Steel

| Steels |

|---|

|

| Phases |

| Microstructures |

| Classes |

| Other iron-based materials |

Steelis analloyofironandcarbonwith improvedstrengthandfracture resistancecompared to other forms of iron. Because of its hightensile strengthand low cost, steel is one of the most commonly manufactured materials in the world. Steel is used in buildings, as concrete reinforcing rods, in bridges, infrastructure, tools, ships, trains, cars, bicycles, machines, electrical appliances, furniture, and weapons.

Iron is always the main element in steel, but many other elements may be present or added.Stainless steels,which are resistant tocorrosionandoxidation,typically need an additional 11%chromium.

Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms):body-centred cubic and face-centred cubic.The interaction of theallotropes of ironwith the alloying elements, primarily carbon, gives steel andcast irontheir range of unique properties. In pure iron, thecrystal structurehas relatively little resistance to the iron atoms slipping past one another, and so pure iron is quiteductile,or soft and easily formed. In steel, small amounts of carbon, other elements, and inclusions within the iron act as hardening agents that prevent the movement ofdislocations.

The carbon in typical steel alloys may contribute up to 2.14% of its weight. Varying the amount of carbon and many other alloying elements, as well as controlling their chemical and physical makeup in the final steel (either as solute elements, or as precipitated phases), impedes the movement of the dislocations that make pure iron ductile, and thus controls and enhances its qualities. These qualities include thehardness,quenching behaviour,need forannealing,tempering behaviour,yield strength,and tensile strength of the resulting steel. The increase in steel's strength compared to pure iron is possible only by reducing iron's ductility.

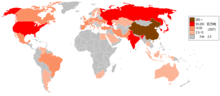

Steel was produced inbloomeryfurnaces for thousands of years, but its large-scale, industrial use began only after more efficient production methods were devised in the 17th century, with the introduction of theblast furnaceand production ofcrucible steel.This was followed by theBessemer processinEnglandin the mid-19th century, and then by theopen-hearth furnace.With the invention of the Bessemer process, a new era ofmass-producedsteel began.Mild steelreplacedwrought iron.The German stateswere the major steel producers in Europe in the 19th century.[1]American steel production was centred inPittsburgh,Bethlehem, Pennsylvania,andClevelanduntil the late 20th century. Currently,world steel productionis centered in China, which produced 54% of the world's steel in 2023.

Further refinements in the process, such asbasic oxygen steelmaking(BOS), largely replaced earlier methods by further lowering the cost of production and increasing the quality of the final product. Today more than 1.6 billion tons of steel is produced annually. Modern steel is generally identified by various grades defined by assortedstandards organizations.The modern steel industry is one of the largest manufacturing industries in the world, but also one of the most energy andgreenhouse gas emissionintense industries, contributing 8% of global emissions.[2]However, steel is also very reusable: it is one of the world's most-recycled materials, with arecycling rate of over 60% globally.[3]

Definitions and related materials

[edit]

The nounsteeloriginates from theProto-Germanicadjective **stahlijąor **stakhlijan'made of steel', which is related to **stahlazor **stahliją'standing firm'.[4]

The carbon content of steel is between 0.02% and 2.14% by weight for plain carbon steel (iron-carbonalloys). Too little carbon content leaves (pure) iron quite soft, ductile, and weak. Carbon contents higher than those of steel make a brittle alloy commonly calledpig iron.Alloy steelis steel to which other alloying elements have been intentionally added to modify the characteristics of steel. Common alloying elements include:manganese,nickel,chromium,molybdenum,boron,titanium,vanadium,tungsten,cobalt,andniobium.[5]Additional elements, most frequently considered undesirable, are also important in steel:phosphorus,sulphur,silicon,and traces ofoxygen,nitrogen,andcopper.

Plain carbon-iron alloys with a higher than 2.1% carbon content are known ascast iron.With modernsteelmakingtechniques such as powder metal forming, it is possible to make very high-carbon (and other alloy material) steels, but such are not common. Cast iron is not malleable even when hot, but it can be formed bycastingas it has a lowermelting pointthan steel and goodcastabilityproperties.[5]Certain compositions of cast iron, while retaining the economies of melting and casting, can be heat treated after casting to makemalleable ironorductile ironobjects. Steel is distinguishable fromwrought iron(now largely obsolete), which may contain a small amount of carbon but large amounts ofslag.

Material properties

[edit]Origins and production

[edit]

Iron is commonly found in the Earth'scrustin the form of anore,usually an iron oxide, such asmagnetiteorhematite.Iron is extracted fromiron oreby removing the oxygen through its combination with a preferred chemical partner such as carbon which is then lost to the atmosphere as carbon dioxide. This process, known assmelting,was first applied to metals with lowermeltingpoints, such astin,which melts at about 250 °C (482 °F), andcopper,which melts at about 1,100 °C (2,010 °F), and the combination, bronze, which has a melting point lower than 1,083 °C (1,981 °F). In comparison, cast iron melts at about 1,375 °C (2,507 °F).[6]Small quantities of iron were smelted in ancient times, in the solid-state, by heating the ore in acharcoalfire and thenweldingthe clumps together with a hammer and in the process squeezing out the impurities. With care, the carbon content could be controlled by moving it around in the fire. Unlike copper and tin, liquid or solid iron dissolves carbon quite readily.[citation needed]

All of these temperatures could be reached with ancient methods used since theBronze Age.Since the oxidation rate of iron increases rapidly beyond 800 °C (1,470 °F), it is important that smelting take place in a low-oxygen environment. Smelting, using carbon to reduce iron oxides, results in an alloy (pig iron) that retains too much carbon to be called steel.[6]The excess carbon and other impurities are removed in a subsequent step.[citation needed]

