Machine tool builder

Amachine tool builderis acorporationor person that buildsmachine tools,usually for sale tomanufacturers,who use them to manufacture products. A machine tool builder runs amachine factory,which is part of themachine industry.

The machine tools often makeinterchangeable parts,which are assembled into subassemblies or finished assemblies, ending up sold toconsumers,either directly orthrough other businessesat intermediate links of avalue-adding chain.Alternatively, the machine tools may help makemoldsordies,which then make the parts for the assemblies.

Overview

[edit]The term "machine tool builder" implies a company that builds machine tools for sale to other companies, who then use them to manufacture subsequent products. Macroeconomically, machine tools are only means to ends (with the ends being the manufactured products); they are not the ends themselves. Thus it is in the nature of machine tools that there is a spectrum of relationships between their builders, their users, and the end users of the products that they make.

There is always natural potential for the machine tool users to be the same people as the builders, or to be different people who occupy an intermediate position in the value stream. Markets often have some proclivity for circumventing such a position, although the proclivity is often not absolute. Every variant on the spectrum of relationships has found some instances of empirical embodiment; and over the centuries, trends can be seen for which variants predominated in each era, as described below.

Machine tool builders tend not to be in the business of using the machine tools to manufacture the subsequent products (although exceptions, including chaebol and keiretsu, do exist); and product manufacturers tend not to be in the business of building machine tools. In fact, many machine tool builders are not even in the business of building the control system (typicallyCNC) that animates the machine; and makers of controls tend not to be in the machine building business (or to inhabit only specialized niches within it).

For example,FANUCandSiemensmake controls that are sold to many machine tool builders. Each segment tends to find that crossing into other segments involves becoming a conglomerate of dissimilar businesses, which is an execution headache that they don't need as long as focusing on a narrower field is often more profitable in net effect anyway. This trend can be compared to the trend in which companies choose not to compete against their own distributors. Thus a software company may have an online store, but that store does not undercut the distributors' stores on price.

History

[edit]

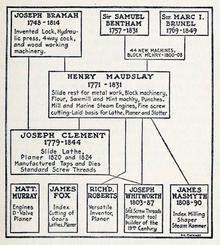

The machine tool industry began gradually in the early nineteenth century with individual toolmakers who innovated in machine tool design and building. The ones that history remembers best includeHenry Maudslay,Joseph Whitworth,Joseph Clement,James Nasmyth,Matthew Murray,Elisha K. Root,Frederick W. Howe, Stephen Fitch, J.D. Alvord, Frederick W. Howe, Richard S. Lawrence, Henry D. Stone,Christopher M. Spencer,Amos Whitney,andFrancis A. Pratt.

The industry then grew into the earliest corporate builders such asBrown & Sharpe,theWarner & Swasey Company,and theoriginal Pratt & Whitney company.In all of these cases, there were product manufacturers who started building machine tools to suit their own inhouse needs, and eventually found that machine tools had become product lines in their own right. (In cases such as B&S and P&W, they became the main or sole product lines.)

In contrast,ColtandFordare good examples of product manufacturers that made significant advances in machine tool building while serving their own inhouse needs, but never became "machine tool builders" in the sense of having machine tools become the products that they sold. National-Acme was an example of a manufacturer and a machine tool builder merging into one company and selling both the machines and the products that they made (screw machinesand fasteners).[1][2]HyundaiandMitsubishiarechaebolandkeiretsuconglomerates (respectively), and their interests cover from ore mine to end user (in actuality if not always nominally).

Until the 1970s, machine tool builder corporations could generally be said to have nationality, and thus it made sense to talk about an American machine tool builder, a German one, or a Japanese one. Since the 1970s, the industry hasglobalizedto the point that assigning nationality to the corporations becomes progressively more meaningless as one travels down the timeline leading up to the present day; currently, most machine tool builders are (or aresubsidiariesof)multinational corporationsorconglomerates.With these companies it is enough to say "multinational corporation based in country X", "multinational corporation founded in country X", etc. Subcategories such as "American machine tool builders" or "Japanese machine tool builders" would be senseless because, for example, companies likeHardingeandYamazaki Mazaktoday have significant operations in many countries.

Trade associations

[edit]Machine tool builders have long hadtrade associations,which have helped with such tasks as establishing industry standards,lobbying(of legislatures and, more often, import-and-export-regulatingagencies), and training programs.[3]For example, the National Machine Tool Builders' Association (NMTBA) was the trade association of U.S. machine tool builders for many decades, and it helped establish standards such as the NMTBmachine taperseries (which made toolholders interchangeable between the different brands of machine on a typical machine shop floor). It has since been merged into theAssociation for Manufacturing Technology(AMT). Other examples have included CECIMO (European Machine Tool Industry Association), the UK'sABMTM,MTTA, andMTA,and the Japan Machine Tool Builders' Association (JMTBA).[3]

Just as machine tool builders have long had trade associations, so have machine tool distributors (dealers). Examples have been the American Machine Tool Distributors’ Association (AMTDA) and the Japan Machine Tool Trade Association (JMTTA).[3]In recent decades the builders' and distributors' associations have cooperated on shared interests to the extent that some of them have merged. For example, the former NMTBA and AMTDA have merged into the AMT.

