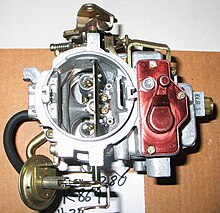

Carburetor

Acarburetor(also spelledcarburettororcarburetter)[1][2][3]is a device used by a gasolineinternal combustion engineto control and mix air and fuel entering the engine.[4]The primary method of adding fuel to the intake air is through theVenturi tubein the main metering circuit, though various other components are also used to provide extra fuel or air in specific circumstances.

Since the 1990s, carburetors have been largely replaced byfuel injectionfor cars and trucks, but carburetors are still used by somesmall engines(e.g. lawnmowers, generators, and concrete mixers) and motorcycles. In addition, they are still widely used on piston engine driven aircraft.Diesel engineshave always used fuel injection instead of carburetors, as the compression-based combustion of diesel requires the greater precision and pressure of fuel-injection.[5]

Etymology

[edit]The name "carburetor" is derived from the verbcarburet,which means "to combine with carbon",[6]or, in particular, "to enrich a gas by combining it withcarbonorhydrocarbons".[7]Thus a carburetor mixesintakeair with hydrocarbon-based fuel, such aspetrolorAutoGas(LPG).[8]

The name is spelled "carburetor" inAmerican Englishand "carburettor" inBritish English.[1][2][3]Colloquial abbreviations includecarbin the UK and North America orCarbyin Australia.[9]

Operating principle

[edit]This sectionneeds additional citations forverification.(October 2022) |

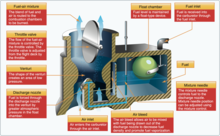

Air from the atmosphere enters the carburetor (usually via anair cleaner), has fuel added within the carburetor, passes into theinlet manifold,then through theinlet valve(s),and finally into thecombustion chamber.Most engines use a single carburetor shared between all of the cylinders, though some high-performance engines historically had multiple carburetors.

The carburetor works onBernoulli's principle:thestatic pressureof the intake air reduces at higher speeds, drawing more fuel into the airstream. In most cases (except for theaccelerator pump), the driver pressing thethrottle pedaldoes not directly increase the fuel entering the engine. Instead, the airflow through the carburetor increases, which in turn increases the amount of fuel drawn into the intake mixture.

The main disadvantage of basing a carburetor's operation on Bernoulli's Principle is that being a fluid dynamic device, the pressure reduction in aventuritends to be proportional to the square of the intake airspeed. The fuel jets are much smaller and fuel flow is limited mainly by the fuel's viscosity so that the fuel flow tends to be proportional to the pressure difference. So jets sized for full power tend to starve the engine at lower speed and part throttle. Most commonly this has been corrected by using multiple jets. InSUand other (e.g.Zenith-Stromberg) variable jet carburetors, it was corrected by varying the jet size.

The orientation of the carburetor is a key design consideration. Older engines usedupdraftcarburetors, where the air enters from below the carburetor and exits through the top. From the late 1930s,downdraftcarburetors become more commonly used (especially in the United States), along withside draftcarburetors (especially in Europe).

Fuel circuits

[edit]

Main metering circuit

[edit]The main metering circuit consists of a pipe which reduces to a narrows before widening again, forming aventuri(aka "barrel" ). Fuel is introduced into the air stream through small tubes (themain jets) at the narrowest part of the venturi, where the air is at its highest speed.[10]

Downstream of the venturi is athrottle(usually in the form of abutterfly valve) which is used to control the amount of air entering the carburetor. In a car, this throttle is connected to the vehicle's throttle pedal, which varies engine speed.

At lesser throttle openings, the air speed through the venturi is insufficient to maintain the fuel flow, therefore the fuel is instead supplied by the carburetor'sidleandoff-idle circuits.

At greater throttle openings, the speed of air passing through the venturi increases, which lowers the pressure of the air and draws more fuel into the airstream.[11]At the same time, the reduced manifold vacuum results in less fuel flow through the idle and off-idle circuits.

Choke

[edit]During cold weather fuel vaporizes less readily and tends to condense on the walls of the intake manifold, starving the cylinders of fuel and makingcold startsdifficult. Additional fuel is required (for a given amount of air) to start and run the engine until it warms up, provided by achoke valve.

