Zinc–carbon battery

Azinc–carbon battery(orcarbon zinc batteryin U.S. English)[1][2][3][4]is adry cellprimary batterythat providesdirect electric currentfrom theelectrochemical reactionbetweenzinc(Zn) andmanganese dioxide(MnO2) in the presence of anammonium chloride(NH4Cl) electrolyte.[5]It produces a voltage of about 1.5voltsbetween the zincanode,which is typically constructed as a cylindrical container for the battery cell, and acarbonrod surrounded by a compound with a higherStandard electrode potential(positive polarity), known as thecathode,that collects the current from the manganese dioxide electrode. The name "zinc-carbon" is slightly misleading as it implies that carbon is acting as the oxidizing agent rather than the manganese dioxide.

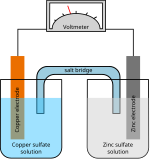

General-purpose batteries may use an acidic aqueous paste ofammonium chloride(NH4Cl) as electrolyte, with somezinc chloridesolution on a paper separator to act as what is known as asalt bridge.Heavy-dutytypes use a paste primarily composed ofzinc chloride(ZnCl2).

Zinc–carbon batteries were the first commercial dry batteries, developed from the technology of the wetLeclanché cell.They madeflashlightsand other portable devices possible, because the battery provided a higher energy density at a lower cost than previously available cells. They are still useful in low-drain or intermittent-use devices such asremote controls,flashlights, clocks ortransistor radios.Zinc–carbon dry cells are single-useprimary cells.Zinc-carbon batteries today have been mostly replaced by the more efficient and safealkaline batteries.

History[edit]

By 1876, the wetLeclanché cellwas made with a compressed block of manganese dioxide. In 1886,Carl Gassnerpatented a "dry" version by using a casing made of zinc sheet metal as theanodeand a paste ofplaster of Paris(and later,graphitepowder).[6]

In 1898,Conrad Hubertused consumer batteries manufactured by W. H. Lawrence to power what was the firstflashlight,and subsequently the two formed theEveready Battery Company.In 1900, Gassner demonstrated dry cells for portable lighting at theWorld's Fair in Paris.Continual improvements were made to the stability and capacity of zinc–carbon cells throughout the 20th century; by the end of the century the capacities had increased fourfold over the 1910 equivalent.[7]Improvements include the use of purer grades of manganese dioxide, the addition of graphite powder to the manganese dioxide to lowerinternal resistance,better sealing, and purer zinc for the negative electrode.Zinc-chloride cells(usually marketed as "heavy duty" batteries) use a higher concentration of anolyte (or anode electrolyte) which is primarily composed of zinc chloride, which can produce a more consistent voltage output in high drain applications.

Side reactions between impurities in the zinc metal/zinc chloride anode, and the ammonium chloride electrolyte can increase the self-discharge rate and promote corrosion of the cell.[5]Formerly, the zinc was coated withmercury(Hg) to form anamalgam,protecting it. Given that this is an environmental hazard, current production batteries no longer use mercury. Manufacturers must now use more highly purified zinc to prevent local action and self-discharge.[7]

As of 2011,[update]zinc–carbon batteries accounted for 20% of all portable batteries in the United Kingdom and 18% in the E.U.[8][9][10][11]

Construction[edit]

The container of the zinc–carbon dry cell is a zinc can (anode). The bottom and sides of the can contain a paper separator layer which is impregnated with ammonium chloride (NH4Cl) along with athickening agentto form an aqueous electrolyte paste. The paper separator prevents a short circuit from forming by protecting the zinc can from making contact with the cathode, which is a mixture of powdered carbon (usuallygraphitepowder) and manganese (IV) oxide (MnO2), which is packed around a carbon rod.[5]Carbon is the only practical conductor material because every common metal quicklycorrodesin the positive electrode when in the presence of a salt-based electrolyte.[citation needed]

Early types, and low-cost cells, use a separator consisting of a layer ofstarchorflour.A layer of starch-coated paper is used in modern cells, which is thinner and allows more manganese dioxide to be used. Originally cells were sealed with a layer ofasphaltto prevent drying out of the electrolyte; more recently, athermoplasticwasher seal is used to help preventleakageas well as to contain any internal pressure which may form as a result of hydrogen gas buildup during discharge. The carbon rod is slightly porous, which allows more chargedhydrogenatoms to combine forming hydrogen gas.[5]The ratio of manganese dioxide and carbon powder in the cathode paste affects the characteristics of the cell: more carbon powder lowersinternal resistance,while more manganese dioxide improves storage capacity.[7]

Flat cells are made for assembly into batteries with higher voltages, up to about 450 volts. Flat cells are stacked and the whole assembly is coated inwaxto prevent electrolyteevaporation.Electrons flow from the anode to cathode through the wire of the attached device.[12]

Uses[edit]

Zinc–carbon batteries have a lower per unit cost and are often used as power for appliances that consume little energy, likeremote controlsfor television, clocks, andsmoke detectors.Zinc-carbon batteries were in common use with hand-crankedtelephone magnetophones, powering the microphone and speaker.

Chemical reactions[edit]

In a zinc–carbon dry cell, the outer zinc container is the negatively charged terminal.