Trade shows

[edit]Major trade shows of the industry include IMTS (International Manufacturing Technology Show,formerly called the International Machine Tool Show) andEMO(FrenchExposition Mondiale de la Machine Outil,English "Machine Tool World Exposition" ). There are also many smaller trade shows concentrating on specific geographical regions (for example, the Western US, the mid-Atlantic US, the Ruhr Valley, or the Tokyo region) or on specific industries (such as shows tailored especially to themoldmakingindustry).

Historical studies of machine tool building

[edit]In the early 20th century,Joseph Wickham Roewrote a seminal classic of machine tool history,English and American Tool Builders(1916),[4]which is extensively cited by later works. About 20 years later Roe published a biography ofJames Hartness(1937)[5]that also contains some general history of the industry. In 1947,Fred H. Colvinpublished a memoir,Sixty Years with Men and Machines,[6]that contains quite a bit of general history of the industry.

L. T. C. Rolt's 1965 monograph,A Short History of Machine Tools,[7]is a widely read classic, as are the series of monographs that Robert S. Woodbury published during the 1960s, which were collected into a volume in 1972 asStudies in the History of Machine Tools.[8]

In 1970,Wayne R. Moorewrote about the Moore family firm, the Moore Special Tool Company, who independently invented thejig borer(contemporaneously with its Swiss invention). Moore's monograph,Foundations of Mechanical Accuracy,[9]is a seminal classic of the principles of machine tool design and construction that yield the highest possibleaccuracy and precisionin machine tools (second only to that ofmetrologicalmachines). The Moore firm epitomized the art and science of thetool and die maker.

David F. Noble'sForces of Production(1984)[10]is one of the most detailed histories of the machine tool industry from World War II through the early 1980s, relayed in the context of the social impact of evolving automation via NC and CNC. Also in 1984,David A. HounshellpublishedFrom the American System to Mass Production,[11]one of the most detailed histories of the machine tool industry from the late 18th century through 1932. It does not concentrate on listing firm names and sales statistics (which Floud's 1976 monograph[12]focuses on) but rather is extremely detailed in exploring the development and spread of practicable interchangeability, and the thinking behind the intermediate steps. It is extensively cited by later works.

In 1989, Holland published a history,When the Machine Stopped,[3]that is most specifically about Burgmaster (which specialized in turret drills); but in telling Burgmaster's story, and that of its acquirerHoudaille,Holland provides a history of the machine tool industry in general between World War II and the 1980s that ranks with Noble's coverage of the same era (Noble 1984)[10]as a seminal history. It was later republished under the titleFrom Industry to Alchemy.

See also

[edit]References

[edit]Bibliography

[edit]- Colvin, Fred H.(1947),Sixty Years with Men and Machines,New York and London: McGraw-Hill,LCCN47003762.Available as a reprint from Lindsay Publications (ISBN978-0-917914-86-7). Foreword byRalph Flanders.

- Floud, Roderick C. (2006) [1976],The British Machine Tool Industry, 1850-1914,Cambridge, England: Cambridge University Press,ISBN978-0-521-02555-3,LCCN2006275684,OCLC70251252.

- Holland, Max(1989),When the Machine Stopped: A Cautionary Tale from Industrial America,Boston: Harvard Business School Press,ISBN978-0-87584-208-0,OCLC246343673.

- Hounshell, David A.(1984),From the American System to Mass Production, 1800–1932: The Development of Manufacturing Technology in the United States,Baltimore, Maryland:Johns Hopkins University Press,ISBN978-0-8018-2975-8,LCCN83016269,OCLC1104810110

- Moore, Wayne R.(1970),Foundations of Mechanical Accuracy(1st ed.), Bridgeport, Connecticut, US: Moore Special Tool Co.,LCCN73127307.

- Noble, David F.(1984),Forces of Production: A Social History of Industrial Automation,New York, New York, US: Knopf,ISBN978-0-394-51262-4,LCCN83048867.

- Roe, Joseph Wickham(1916),English and American Tool Builders,New Haven, Connecticut: Yale University Press,LCCN16011753.Reprinted by McGraw-Hill, New York and London, 1926 (LCCN27-24075); and by Lindsay Publications, Inc., Bradley, Illinois (ISBN978-0-917914-73-7).

- Roe, Joseph Wickham (1937),James Hartness: A Representative of the Machine Age at Its Best,New York:American Society of Mechanical Engineers,LCCN37016470,OCLC3456642.link fromHathiTrust.

- Rolt, L. T. C.(1965),A Short History of Machine Tools,Cambridge, Massachusetts, USA: MIT Press,OCLC250074.Co-edition published asRolt, L. T. C. (1965),Tools for the Job: a Short History of Machine Tools,London: B. T. Batsford,LCCN65080822.

- Rose, William (1990),Cleveland: the making of a city,Kent State University Press,ISBN978-0-87338-428-5

- Jerome, Harry (1934),"Mechanization in Industry",NBER,Cambridge, Massachusetts, US: US National Bureau of Economic Research.

- Ryder, Thomas and Son,Machines to Make Machines 1865 to 1968,a centenary booklet, (Derby: Bemrose & Sons, 1968)

- Woodbury, Robert S. (1972),Studies in the History of Machine Tools,Cambridge, Massachusetts, US, and London, England: MIT Press,ISBN978-0-262-73033-4,LCCN72006354