While the engine is warming up the choke valve is partially closed, restricting the flow of air at the entrance to the carburetor. This increases the vacuum in the main metering circuit, causing more fuel to be supplied to the engine via the main jets. Prior to the late 1950s the choke was manually operated by the driver, often using a lever or knob on thedashboard.Since then, automatic chokes became more commonplace. These either use a bimetallicthermostatto automatically regulate the choke based on the temperature of the engine's coolant liquid, an electrical resistance heater to do so, or air drawn through a tube connected to an engine exhaust source. A choke left closed after the engine has warmed up increases the engine's fuel consumption and exhaust gas emissions, and causes the engine to run rough and lack power due to an over-rich fuel mixture.

However, excessive fuel canfloodan engine and prevent it from starting. To remove the excess fuel, many carburetors with automatic chokes allow it to be held open (by manually, depressing the accelerator pedal to the floor and briefly holding it there while cranking the starter) to allow extra air into the engine until the excess fuel is cleared out.

Another method used by carburetors to improve the operation of a cold engine is afast idlecam,which is connected to the choke and prevents the throttle from closing fully while the choke is in operation. The resulting increase in idle speed provides a more stable idle for a cold engine (by better atomizing the cold fuel) and helps the engine warm up quicker.

Idle circuit

[edit]The system within a carburetor that meters fuel when the engine is running at low RPM. The idle circuit is generally activated by vacuum under the throttle plate, which causes a low-pressure area in the idle passage/port thus causing fuel to flow through the idle jet. The idle jet is set at some constant value by the carburetor manufacturer, thus flowing a specified amount of fuel.

Off-idle circuit

[edit]Many carburetors use an off-idle circuit, which includes an additional fuel jet which is briefly used as the throttle starts to open. This jet is located in a low-pressure area behind the throttle. The additional fuel it provides is used to compensate for the reduced vacuum that occurs when the throttle is opened, thus smoothing the transition from the idle circuit to the main metering circuit.

Power valve

[edit]In afour-stroke engineit is often desirable to provide extra fuel to the engine at high loads (to increase the power output and reduceengine knocking). A 'power valve', which is a spring-loaded valve in the carburetor that is held shut by engine vacuum, is often used to do so. As the airflow through the carburetor increases the reduced manifold vacuum pulls the power valve open, allowing more fuel into the main metering circuit.

In atwo-stroke engine,the carburetor power valve operates in the opposite manner: in most circumstances the valve allows extra fuel into the engine, then at a certain engineRPMit closes to reduce the fuel entering the engine. This is done in order to extend the engine's maximum RPM, since many two-stroke engines can temporarily achieve higher RPM with a leaner air-fuel ratio.

This is not to be confused with the unrelatedexhaust power valvearrangements used on two-stroke engines.

Metering rod / step-up rod

[edit]A metering rod or step-up rod system is sometimes used as an alternative to a power valve in a four-stroke engine in order to supply extra fuel at high loads. One end of the rods is tapered, which sits in the main metering jets and acts as a valve for fuel flow in the jets. At high engine loads, the rods are lifted away from the jets (either mechanically or using manifold vacuum), increasing the volume of fuel can flow through the jet. These systems have been used by theRochester Quadra jetand in the 1950sCartercarburetors.

Accelerator pump

[edit]While the main metering circuit can adequately supply fuel to the engine in steady-state conditions, the inertia of fuel (being higher than that of air) causes a temporary shortfall as the throttle is opened. Therefore, an accelerator pump is often used to briefly provide extra fuel as the throttle is opened.[12]When the driver presses the throttle pedal, a smallpistonordiaphragmpump injects extra fuel directly into the carburetor throat.[13]

The accelerator pump can also be used to "prime" an engine with extra fuel prior to attempting acold start.[citation needed]

Fuel supply

[edit]Float chamber

[edit]

In order to ensure an adequate supply at all times, carburetors include a reservoir of fuel, called a "float chamber" or "float bowl". Fuel is delivered to the float chamber by afuel pump.A floating inlet valve regulates the fuel entering the float chamber, assuring a constant level.