Other materials are often added to the iron/carbon mixture to produce steel with the desired properties.Nickelandmanganesein steel add to its tensile strength and make theausteniteform of the iron-carbon solution more stable,chromiumincreases hardness and melting temperature, andvanadiumalso increases hardness while making it less prone tometal fatigue.[7]

To inhibit corrosion, at least 11% chromium can be added to steel so that a hardoxideforms on the metal surface; this is known asstainless steel.Tungsten slows the formation ofcementite,keeping carbon in the iron matrix and allowingmartensiteto preferentially form at slower quench rates, resulting inhigh-speed steel.The addition ofleadandsulphurdecrease grain size, thereby making the steel easier toturn,but also more brittle and prone to corrosion. Such alloys are nevertheless frequently used for components such as nuts, bolts, and washers in applications where toughness and corrosion resistance are not paramount. For the most part, however,p-blockelements such as sulphur,nitrogen,phosphorus,and lead are considered contaminants that make steel more brittle and are therefore removed from steel during the melting processing.[7]

Properties

[edit]

Thedensityof steel varies based on the alloying constituents but usually ranges between 7,750 and 8,050 kg/m3(484 and 503 lb/cu ft), or 7.75 and 8.05 g/cm3(4.48 and 4.65 oz/cu in).[8]

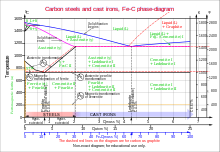

Even in a narrow range of concentrations of mixtures of carbon and iron that make steel, several different metallurgical structures, with very different properties can form. Understanding such properties is essential to making quality steel. Atroom temperature,the most stable form of pure iron is thebody-centred cubic(BCC) structure called alpha iron or α-iron. It is a fairly soft metal that can dissolve only a small concentration of carbon, no more than 0.005% at 0 °C (32 °F) and 0.021 wt% at 723 °C (1,333 °F). The inclusion of carbon in alpha iron is calledferrite.At 910 °C, pure iron transforms into aface-centred cubic(FCC) structure, called gamma iron or γ-iron. The inclusion of carbon in gamma iron is called austenite. The more open FCC structure of austenite can dissolve considerably more carbon, as much as 2.1%,[9](38 times that of ferrite) carbon at 1,148 °C (2,098 °F), which reflects the upper carbon content of steel, beyond which is cast iron.[10]When carbon moves out of solution with iron, it forms a very hard, but brittle material called cementite (Fe3C).[citation needed]

When steels with exactly 0.8% carbon (known as a eutectoid steel), are cooled, theausteniticphase (FCC) of the mixture attempts to revert to the ferrite phase (BCC). The carbon no longer fits within the FCC austenite structure, resulting in an excess of carbon. One way for carbon to leave the austenite is for it toprecipitateout of solution ascementite,leaving behind a surrounding phase of BCC iron called ferrite with a small percentage of carbon in solution. The two, cementite and ferrite, precipitate simultaneously producing a layered structure calledpearlite,named for its resemblance tomother of pearl.In a hypereutectoid composition (greater than 0.8% carbon), the carbon will first precipitate out as large inclusions of cementite at the austenitegrain boundariesuntil the percentage of carbon in thegrainshas decreased to the eutectoid composition (0.8% carbon), at which point the pearlite structure forms. For steels that have less than 0.8% carbon (hypoeutectoid), ferrite will first form within the grains until the remaining composition rises to 0.8% of carbon, at which point the pearlite structure will form. No large inclusions of cementite will form at the boundaries in hypoeutectoid steel.[11]The above assumes that the cooling process is very slow, allowing enough time for the carbon to migrate.[citation needed]

As the rate of cooling is increased the carbon will have less time to migrate to form carbide at the grain boundaries but will have increasingly large amounts of pearlite of a finer and finer structure within the grains; hence the carbide is more widely dispersed and acts to prevent slip of defects within those grains, resulting in hardening of the steel. At the very high cooling rates produced by quenching, the carbon has no time to migrate but is locked within the face-centred austenite and formsmartensite.Martensite is a highly strained and stressed, supersaturated form of carbon and iron and is exceedingly hard but brittle. Depending on the carbon content, the martensitic phase takes different forms. Below 0.2% carbon, it takes on a ferrite BCC crystal form, but at higher carbon content it takes abody-centred tetragonal(BCT) structure. There is no thermalactivation energyfor the transformation from austenite to martensite.[clarification needed]There is no compositional change so the atoms generally retain their same neighbours.[12]

Martensite has a lower density (it expands during the cooling) than does austenite, so that the transformation between them results in a change of volume. In this case, expansion occurs. Internal stresses from this expansion generally take the form ofcompressionon the crystals of martensite andtensionon the remaining ferrite, with a fair amount ofshearon both constituents. If quenching is done improperly, the internal stresses can cause a part to shatter as it cools. At the very least, they cause internalwork hardeningand other microscopic imperfections. It is common for quench cracks to form when steel is water quenched, although they may not always be visible.[13]

Heat treatment

[edit]There are many types ofheat treatingprocesses available to steel. The most common areannealing,quenching,andtempering.

