E-6 process

TheE-6 process(often abbreviated toE-6) is achromogenicphotographic processfor developingEktachrome,Fujichromeand othercolor reversal(also called slide or transparency)photographic film.

Unlike some color reversal processes (such asKodachromeK-14) that produce positive transparencies, E-6 processing can be performed by individual users with the same equipment that is used for processing black and white negative film orC-41color negative film. The process is highly sensitive to temperature variations: a heated water bath is mandatory to stabilize the temperature at 100.0 °F (37.8 °C) for the first developer and first wash to maintain process tolerances.

History[edit]

The E-6 process supersededKodak'sE-3andE-4processes. The E-3 process required fogging with light to accomplish image reversal and produced transparencies that faded quickly. The E-4 process used polluting chemicals, such as the highly toxic reversal agentborane tert-butylamine(TBAB).[1]

Non-Kodak color reversal films introduced in the 1980s were compatible with the E-6 process, including variants ofFujichromeandAgfachrome,sold byFujifilmandAgfa-Gevaert,respectively; one notable exception was Fujichrome 1600 Professional D, which was compatible with E-6 but used a customized PZ process for best results.[2]The PZ process was similar to E-6, but used a different fog-suppressing chemical.[3]

Process variations[edit]

There are two versions of the E-6 process. Commercial laboratories use a six-bath chemical process. The 'hobby' type chemistry kits, such as those produced byTetenal,use three chemical baths that combine the color developer and fogging bath solutions, and the pre-bleach, bleach and fixer bath solutions.[4]

Six-bath process version[edit]

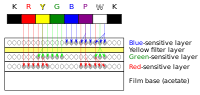

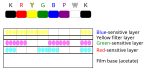

The structure of E-6 film has three separate light-sensitive layers; each layer is sensitive to a different group of wavelengths corresponding to red, green, and blue colors. When the film is exposed, each layer records a latent image based on its sensitivity. A yellow filter prevents blue light from exposing the green- and red-sensitive layers, which have some sensitivity to blue light.[5]

Kodak Publication Z-119 provides instructions for various methods to carry out the E-6 process,[6]including the use of continuous processors,[7]roller-transport processors,[8]rack-and-tank processors,[9]batch processing,[10]and rotary-tube processors;[11]however, they largely share the same steps and recommendations for time and temperature with the exception of rotary-tube processors. The first developer, first wash, and reversal bath must be carried out in darkness.[7][10]

| Step | Time[7][10](min.) | Temp.[7][10] | Schematic | Description | ||

|---|---|---|---|---|---|---|

| 1 | First developer bath | 6 | 98–103 °F (36.7–39.4 °C) |

|

This uses a potassium hydroquinonemonosulfonate–phenidoneblack & white film developer, with the preferred form of phenidone being 4-hydroxymethyl-4-methyl-1-phenyl-3-pyrazolidinone (13047-13-7). The first developer forms a negative silver image in each layer of the film. The first developer is time and temperature sensitive because it controls contrast.[6] | |

| 2 | First wash | 2 | 92–103 °F (33.3–39.4 °C) | This step once used an acetic acid stop bath, but was replaced with a water-only bath for process economy, with concomitant slight reduction of first developer strength.[6] | ||

| 3 | Reversal bath | 2 | 75–103 °F (23.9–39.4 °C) |

|

This bath prepares the film for the color developer step. A chemical reversal agent is absorbed into the emulsion, which is instantly effective. The reversal step can also be carried out using 800footcandle-seconds (8.6klx·s) oflight — this variation is used by process engineers to troubleshoot reversal bath chemistry problems such as contamination and issues of low tank turnover as process volumes decline.[6] | |

| 4 | Color developer bath | 6 | 98–103 °F (36.7–39.4 °C) |

|

This step is carried out to completion. The developer containsCD-3developing agent, and acts upon the chemically exposed silver halide that was not developed in the first developer to form a positive silver image. The metallic negative silver image formed in the first developer has no part in the reaction of this step. As the color development progresses, a metallic positive silver image is formed and the color developing agent is oxidized. Oxidized color developer molecules react with the color couplers and color dyes are formed in each of the three layers of the film.[6]Each layer of the film contains different color couplers, which react with the same oxidized developer molecules but form different color dyes. Variation in color developer pH causes color shifts on the green-magenta axis with Kodak E100G & E100GX andFujichromefilms and on the yellow-blue axis with older Ektachrome films.[12] | |

| 5 | Pre-bleach bath | 2 | 75–103 °F (23.9–39.4 °C) |

|

This bath was previously called "conditioner", but was renamed pre-bleach in the mid-1990s to reflect the removal of formaldehyde from the process used in the final rinse. In this solution,formaldehydeacts as a dye preservative andEDTAis used to "kick off" the bleach. The pre-bleach bath relies on carry-over of the color developer to function properly, therefore there is no wash step between the color developer and pre-bleach baths.[6] | |

