminating kraft have agrammageof 70 - 150 g/m2and is a smooth densekraft paper.[8]

Metal

[edit]Electrical equipment such astransformersandmotorsusually use anelectrical steel laminate coatingsto form the core of thecoilsused to producemagnetic fields.The thin lamination reduces the power loss due toeddy currents.Fiber metal laminateis an example of thin metal laminated by, a glass fiber-reinforced and epoxy-glued sheets.

Microelectronics

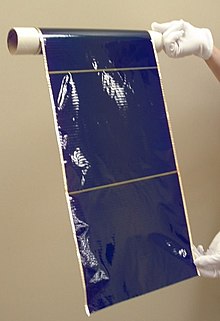

[edit]Lamination is widely used in production of electronic components such as PV solar cells.[9]

Film types

[edit]Laminateplastic filmis generally categorized into these five categories:

- Standard thermal laminating films

- Low-temperature thermal laminating films

- Heat set (or heat-assisted) laminating films

- Pressure-sensitive films

- Liquid laminate

See also

[edit]- Laminated bow– Type of archery bow

- Laminator– Device used to laminate paper or card stock

- Converting– Specialist in combining raw materials to create new products

- Cladding (metalworking)– bonding together of dissimilar metals

- Composite laminates– Assembly of layers of fibrous composite materials

- Composite material– Material made from a combination of two or more unlike substances

- Carbon-fibre reinforced plastic– Light, strong and rigid composite material

- Glass-reinforced plastic– Type of plastic reinforced by glass fibre

- Delamination– Mode of failure for which a material fractures into layers

- Void (composites)– Empty space in mixed materials

References

[edit]- ^Carter, Richard."Method of laminating multiple layers".Google Patents.Archivedfrom the original on 24 June 2016.Retrieved15 February2015.

- ^abcdefghijFung, Walter (2002).Coated and laminated textiles.Textile Institute. Boca Raton, FL: CRC Press.ISBN1-59124-756-X.OCLC57250766.

- ^Fung, W. (9 May 2002).Coated and Laminated Textiles | ScienceDirect.Woodhead.ISBN9781855735767.Retrieved2021-11-26.

- ^Martin, Alan; Harbison, Sam; Beach, Karen; Cole, Peter (2012-03-30).An Introduction to Radiation Protection 6E.CRC Press.ISBN9781444146073.

- ^"What Is Post-Formed Plastic Laminate?".Delorie Countertops and Doors. 21 January 2015.Archivedfrom the original on 11 July 2018.Retrieved15 February2015.

- ^McGraw-Hill Dictionary of Architecture & Construction

- ^McGraw-Hill Dictionary of Scientific & Technical Terms, 6E, Copyright © 2003 by The McGraw-Hill Companies, Inc.

- ^abcdPaulapuro, Hannu (2000). "5".Paper and Board grades.Papermaking Science and Technology. Vol. 18. Finland: Fapet Oy. pp. 108–111.ISBN952-5216-18-7.

- ^Steim, R.; Chabrecek, P.; Sonderegger, U.; Kindle-Hasse, B.; Siefert, W.; Kroyer, T.; Reinecke, P.; Lanz, T.; Geiger, T.; Hany, R.; Nüesch, F. (2015-05-11)."Laminated fabric as top electrode for organic photovoltaics".Applied Physics Letters.106(19): 193301.Bibcode:2015ApPhL.106s3301S.doi:10.1063/1.4919940.ISSN0003-6951.S2CID119779721.