Unlike in a fuel injected engine, the fuel system in a carbureted engine is not pressurized. For engines where the intake air travelling through the carburetor is pressurized (such as where the carburetor is downstream of asupercharger) the entire carburetor must be contained in an airtight pressurized box to operate.[citation needed]However, this is not necessary where the carburetor is upstream of the supercharger.

Problems of fuel boiling andvapor lockcan occur in carbureted engines, especially in hotter climates. Since the float chamber is located close to the engine, heat from the engine (including for several hours after the engine is shut off) can cause the fuel to heat up to the point of vaporization. This causes air bubbles in the fuel (similar to the air bubbles that necessitatebrake bleeding), which prevents the flow of fuel and is known as 'vapor lock'.

To avoid pressurizing the float chamber, vent tubes allow air to enter and exit the float chamber. These tubes usually extend into the carburetor throat, placed to prevent fuel from sloshing out of them into the carburetor.

Diaphragm chamber

[edit]If an engine must be operated when the carburetor is not in an upright orientation (for example in a chainsaw or airplane), a float chamber and gravity activated float valve would not be suitable. Instead, a diaphragm chamber is typically used. This consists of a flexiblediaphragmon one side of the fuel chamber, connected to aneedle valvewhich regulates the fuel entering the chamber. As the flowrate of the air in the chamber (controlled by the throttling valve/butterfly valve) decreases, the diaphragm moves inward (downward), which closes the needle valve to admit less fuel. As the flowrate of the air in the chamber increases, the diaphragm moves outward (upward) which opens the needle valve to admit more fuel, allowing the engine to generate more power. A balanced state is reached which creates a steady fuel reservoir level, that remains constant in any orientation.

Other components

[edit]

Other components that have been used on carburetors include:

- Air bleeds allowing air into various portions of the fuel passages, to enhance fuel delivery and vaporization.

- Fuel flow restrictorsin aircraft engines, to prevent fuel starvation during inverted flight.

- Heatedvaporizersto assist with the atomization of the fuel, particularly for engines usingkerosene,tractor vaporizing oilor inpetrol-paraffin engines[14]

- Early fuel evaporators

- Feedback carburetors, which adjusted the fuel/air mixture in response to signals from anoxygen sensor,in order to allow acatalytic converterto be used

- Constant vacuum carburetors (also called variable choke carburetors), whereby the throttle cable is connected directly to the throttle cable plate. Pulling the cord caused raw gasoline to enter the carburetor, creating a large emission of hydrocarbons.[15]

- Constant velocity carburetors use a variable throttle closure in the intake air stream before the accelerator pedal operated the throttle plate. This variable closure is controlled by intake manifold pressure/vacuum. This pressure-controlled throttle provides relatively even intake pressure throughout the engine's speed and load ranges.

Two-barrel and four-barrel designs

[edit]

The basic design for a carburetor consists of a single venturi (main metering circuit), though designs with two or four venturi (two-barrel and four-barrel carburetors respectively) are also quite commonplace. Typically the barrels consist of "primary" barrel(s) used for lower load situations and secondary barrel(s) activating when required to provide additional air/fuel at higher loads. The primary and secondary venturi are often sized differently and incorporate different features to suit the situations in which they are used.

Many four-barrel carburetors use two primary and two secondary barrels. A four-barrel design of two primary and two secondary barrels was commonly used inV8 enginesto conserve fuel at low engine speeds while still affording an adequate supply at high.

The use of multiple carburetors (e.g., a carburetor for each cylinder or pair of cylinders) also results in the intake air being drawn through multiple venturi.[16]Some high-performance engines have used multiple two-barrel or four-barrel carburetors, for example six two-barrel carburetors on Ferrari V12s.