Ammonium chloride electrolyte[edit]

The zinc isoxidisedby thecharge carrier,chloride anion(Cl−) into ZnCl2,via the followinghalf-reactions:

Anode (oxidation reaction, marked −)

- Zn + 2 Cl−→ ZnCl2+ 2 e−

Cathode (reduction reaction, marked +)

- 2 MnO2+ 2 NH4Cl + H2O + 2 e−→ Mn2O3+ 2NH4OH+ 2 Cl−

Other side reactions are possible, but the overall reaction in a zinc–carbon cell can be represented as

- Zn + 2 MnO2+ 2 NH4Cl + H2O → ZnCl2+ Mn2O3+ 2 NH4OH

Zinc chloride electrolyte[edit]

Ifzinc chlorideis substituted forammonium chlorideas the electrolyte, the anode reaction remains the same:

- Zn + 2 Cl−→ ZnCl2+ 2 e−

and the cathode reaction produceszinc hydroxideandmanganese(III) oxide.

- 2 MnO2+ ZnCl2+ H2O + 2 e−→ Mn2O3+ Zn(OH)2+ 2 Cl−

giving the overall reaction

- Zn + 2 MnO2+ H2O → Mn2O3+ Zn(OH)2

The battery has anelectromotive force(e.m.f.) of about 1.5V.The approximate nature of the e.m.f is related to the complexity of the cathode reaction. The anode (zinc) reaction is comparatively simple with a known potential. Side reactions and depletion of the active chemicals increases theinternal resistanceof the battery, which causes the terminal voltage to drop under load.

Zinc-chloride "heavy duty" cell[edit]

The zinc-chloride cell, frequently referred to as aheavy-duty,extra-heavy-duty,super-heavy-duty,orsuper-extra-heavy-dutybattery, is an improvement on the original zinc–carbon cell, using purer chemicals and giving a longer service life and steadier voltage output as it is used and offering about twice the service life of general-purpose zinc–carbon cells, or up to four times in continuous-use or high-drain applications.[7]This is still a fraction of the output of an alkaline cell, however.

Alkaline batteries[13]offer up to eight times the battery life of zinc–carbon batteries,[14]especially in continuous-use or high-drain applications.[7]

Storage[edit]

Manufacturers recommend storage of zinc–carbon batteries at room temperature; storage at higher temperatures reduces the expectedservice life.[1]Zinc–carbon batteries may be frozen without damage; manufacturers recommend that they be returned to normal room temperature before use, and thatcondensationon the battery jacket must be avoided. By the end of the 20th century, the storage life of zinc–carbon cells had improved fourfold over expected life in 1910.[7]

Durability[edit]

Zinc–carbon cells have a shortshelf life,as the zinc is attacked by ammonium chloride. The zinc container becomes thinner as the cell is used, because zinc metal is oxidized to zinc ions. When the zinc case thins enough, zinc chloride begins to leak out of the battery. The old dry cell is not leak-proof and becomes very sticky as the paste leaks through the holes in the zinc case. The zinc casing in the dry cell gets thinner even when the cell is not being used, because the ammonium chloride inside the battery reacts with the zinc. An "inside-out" form with a carbon cup and zinc vanes on the interior, while more leak-resistant, has not been manufactured since the 1960s.[7]

This picture shows the zinc container of fresh batteries at (a), and discharged batteries at (b) and (c). The battery shown at (c) had apolyethyleneprotection film (mostly removed in the photo) to keep thezinc oxideinside the casing.

Environmental impact[edit]

Disposal varies by jurisdiction. For example, in the U.S., thestate of Californiaconsiders all batteries as hazardous waste when discarded, and has banned the disposal of batteries with otherdomestic waste.[15]In Europe, battery disposal is controlled by theWEEE DirectiveandBattery Directiveregulations, and as such zinc–carbon batteries must not be thrown out with domestic waste. In the EU, most stores that sell batteries are required by law to accept old batteries forrecycling.

See also[edit]

References[edit]

- ^ab"Eveready Carbon Zinc Battery Handbook and Application Manual"(PDF).Energizer.2018.Retrieved2022-02-25.

- ^"Carbon Zinc - Batteries - Electrical".The Home Depot.Retrieved2022-02-25.

- ^"What is the difference between Alkaline and Carbon Zinc batteries?".KodakBatteries.com.Retrieved2022-02-25.

- ^"Carbon Zinc Aa Batteries".Walmart.Retrieved2022-02-25.

- ^abcd"Batteries | Boundless Chemistry".courses.lumenlearning.com.Retrieved2022-01-20.

- ^"Dry cell battery".

- ^abcdefgLinden, David; Reddy, Thomas B. (2002). "8".Handbook of batteries.McGraw-Hill.ISBN978-0-07-135978-8.

- ^"Monthly Battery Sales Statistics".Baj.or.jp.MoETI. May 2020.Retrieved2020-08-07.

- ^INOBAT 2008 statistics.ArchivedMarch 25, 2012, at theWayback Machine.

- ^Battery Waste Management– 2006 DEFRA.

- ^EPBA Sustainability Report,2010.

- ^"How do batteries work? A simple introduction".24 April 2006. Archived fromthe originalon 2020-06-09.

- ^"Put a charge into your battery savings".Chicago Tribune.2015-04-29.Retrieved2015-06-19.

- ^"Zinc Chloride Batteries".Radio Shack.Archivedfrom the original on 2015-02-12.Retrieved2015-06-19.

- ^"Batteries".Waste Prevention Information Exchange.California Department of Resources Recycling and Recovery (CalRecycle).Retrieved5 September2012.