| 6 | Bleach bath | 6 | 92–103 °F (33.3–39.4 °C) | This is a process-to-completion step, and relies on carry-over of pre-bleach to initiate the bleach. The bleach converts metallic silver intosilver bromide,which is converted to soluble silver compounds by the fixer. During bleaching, iron (III) EDTA is converted to iron (II) EDTA (Fe3+EDTA + Ag + Br−→ Fe2+EDTA + AgBr) before fi xing. Kodak also has a process variant which uses a higher concentration of bleach and a 4:00 bath time; but with process volumes declining, this variant has become uneconomical.[6] | ||

| 7 | Wash step | (optional) | Rinses off the bleach and extends the life of the fixer bath. This wash step is recommended for rotary tube, sink line and other low volume processing.[6] | |||

| 8 | Fixer bath | 4 | 92–103 °F (33.3–39.4 °C) |

|

This is a process-to-completion step.[6] | |

| 9 | Second fixer stage | (optional) | Using fresh fixer. The archival properties of film and paper are greatly improved using a second fi xing stage in a reverse cascade.[13]Many C-41RA (rapid access) minilab processors also use 2 stage reverse cascade fi xing for faster throughput. | |||

| 10 | Final wash | 4 | 92–103 °F (33.3–39.4 °C) | [6] | ||

| 11 | Final rinse | 1 | Ambient | Up until the mid-1990s, the final rinse was called a stabilizer bath, since it containedformaldehyde.Currently, the final rinse uses asurfactant,andmiconazole,an anti-fungal agent.[6] | ||

| 12 | Drying | var. | <145 °F (63 °C) | Drying in a dust-free environment.[6] | ||

-

An example of processed slide film showing a positive image

-

The E-6 process results in positive images that can be mounted and presented as slides

See also[edit]

References[edit]

- ^Bunting, Roger K. (1987).The Chemistry of Photography(2nd ed.). Normal, IL: Photoglass Press. p. 126.ISBN0-9616724-0-4.

- ^Schwalberg, Bob (May 1984)."Nine New Color Films".Popular Photography.p. 174.Retrieved6 September2023.

- ^Schwalberg, Bob (July 1984)."Battle of the Chrome Speed Champs".Popular Photography.pp. 56–59.Retrieved6 September2023.

- ^Rinses, washes, stop baths and stabilizer/final rinse (the final step of the process) are not counted in the counting of baths when describing both the conventional six bath and hobbyist three bath processes.

- ^"Process E-6 Using KODAK Chemicals, Process E-6 Publication Z-119 | Chapter 1: Processing solutions and their effects"(PDF).Kodak.Archived fromthe original(PDF)on August 25, 2005.

- ^abcdefghijklm"Process E-6 Using KODAK Chemicals, Process E-6 Publication Z-119".Kodak.Archived fromthe originalon October 8, 1999.Retrieved2007-07-04.

- ^abcd"Process E-6 Using KODAK Chemicals, Process E-6 Publication Z-119 | Chapter 6: Continuous Processors"(PDF).Kodak.Archived fromthe original(PDF)on October 15, 2008.

- ^"Process E-6 Using KODAK Chemicals, Process E-6 Publication Z-119 | Chapter 7: Roller-Transport Processors"(PDF).Kodak.Archived fromthe original(PDF)on August 30, 2008.

- ^"Process E-6 Using KODAK Chemicals, Process E-6 Publication Z-119 | Chapter 8: Rack-and-Tank Processors"(PDF).Kodak.Archived fromthe original(PDF)on September 5, 2008.

- ^abcd"Process E-6 Using KODAK Chemicals, Process E-6 Publication Z-119 | Chapter 9: Batch Processing"(PDF).Kodak.Archived fromthe original(PDF)on September 1, 2000.

- ^"Process E-6 Using KODAK Chemicals, Process E-6 Publication Z-119 | Chapter 10: Rotary-Tube Processors"(PDF).Kodak.Archived fromthe original(PDF)on February 5, 2005.

- ^"KODAK PROFESSIONAL EKTACHROME Films E100G and E100GX".Kodak.Retrieved2007-07-04.

- ^Schwartz, Dan (March 8, 2004)."Why two step fi xing is a Really Good Thing".Photo.net. Archived fromthe originalon June 24, 2007.Retrieved2007-07-04.Note this Photo.Net discussion thread reprints the technical paperPost Development Processingby Dr. Michael J. Gudzinowicz (1998).

External links[edit]

- Kodak Process E-6 Publication Z-119

- Kodak Q-LAB Process Control Handbook- more details than processing manual Z-119

- Kodak Professional First Developer Replenisher, Process E-6(PDF)

- FujiFilm USAProduct Bulletin Librarytechnical data sheets

- E-6 EktachromeDIY processing super-8 & 16mm.