Annealing is the process of heating the steel to a sufficiently high temperature to relieve local internal stresses. It does not create a general softening of the product but only locally relieves strains and stresses locked up within the material. Annealing goes through three phases:recovery,recrystallization,andgrain growth.The temperature required to anneal a particular steel depends on the type of annealing to be achieved and the alloying constituents.[14]

Quenching involves heating the steel to create the austenite phase then quenching it in water oroil.This rapid cooling results in a hard but brittle martensitic structure.[12]The steel is then tempered, which is just a specialized type of annealing, to reduce brittleness. In this application the annealing (tempering) process transforms some of the martensite into cementite, orspheroiditeand hence it reduces the internal stresses and defects. The result is a more ductile and fracture-resistant steel.[15]

Production

[edit]

When iron issmeltedfrom its ore, it contains more carbon than is desirable. To become steel, it must be reprocessed to reduce the carbon to the correct amount, at which point other elements can be added. In the past, steel facilities wouldcastthe raw steel product intoingotswhich would be stored until use in further refinement processes that resulted in the finished product. In modern facilities, the initial product is close to the final composition and iscontinuously castinto long slabs, cut and shaped into bars and extrusions and heat treated to produce a final product. Today, approximately 96% of steel is continuously cast, while only 4% is produced as ingots.[16]

The ingots are then heated in a soaking pit andhot rolledinto slabs,billets,orblooms.Slabs are hot orcold rolledintosheet metalor plates. Billets are hot or cold rolled into bars, rods, and wire. Blooms are hot or cold rolled intostructural steel,such asI-beamsandrails.In modern steel mills these processes often occur in oneassembly line,with ore coming in and finished steel products coming out.[17]Sometimes after a steel's final rolling, it is heat treated for strength; however, this is relatively rare.[18]

History

[edit]Ancient

[edit]

Steel was known in antiquity and was produced inbloomeriesandcrucibles.[19][20]

The earliest known production of steel is seen in pieces of ironware excavated from anarchaeological siteinAnatolia(Kaman-Kalehöyük) which are nearly 4,000 years old, dating from 1800 BC.[21][22]

Wootz steelwas developed inSouthern IndiaandSri Lankain the 1st millennium BC.[20]Metal production sites inSri Lankaemployed wind furnaces driven by the monsoon winds, capable of producing high-carbon steel. Large-scale wootz steel production inIndiausing crucibles occurred by the sixth century BC, the pioneering precursor to modern steel production and metallurgy.[19][20]

High-carbon steel was produced inBritainatBroxmouth Hillfortfrom 490–375 BC,[23][24]and ultrahigh-carbon steel was produced in theNetherlandsfrom the 2nd-4th centuries AD.[25]The Roman authorHoraceidentifies steel weapons such as thefalcatain theIberian Peninsula,whileNoric steelwas used by theRoman military.[26]

TheChineseof theWarring States period(403–221 BC) hadquench-hardenedsteel,[27]while Chinese of theHan dynasty(202 BC—AD 220) created steel by melting together wrought iron with cast iron, thus producing a carbon-intermediate steel by the 1st century AD.[28][29]

There is evidence thatcarbon steelwas made in WesternTanzaniaby the ancestors of theHaya peopleas early as 2,000 years ago by a complex process of "pre-heating" allowing temperatures inside a furnace to reach 1300 to 1400 °C.[30][31][32][33][34][35]

Wootz and Damascus

[edit]Evidence of the earliest production of high carbon steel inSouth Asiais found inKodumanalinTamil Nadu,theGolcondaarea inAndhra PradeshandKarnataka,regions ofIndia,as well as inSamanalawewaand Dehigaha Alakanda, regions ofSri Lanka.[36]This came to be known aswootz steel,produced in South India by about the sixth century BC and exported globally.[37][38]The steel technology existed prior to 326 BC in the region as they are mentioned in literature ofSangam Tamil,Arabic, and Latin as the finest steel in the world exported to the Roman, Egyptian, Chinese and Arab worlds at that time – what they calledSeric Iron.[39]A200 BC Tamil trade guild in Tissamaharama,in the South East of Sri Lanka, brought with them some of the oldest iron and steel artifacts and production processes to the island from theclassical period.[40][41][42]The Chinese and locals inAnuradhapura,Sri Lanka had also adopted the production methods of creating wootz steel from theChera DynastyTamils of South India by the 5th century AD.[43][44]In Sri Lanka, this early steel-making method employed a unique wind furnace, driven by the monsoon winds, capable of producing high-carbon steel.[45][46]Since the technology was acquired from theTamiliansfrom South India,[47]the origin of steel technology in India can be conservatively estimated at 400–500 BC.[37][46]

The manufacture ofwootz steelandDamascus steel,famous for its durability and ability to hold an edge, may have been taken by the Arabs from Persia, who took it from India.It was originally created from several different materials including varioustrace elements,apparently ultimately from the writings ofZosimos of Panopolis.[citation needed]In 327 BC,Alexander the Greatwas rewarded by the defeated KingPorus,not with gold or silver but with 30 pounds of steel.[48]A recent study has speculated thatcarbon nanotubeswere included in its structure, which might explain some of its legendary qualities, though, given the technology of that time, such qualities were produced by chance rather than by design.[49]Natural wind was used where the soil containing iron was heated by the use of wood. Theancient Sinhalesemanaged to extract a ton of steel for every 2 tons of soil,[45]a remarkable feat at the time. One such furnace was found in Samanalawewa and archaeologists were able to produce steel as the ancients did.[45][50]

Crucible steel,formed by slowly heating and cooling pure iron and carbon (typically in the form of charcoal) in a crucible, was produced inMervby the 9th to 10th century AD.[38]In the 11th century, there is evidence of the production of steel inSong Chinausing two techniques: a "berganesque" method that produced inferior, inhomogeneous steel, and a precursor to the modernBessemer processthat used partialdecarburizationvia repeated forging under acold blast.[51]