History

[edit]In 1826, American engineerSamuel Moreyreceived a patent for a "gas or vapor engine", which ran onturpentinemixed with air.[17][18]The design did not reach production. In 1875 German engineerSiegfried Marcusproduced a car powered by the firstpetrolengine (which also debuted the firstmagneto ignitionsystem).[19][20][21]Karl Benz introduced his single-cylinderfour-strokepoweredBenz Patent-Motorwagenin 1885.[22][23]

All three of these engines used surface carburetors, which operated by moving air across the top of a vessel containing the fuel.[24]

The first float-fed carburetor design, which used anatomizer nozzle,was introduced by German engineers Wilhelm Maybach and Gottlieb Daimler in their 1885Grandfather Clock engine.[25]TheButler Petrol Cyclecar—built in England in 1888—also used a float-fed carburetor.[26][27]

The first carburetor for astationary enginewas patented in 1893 by Hungarian engineersJános CsonkaandDonát Bánki.[28][29][30]

The first four-barrel carburetors were theCarter CarburetorWCFB and the identicalRochester4GC, introduced in various General Motors models for 1952. Oldsmobile referred the new carburetor as the "Quadri-Jet" (original spelling)[31]while Buick called it the "Airpower".[32]

In the United States, carburetors were the common method of fuel delivery for most US-made gasoline (petrol) engines until the late 1980s, when fuel injection became the preferred method.[33]One of the last motorsport users of carburetors was NASCAR, which switched to electronic fuel injection after the2011 Sprint Cup series.[34]

In Europe, carburetors were largely replaced by fuel injection in the late 1980s, although fuel injection had been increasingly used in luxury cars and sports cars since the 1970s.EEClegislation required all vehicles sold and produced in member countries to have a catalytic converter after December 1992. This legislation had been in the pipeline for some time, with many cars becoming available with catalytic converters or fuel injection from around 1990.

Icing in aircraft engine carburetors

[edit]

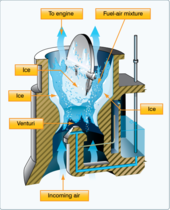

A significant concern for aircraft engines is the formation of ice inside the carburetor. The temperature of air within the carburetor can be reduced by up to 40 °C (72 °F),[35]due to a combination of the reduced air pressure in the venturi and thelatent heatof the evaporating fuel. The conditions during the descent to landing are particularly conducive to icing, since the engine is run at idle for a prolonged period with the throttle closed. Icing can also occur in cruise conditions at altitude.

A carburetor heat system is often used to prevent icing.[35]This system consists of a secondary air intake which passes around the exhaust, in order to heat the air before it enters the carburetor. Typically, the system is operated by the pilot manually switching the intake air to travel via the heated intake path as required. The carburetor heat system reduces the power output (due to the lower density of heated air) and causes the intake air filter to be bypassed, therefore the system is only used when there is a risk of icing.[35]

If the engine is operating at idle RPM, another method to prevent icing is to periodically open the throttle, which increases the air temperature within the carburetor.[35]

Carburetor icing also occurs on other applications and various methods have been employed to solve this problem. On inline engines the intake and exhaust manifolds are on the same side of the head. Heat from the exhaust is used to warm the intake manifold and in turn the carburetor. On V configurations, exhaust gases were directed from one head through the intake cross over to the other head. One method for regulating the exhaust flow on the cross over for intake warming was a weighted eccentric butterfly valve called a heat riser that remained closed at idle and opened at higher exhaust flow. Some vehicles used a heat stove around the exhaust manifold. It was connected to the air filter intake via tubing and supplied warmed air to the air filter. A vacuum controlled butterfly valve pre heat tube on the intake horn of the air cleaner would open allowing cooler air when engine load increased.

See also

[edit]- Bernoulli's principle

- Fuel injection

- Humidifier

- List of auto parts

- List of carburetor manufacturers

- Venturi effect

References

[edit]- ^ab"Definition of CARBURETTOR".merriam-webster.Merriam-Webster.Retrieved23 January2023.

- ^ab"carburettor noun - Definition, pictures, pronunciation and usage notes".oxfordlearnersdictionaries.Oxford University Press.Retrieved23 January2023.

- ^ab "carburetor".dictionary.cambridge.org.Cambridge University Press.Retrieved23 January2023.

- ^"What Is a Carburetor?".stateofspeed.2018-11-05.Retrieved2022-02-03.

- ^Torchinsky, Jason (4 August 2021)."This Is Why A Diesel Engine Can't Use A Carburetor".Jalopnik.Retrieved13 January2024.

- ^"carburetor".etymonline.Retrieved22 October2022.