Modern

[edit]

Since the 17th century, the first step in European steel production has been the smelting of iron ore intopig ironin ablast furnace.[52][page needed]Originally employing charcoal, modern methods usecoke,which has proven more economical.[53][page needed][54][page needed][55][page needed]

Processes starting from bar iron

[edit]In these processes,pig ironmade from raw iron ore was refined (fined) in afinery forgeto producebar iron,which was then used in steel-making.[52]

The production of steel by thecementation processwas described in a treatise published in Prague in 1574 and was in use inNurembergfrom 1601. A similar process forcase hardeningarmour and files was described in a book published inNaplesin 1589. The process was introduced to England in about 1614 and used to produce such steel by SirBasil BrookeatCoalbrookdaleduring the 1610s.[56]

The raw material for this process were bars of iron. During the 17th century, it was realized that the best steel came fromoregrounds ironof a region north ofStockholm,Sweden. This was still the usual raw material source in the 19th century, almost as long as the process was used.[57][58]

Crucible steel is steel that has been melted in acruciblerather than having beenforged,with the result that it is more homogeneous. Most previous furnaces could not reach high enough temperatures to melt the steel. The early modern crucible steel industry resulted from the invention ofBenjamin Huntsmanin the 1740s. Blister steel (made as above) was melted in a crucible or in a furnace, and cast (usually) into ingots.[58][59][page needed]

Processes starting from pig iron

[edit]

The modern era insteelmakingbegan with the introduction ofHenry Bessemer'sprocessin 1855, the raw material for which was pig iron.[60]His method let him produce steel in large quantities cheaply, thusmild steelcame to be used for most purposes for which wrought iron was formerly used.[61]The Gilchrist-Thomas process (orbasic Bessemer process) was an improvement to the Bessemer process, made by lining the converter with abasicmaterial to remove phosphorus.

Another 19th-century steelmaking process was theSiemens-Martin process,which complemented the Bessemer process.[58]It consisted of co-melting bar iron (or steel scrap) with pig iron.

These methods of steel production were rendered obsolete by the Linz-Donawitz process ofbasic oxygen steelmaking(BOS), developed in 1952,[62]and other oxygen steel making methods. Basic oxygen steelmaking is superior to previous steelmaking methods because the oxygen pumped into the furnace limited impurities, primarily nitrogen, that previously had entered from the air used,[63]and because, with respect to the open hearth process, the same quantity of steel from a BOS process is manufactured in one-twelfth the time.[62]Today,electric arc furnaces(EAF) are a common method of reprocessingscrap metalto create new steel. They can also be used for converting pig iron to steel, but they use a lot of electrical energy (about 440 kWh per metric ton), and are thus generally only economical when there is a plentiful supply of cheap electricity.[64]

Industry

[edit]

The steel industry is often considered an indicator of economic progress, because of the critical role played by steel in infrastructural and overalleconomic development.[65]In 1980, there were more than 500,000 U.S. steelworkers. By 2000, the number of steelworkers had fallen to 224,000.[66]

Theeconomic boomin China and India caused a massive increase in the demand for steel. Between 2000 and 2005, world steel demand increased by 6%. Since 2000, several Indian[67]and Chinese[68]steel firms have expanded to meet demand, such asTata Steel(which boughtCorus Groupin 2007),Baosteel GroupandShagang Group.As of 2017[update],though,ArcelorMittalis the world'slargest steel producer.[69]

In 2005, theBritish Geological SurveystatedChinawas the top steel producer with about one-third of the world share;Japan,Russia,and theUnited Stateswere second, third, and fourth, respectively, according to the survey.[70]The large production capacity of steel results also in a significant amount of carbon dioxide emissions inherent related to the main production route.

At the end of 2008, the steel industry faced a sharp downturn that led to many cut-backs.[71]

In 2021, it was estimated that around 7% of the global greenhouse gas emissions resulted from the steel industry.[72][73]Reduction of these emissions are expected to come from a shift in the main production route using cokes, more recycling of steel and the application ofcarbon capture and storagetechnology.

Recycling

[edit]Steel is one of the world's most-recycled materials, with arecycling rateof over 60% globally;[3]in the United States alone, over 82,000,000 metric tons (81,000,000 long tons; 90,000,000 short tons) were recycled in the year 2008, for an overall recycling rate of 83%.[74]

As more steel is produced than is scrapped, the amount of recycled raw materials is about 40% of the total of steel produced - in 2016, 1,628,000,000 tonnes (1.602×109long tons; 1.795×109short tons) of crude steel was produced globally, with 630,000,000 tonnes (620,000,000 long tons; 690,000,000 short tons) recycled.[75]

Contemporary

[edit]

Carbon

[edit]Modern steels are made with varying combinations of alloy metals to fulfil many purposes.[7]Carbon steel,composed simply of iron and carbon, accounts for 90% of steel production.[5]Low alloy steelis alloyed with other elements, usuallymolybdenum,manganese, chromium, or nickel, in amounts of up to 10% by weight to improve the hardenability of thick sections.[5]High strength low alloy steelhas small additions (usually < 2% by weight) of other elements, typically 1.5% manganese, to provide additional strength for a modest price increase.[76]

Recentcorporate average fuel economy(CAFE) regulations have given rise to a new variety of steel known as Advanced High Strength Steel (AHSS). This material is both strong and ductile so that vehicle structures can maintain their current safety levels while using less material. There are several commercially available grades of AHSS, such asdual-phase steel,which is heat treated to contain both a ferritic and martensitic microstructure to produce a formable, high strength steel.[77]Transformation Induced Plasticity (TRIP) steel involves special alloying and heat treatments to stabilize amounts ofausteniteat room temperature in normally austenite-free low-alloy ferritic steels. By applying strain, the austenite undergoes aphase transitionto martensite without the addition of heat.[78]Twinning Induced Plasticity (TWIP) steel uses a specific type of strain to increase the effectiveness of work hardening on the alloy.[79]

Carbon Steels are oftengalvanized,through hot-dip or electroplating inzincfor protection against rust.[80]

Alloy

[edit]

Stainless steelcontains a minimum of 11% chromium, often combined with nickel, to resistcorrosion.Some stainless steels, such as theferriticstainless steels aremagnetic,while others, such as theaustenitic,are nonmagnetic.[81]Corrosion-resistant steels are abbreviated as CRES.

Alloy steels are plain-carbon steels in which small amounts of alloying elements like chromium and vanadium have been added. Some more modern steels includetool steels,which are alloyed with large amounts of tungsten andcobaltor other elements to maximizesolution hardening.This also allows the use ofprecipitation hardeningand improves the alloy's temperature resistance.[5]Tool steel is generally used in axes, drills, and other devices that need a sharp, long-lasting cutting edge. Other special-purpose alloys includeweathering steelssuch as Cor-ten, which weather by acquiring a stable, rusted surface, and so can be used un-painted.[82]Maraging steelis alloyed with nickel and other elements, but unlike most steel contains little carbon (0.01%). This creates a very strong but stillmalleablesteel.[83]

Eglin steeluses a combination of over a dozen different elements in varying amounts to create a relatively low-cost steel for use inbunker busterweapons.Hadfield steel,named afterRobert Hadfield,or manganese steel, contains 12–14% manganese which, when abraded, strain-hardens to form a very hard skin which resists wearing. Uses of this particular alloy includetank tracks,bulldozer bladeedges, and cutting blades on thejaws of life.[84]

Standards

[edit]Most of the more commonly used steel alloys are categorized into various grades by standards organizations. For example, theSociety of Automotive Engineershas a series ofgradesdefining many types of steel.[85]TheAmerican Society for Testing and Materialshas a separate set of standards, which define alloys such asA36 steel,the most commonly used structural steel in the United States.[86]TheJISalso defines a series of steel grades that are being used extensively in Japan as well as in developing countries.

Uses

[edit]

Iron and steel are used widely in the construction of roads, railways, other infrastructure, appliances, and buildings. Most large modern structures, such asstadiumsand skyscrapers, bridges, and airports, are supported by a steel skeleton. Even those with a concrete structure employ steel for reinforcing. It sees widespread use inmajor appliancesandcars.Despite the growth in usage ofaluminium,steel is still the main material for car bodies. Steel is used in a variety of other construction materials, such as bolts,nailsandscrews,and other household products and cooking utensils.[87]

Other common applications includeshipbuilding,pipelines,mining,offshore construction,aerospace,white goods(e.g.washing machines),heavy equipmentsuch as bulldozers, office furniture,steel wool,tool,andarmourin the form of personal vests orvehicle armour(better known asrolled homogeneous armourin this role).

Historical

[edit]

Before the introduction of theBessemer processand other modern production techniques, steel was expensive and was only used where no cheaper alternative existed, particularly for the cutting edge ofknives,razors,swords,and other items where a hard, sharp edge was needed. It was also used forsprings,including those used inclocks and watches.[58]

With the advent of faster and cheaper production methods, steel has become easier to obtain and much cheaper. It has replaced wrought iron for a multitude of purposes. However, the availability of plastics in the latter part of the 20th century allowed these materials to replace steel in some applications due to their lower fabrication cost and weight.[88]Carbon fibreis replacing steel in some cost-insensitive applications such as sports equipment and high-end automobiles.

Long

[edit]

- As reinforcing bars and mesh inreinforced concrete

- Railroad tracks

- Structural steelin modern buildings and bridges

- Wires

- Input to reforging applications

Flat carbon

[edit]- Major appliances

- Magnetic cores

- The inside and outside body of automobiles, trains, and ships.

Weathering (COR-TEN)

[edit]- Intermodal containers

- Outdoor sculptures

- Architecture

- Highlinertrain cars

Stainless

[edit]

- Cutlery

- Rulers

- Surgical instruments

- Watches

- Guns

- Rail passenger vehicles

- Tablets

- Trash Cans

- Body piercing jewellery

- Inexpensiverings

- Components ofspacecraftandspace stations

Low-background

[edit]Steel manufactured afterWorld War IIbecamecontaminatedwithradionuclidesbynuclear weapons testing.Low-background steel, steel manufactured prior to 1945, is used for certain radiation-sensitive applications such asGeiger countersandradiation shielding.

See also

[edit]- Bulat steel

- Direct reduction

- Carbon steel

- Damascus steel

- Galvanizing

- History of the steel industry (1970–present)

- Iron in folklore

- List of blade materials

- Machinability

- Noric steel

- Pelletizing

- Rolling

- Rolling mill

- Rust Belt

- Second Industrial Revolution

- Silicon steel

- Steel abrasive

- Steel mill

- Tamahagane,used in Japanese swords

- Tinplate

- Toledo steel

- Wootz steel

References

[edit]- ^Allen, Robert C. (December 1979). "International Competition in Iron and Steel, 1850–1913".The Journal of Economic History.39(4).Cambridge University Press:911–937.doi:10.1017/S0022050700098673.JSTOR2120336.