- ^Woodford, Chris(23 October 2009)."How does a carburetor work?".Explain that Stuff.Retrieved22 October2022.

- ^"Carburetors Explained".autoevolution.1 August 2014.Retrieved22 October2022.

- ^Beale, Paul; Partridge, Eric (2003),Shorter Slang Dictionary,Routledge, p. 60,ISBN9781134879519

- ^Lind, Wallace Ludwig (1920).Internal-combustion engines; their principles and applications to automobile, aircraft, and marine purposes.Boston, Ginn. p. 71.Retrieved19 November2022.

- ^"Carburetor Basics - Tech Article - Chevy High Performance Magazine".MotorTrend.1 June 2002.Retrieved28 October2022.

- ^Packer, Ed (July 1953)."Know Your Carburetor- what it is, what it does".Popular Mechanics.Hearst Magazines: 183.Retrieved19 November2022.

- ^Hillier, V.A.W.; Pittuck, F.W. (1966). "Section 3.6".Fundamentals of Motor Vehicle Technology(Second ed.). Hutchinson Educational.ISBN9780091107116.

- ^Hutton, Frederick Remsen (1908).The gas-engine. A treatise on the internal-combustion engine using gas, gasoline, kerosene, alcohol, or other hydrocarbon as source of energy.New York, Wiley. p. 197.Retrieved19 November2022.

- ^Stermer, Bill (2002).Harley-Davidson Motorcycles.MotorBooks International. p. 154.ISBN978-1-61060-951-7.

- ^Hibbard, Jeff (1983).Baja Bugs & Buggies.HP Books. p. 24.ISBN0-89586-186-0.

- ^"Samuel Morey".The Linda Hall Library.Retrieved22 October2022.

- ^"A Detailed History Of The Internal Combustion Engine".HotCars.22 April 2021.Retrieved22 October2022.

- ^"Siegfried Marcus Car".asme.org.Retrieved22 October2022.

- ^"Siegfried Marcus Car".inventionandtech.Retrieved22 October2022.

- ^"HHF Factpaper: Siegfried Marcus – An Uncredited Inventive Genius".hebrewhistory.info.Retrieved22 October2022.

- ^"Carbueetoe".Google.Retrieved8 October2017.

- ^Inventors and Inventions.Marshall Cavendish. 2008. p. 91.ISBN978-0-7614-7761-7.Retrieved19 January2014.

- ^Webster's Revised Unabridged Dictionary,1913

- ^Eckermann, Erik (2001).World History of the Automobile.Society of Automotive Engineers. p. 276.ISBN978-0-7680-0800-5.

- ^"Csonka János Emlékmúzeum – The pulverized (spray carburetor)".csonkamuzeum.hu.2011.Retrieved2 November2020.

- ^Carlisle, Rodney (2005),Scientific American Inventions and Discoveries: All the Milestones in Ingenuity—From the Discovery of Fire to the Invention of the Microwave Oven,John Wiley & Sons, p. 335,ISBN978-0-471-66024-8,retrievedJuly 27,2014

- ^Rigden, John S.; Stuewer, Roger H. (2009).The Physical Tourist: A Science Guide for the Traveler.Springer.ISBN978-3-7643-8933-8.

- ^"Donát Bánki".Scitech.mtesz.hu.Archived fromthe originalon 17 July 2012.Retrieved19 January2014.

- ^"Inspirator and Pulverizer".

- ^"1952 Oldsmobile prestige brochure"(PDF).wildaboutcarsonline.Archived fromthe original(PDF)on 2016-03-04.Retrieved2016-05-09.

- ^"1952 Buick Airpower folder".Oldcarbrochures.Retrieved2016-05-09.

- ^Eckermann, Erik (2001).World History of the Automobile.Society of Automotive Engineers. pp. 199–200.ISBN978-0-7680-0800-5.Retrieved2016-05-09.

- ^Aumann, Mark (11 January 2012)."NASCAR takes 'really big step' with fuel injection".Nascar.Archived fromthe originalon 25 October 2012.Retrieved19 January2014.

- ^abcdPilots' Handbook of Aeronautical Knowledge(PDF).US Federal Aviation Administration. pp. 7–9–7–10.Retrieved11 April2022.