- ^"Decarbonization in steel | McKinsey".McKinsey.com.Retrieved20 May2022.

- ^abHartman, Roy A. (2009)."Recycling".Encarta.Archived fromthe originalon 14 April 2008.

- ^Harper, Douglas."steel".Online Etymology Dictionary.

- ^abcdeAshby, Michael F. & Jones, David R.H. (1992) [1986].Engineering Materials 2(with corrections ed.). Oxford: Pergamon Press.ISBN0-08-032532-7.

- ^ab"Smelting".Encyclopædia Britannica(online ed.). 2007.

- ^abc"Alloying of Steels".Metallurgical Consultants. 28 June 2006. Archived fromthe originalon 21 February 2007.Retrieved28 February2007.

- ^Elert, Glenn."Density of Steel".Retrieved23 April2009.

- ^Sources differ on this value so it has been rounded to 2.1%, however the exact value is rather academic because plain-carbon steel is very rarely made with this level of carbon. See:

- Smith & Hashemi 2006,p. 363—2.08%.

- Degarmo, Black & Kohser 2003,p. 75—2.11%.

- Ashby & Jones 1992—2.14%.

- ^Smith & Hashemi 2006,p. 363.

- ^Smith & Hashemi 2006,pp. 365–372.

- ^abSmith & Hashemi 2006,pp. 373–378.

- ^"Quench hardening of steel".keytometals.com.Archived fromthe originalon 17 February 2009.Retrieved19 July2009.

- ^Smith & Hashemi 2006,p. 249.

- ^Smith & Hashemi 2006,p. 388.

- ^Smith & Hashemi 2006,p. 361

- ^Smith & Hashemi 2006,pp. 361–362.

- ^Bugayev et al. 2001,p. 225

- ^abDavidson (1994),p. 20.

- ^abcSrinivasan, S.; Ranganathan, S. (1994)."The Sword in Anglo-Saxon England: Its Archaeology and Literature".Bangalore: Department of Metallurgy, Indian Institute of Science.ISBN0-85115-355-0.Archived fromthe originalon 19 November 2018.

- ^Akanuma, H. (2005). "The significance of the composition of excavated iron fragments taken from Stratum III at the site of Kaman-Kalehöyük, Turkey".Anatolian Archaeological Studies.14.Tokyo: Japanese Institute of Anatolian Archaeology: 147–158.

- ^"Ironware piece unearthed from Turkey found to be oldest steel".The Hindu.Chennai. 26 March 2009. Archived fromthe originalon 29 March 2009.Retrieved13 August2022.

- ^"East Lothian's Broxmouth fort reveals edge of steel".BBC News.15 January 2014.

- ^An Inherited Place: Broxmouth Hillfort and the South-East Scottish Iron Age.Society of Antiquaries of Scotland. 2013.ISBN978-1-908332-05-9.

- ^Godfrey, Evelyne; et al. (2004)."A Germanic ultrahigh carbon steel punch of the Late Roman-Iron Age".Journal of Archaeological Science.31(8): 1117–1125.Bibcode:2004JArSc..31.1117G.doi:10.1016/j.jas.2004.02.002.

- ^"Noricus ensis",Horace,Odes, i. 16.9

- ^Wagner, Donald B. (1993).Iron and Steel in Ancient China(2nd ed.). Leiden: E. J. Brill. p. 243.ISBN90-04-09632-9.

- ^Needham, Joseph (1986).Science and Civilization in China: Volume 4, Part 3, Civil Engineering and Nautics.Taipei: Caves Books. p. 563.

- ^Gernet, Jacques (1982).A History of Chinese Civilization.Cambridge: Cambridge University Press. p. 69.ISBN0-521-49781-7.

- ^Schmidt, Peter; Avery, Donald (1978). "Complex Iron Smelting and Prehistoric Culture in Tanzania".Science.201(4361): 1085–1089.Bibcode:1978Sci...201.1085S.doi:10.1126/science.201.4361.1085.JSTOR1746308.PMID17830304.S2CID37926350.

- ^Schmidt, Peter; Avery, Donald (1983). "More Evidence for an Advanced Prehistoric Iron Technology in Africa".Journal of Field Archaeology.10(4): 421–434.doi:10.1179/009346983791504228.

- ^Schmidt, Peter (1978).Historical Archaeology: A Structural Approach in an African Culture.Westport, Connecticut: Greenwood Press.

- ^Avery, Donald; Schmidt, Peter (1996). "Preheating: Practice or illusion".The Culture and Technology of African Iron Production.Gainesville, Florida: University of Florida Press. pp. 267–276.

- ^Schmidt, Peter (2019). "Science in Africa: A history of ingenuity and invention in African iron technology". In Worger, W.; Ambler, C.; Achebe, N. (eds.).A Companion to African History.Hoboken, New Jersey: Wiley Blackwell. pp. 267–288.

- ^Childs, S. Terry (1996). "Technological history and culture in western Tanzania". In Schmidt, P. (ed.).The Culture and Technology of African Iron Production.Gainesville, Florida: University of Florida Press.

- ^Wilford, John Noble (6 February 1996)."Ancient Smelter Used Wind To Make High-Grade Steel".The New York Times.

- ^abSrinivasan, Sharada; Ranganathan, Srinivasa (2004).India's Legendary Wootz Steel: An Advanced Material of the Ancient World.National Institute of Advanced Studies.OCLC82439861.Archived fromthe originalon 11 February 2019.Retrieved5 December2014.

- ^abFeuerbach, Ann (2005)."An investigation of the varied technology found in swords, sabres and blades from the Russian Northern Caucasus"(PDF).IAMS.25:27–43 (p. 29). Archived fromthe original(PDF)on 30 April 2011.

- ^Srinivasan, Sharada (1994)."Wootz crucible steel: a newly discovered production site in South India".Papers from the Institute of Archaeology.5:49–59.doi:10.5334/pia.60.

- ^Hobbies – Volume 68, Issue 5 – p. 45. Lightner Publishing Company (1963)

- ^Mahathevan, Iravatham (24 June 2010)."An epigraphic perspective on the antiquity of Tamil".The Hindu.Archived fromthe originalon 1 July 2010.Retrieved31 October2010.

- ^Ragupathy, P. (28 June 2010)."Tissamaharama potsherd evidences ordinary early Tamils among population".Tamilnet.Retrieved31 October2010.

- ^Needham, Joseph (1986).Science and Civilization in China: Volume 4, Part 1, Civil Engineering and Nautics(PDF).Taipei: Caves Books. p. 282.ISBN0-521-05802-3.Archived fromthe original(PDF)on 3 July 2017.Retrieved4 August2017.

- ^Manning, Charlotte Speir.Ancient and Mediæval India. Volume 2.ISBN978-0-543-92943-3.

- ^abcJuleff, G. (1996). "An ancient wind powered iron smelting technology in Sri Lanka".Nature.379(3): 60–63.Bibcode:1996Natur.379...60J.doi:10.1038/379060a0.S2CID205026185.

- ^abCoghlan, Herbert Henery. (1977).Notes on prehistoric and early iron in the Old World.Oxprint. pp. 99–100

- ^Manning, Charlotte Speir.Ancient and Medieval India. Volume 2.ISBN978-0-543-92943-3.

- ^Durant, Will (1942).The Story of Civilization, Our Oriental Heritage.Simon & Schuster. p. 529.ISBN0-671-54800-X.

- ^Sanderson, Katharine (15 November 2006)."Sharpest cut from nanotube sword".Nature News.doi:10.1038/news061113-11.S2CID136774602.

- ^Wayman, M. L.; Juleff, G. (1999). "Crucible Steelmaking in Sri Lanka".Historical Metallurgy.33(1): 26.

- ^Hartwell, Robert (1966). "Markets, Technology and the Structure of Enterprise in the Development of the Eleventh Century Chinese Iron and Steel Industry".Journal of Economic History.26:53–54.doi:10.1017/S0022050700061842.S2CID154556274.

- ^abTylecote, R. F. (1992).A History of Metallurgy(2nd ed.). London: Institute of Materials. pp. 95–99, 102–105.ISBN0-901462-88-8.

- ^Raistrick, A. (1953).A Dynasty of Ironfounders.

- ^Hyde, C. K. (1977).Technological Change and the British Iron Industry.Princeton University Press.

- ^Trinder, B. (2000).The Industrial Revolution in Shropshire(3rd ed.). Chichester: Phillimore.ISBN9781860771330.

- ^Barraclough (1984a),pp. 48–52.

- ^King, P. W. (2003). "The Cartel in Oregrounds Iron: trading in the raw material for steel during the eighteenth century".Journal of Industrial History.6(1): 25–49.

- ^abcd"Iron and steel industry".Encyclopædia Britannica.2007.

- ^Barraclough (1984b).

- ^Swank, James Moore (1892).History of the Manufacture of Iron in All Ages.Burt Franklin.ISBN0-8337-3463-6.

- ^"Bessemer process".Encyclopædia Britannica.Vol. 2 (online ed.). 2005. p. 168.

- ^abSherman, Zander (4 September 2019)."How my great-grandfather's Dofasco steel empire rose and fell, and his descendants with it".The Globe and Mail.

- ^"Basic oxygen process".Encyclopædia Britannica.2007.

- ^Fruehan & Wakelin (1998),pp. 48–52.

- ^"Steel Industry".Archived fromthe originalon 18 June 2009.Retrieved12 July2009.

- ^"Congressional Record V. 148, Pt. 4, April 11, 2002 to April 24, 2002".United States Government Printing Office.

- ^Chopra, Anuj (12 February 2007)."India's steel industry steps onto world stage".Cristian Science Monitor.Retrieved12 July2009.

- ^"Worldsteel | World crude steel output decreases by −2.8% in 2015".Archived fromthe originalon 2 February 2017.Retrieved26 December2016.

- ^"Top Steelmakers in 2017"(PDF).World Steel Association. Archived fromthe original(PDF)on 23 August 2018.Retrieved22 August2018.

- ^"Long-term planning needed to meet steel demand".The News.1 March 2008. Archived fromthe originalon 25 May 2024.Retrieved2 November2010.

- ^Uchitelle, Louis(1 January 2009)."Steel Industry, in Slump, Looks to Federal Stimulus".The New York Times.Retrieved19 July2009.

- ^Rossi, Marcello (4 August 2022)."The Race to Remake the $2.5 Trillion Steel Industry With Green Steel".Singularity Hub.Retrieved6 August2022.

- ^"Global Steel Industry's GHG Emissions".Global Efficiency Intelligence.6 January 2021.Retrieved6 August2022.

- ^Fenton, Michael D. (2008). "Iron and Steel Scrap". InUnited States Geological Survey(ed.).Minerals Yearbook 2008.Vol. 1: Metals and Minerals.United States Government Publishing Office.ISBN978-1-4113-3015-3.

- ^The World Steel Association (1 March 2018)."Steel and raw materials"(PDF).Archived fromthe original(PDF)on 9 August 2018.

- ^"High strength low alloy steels".SchoolScience.co.uk.Archived fromthe originalon 21 September 2020.Retrieved14 August2007.

- ^"Dual-phase steel".Intota Expert Knowledge Services. Archived fromthe originalon 25 May 2011.Retrieved1 March2007.

- ^Werner, Ewald."Transformation Induced Plasticity in low alloyed TRIP-steels and microstructure response to a complex stress history".Archived fromthe originalon 23 December 2007.Retrieved1 March2007.

- ^Mirko, Centi; Saliceti, Stefano."Transformation Induced Plasticity (TRIP), Twinning Induced Plasticity (TWIP) and Dual-Phase (DP) Steels".Tampere University of Technology. Archived fromthe originalon 7 March 2008.Retrieved1 March2007.

- ^"Galvanic protection".Encyclopædia Britannica.2007.

- ^"Steel Glossary".American Iron and Steel Institute.Retrieved30 July2006.

- ^"Steel Interchange".American Institute of Steel Construction. Archived fromthe originalon 22 December 2007.Retrieved28 February2007.

- ^"Properties of Maraging Steels".Archived fromthe originalon 25 February 2009.Retrieved19 July2009.

- ^Tweedale, Geoffrey, ed. (1987).Sheffield Steel and America: A Century of Commercial and Technological Independence.Cambridge University Press. pp. 57–62.

- ^Bringas, John E. (2004).Handbook of Comparative World Steel Standards: Third Edition(PDF)(3rd. ed.). ASTM International. p. 14.ISBN0-8031-3362-6.Archived fromthe original(PDF)on 27 January 2007.

- ^Steel Construction Manual, 8th Edition, second revised edition, American Institute of Steel Construction, 1986, ch. 1 pp. 1–5

- ^Ochshorn, Jonathan (11 June 2002)."Steel in 20th Century Architecture".Encyclopedia of Twentieth Century Architecture.Retrieved26 April2010.

- ^Venables, John D.; Girifalco, Louis A.; Patel, C. Kumar N.; McCullough, R. L.; Marchant, Roger Eric; Kukich, Diane S. (2007)."Materials science".Encyclopædia Britannica(online ed.).

Bibliography

[edit]- Ashby, Michael F.;Jones, David Rayner Hunkin (1992).An introduction to microstructures, processing and design.Butterworth-Heinemann.

- Barraclough, K. C. (1984).Steel before Bessemer.Vol. I, Blister Steel: The Birth of an Industry. London: Metals Society.

- Barraclough, K. C. (1984).Steel Before Bessemer.Vol. II, Crucible Steel: The Growth of Technology. London: Metals Society.

- Bugayev, K.; Konovalov, Y.; Bychkov, Y.; Tretyakov, E.; Savin, Ivan V. (2001).Iron and Steel Production.Minerva Group.ISBN978-0-89499-109-7.

- Davidson, H. R. Ellis (1994).The Sword in Anglo-Saxon England: Its Archaeology and Literature.Woodbridge, Suffolk: Boydell Press.ISBN0-85115-355-0.

- Degarmo, E. Paul; Black, J. T.; Kohser, Ronald A. (2003).Materials and Processes in Manufacturing(9th ed.). Wiley.ISBN0-471-65653-4.

- Fruehan, R. J.; Wakelin, David H. (1998).The Making, Shaping, and Treating of Steel(11th ed.). Pittsburgh: AISE Steel Foundation.ISBN0-930767-03-9.

- Smith, William F.; Hashemi, Javad (2006).Foundations of Materials Science and Engineering(4th ed.). McGraw-Hill.ISBN0-07-295358-6.

Further reading

[edit]- Reutter, Mark (2005).Making Steel: Sparrows Point and the Rise and Ruin of American Industrial Might.University of Illinois Press.ISBN978-0-252-07233-8.

- Burn, Duncan (1961).The Economic History of Steelmaking, 1867–1939: A Study in Competition.Cambridge University Press. Archived fromthe originalon 26 July 2012.

- Hasegawa, Harukiyu (1996).The Steel Industry in Japan: A Comparison with Britain.Routledge. Archived fromthe originalon 18 April 2012.

- Carr, J. C.; Taplin, W. (1962).History of the British Steel Industry.Harvard University Press. Archived fromthe originalon 29 July 2012.

- Scamehorn, H. Lee (1992).Mill & Mine: The CF&I in the Twentieth Century.University of Nebraska Press. Archived fromthe originalon 26 July 2012.

- Verein Deutscher Eisenhüttenleute, ed. (1992).Steel: A Handbook for Materials Research and Engineering.Vol. 1: Fundamentals. Berlin, Heidelberg / Düsseldorf: Springer-Verlag / Verlag Stahleisen.ISBN3-540-52968-3.

- Verein Deutscher Eisenhüttenleute, ed. (1993).Steel: A Handbook for Materials Research and Engineering.Vol. 2: Applications. Berlin, Heidelberg / Düsseldorf: Springer-Verlag / Verlag Stahleisen.ISBN3-540-54075-X.

- Verhoeven, John D. (2007).Metallurgy for the Non-Metallurgist.ASM International.ISBN9781615030569.

- Warren, Kenneth (2001).Big Steel: The First Century of the United States Steel Corporation, 1901–2001.University of Pittsburgh Press. Archived fromthe originalon 1 May 2010.

External links

[edit]- Official websiteof theWorld Steel Association(WorldSteel.org)

- SteelUniversity.org– online steel education resources, an initiative of World Steel Association

- MATDAT Database of Properties of Unalloyed, Low-Alloy and High-Alloy Steels– obtained from published results of materials testing