Sulfonic acid

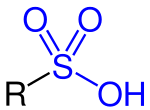

Inorganic chemistry,sulfonic acid(orsulphonic acid) refers to a member of the class oforganosulfur compoundswith the general formulaR−S(=O)2−OH,where R is an organicalkylorarylgroup and theS(=O)2(OH)group asulfonylhydroxide.[1]As a substituent, it is known as asulfo group.A sulfonic acid can be thought of assulfuric acidwith one hydroxyl group replaced by an organicsubstituent.Theparent compound(with the organic substituent replaced by hydrogen) is the parent sulfonic acid,HS(=O)2(OH),atautomerofsulfurous acid,S(=O)(OH)2.[a]Saltsorestersof sulfonic acids are calledsulfonates.

Preparation[edit]

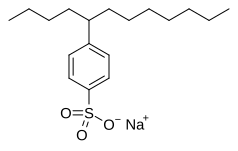

Aryl sulfonic acids are produced by the process ofsulfonation.Usually the sulfonating agent issulfur trioxide.A large scale application of this method is the production ofalkylbenzenesulfonic acids:

In this reaction, sulfur trioxide is anelectrophileand theareneis the nucleophile. The reaction is an example ofelectrophilic aromatic substitution.[1]

Alkylsulfonic acids can be prepared by many methods. Insulfoxidation,alkanes are irradiated with a mixture ofsulfur dioxideandoxygen.This reaction is employed industrially to produce alkyl sulfonic acids, which are used assurfactants.[2]

Direct reaction of alkanes with sulfur trioxide is not generally useful, except for the conversionmethanesulfonic acidtomethanedisulfonic acid.

Many alkane sulfonic acids can be obtained by the addition ofbisulfiteto terminal alkenes. Bisulfite can also bealkylatedbyalkyl halides:[2]

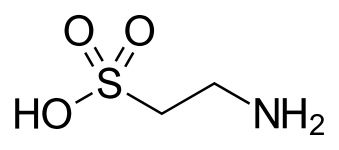

Sulfonic acids can be prepared by oxidation ofthiols:

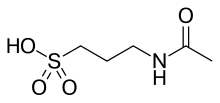

This pathway is the basis of the biosynthesis oftaurine.

Hydrolysis routes[edit]

Many sulfonic acids are prepared by hydrolysis ofsulfonyl halidesand related precursors. Thus,perfluorooctanesulfonic acidis prepared by hydrolysis of the sulfonyl fluoride, which in turn is generated by theelectrofluorinationof octanesulfonic acid. Similarly the sulfonyl chloride derived from polyethylene is hydrolyzed to the sulfonic acid. These sulfonyl chlorides are produced by free-radical reactions of chlorine, sulfur dioxide, and the hydrocarbons using theReed reaction.

Vinylsulfonic acidis derived by hydrolysis ofcarbyl sulfate,(C2H4(SO3)2), which in turn is obtained by the addition of sulfur trioxide toethylene.

Properties[edit]

Sulfonic acids are strong acids. They are commonly cited as being around a million times stronger than the correspondingcarboxylicacid. For example,p-Toluenesulfonic acidandmethanesulfonic acidhavepKavalues of −2.8 and −1.9, respectively, while those ofbenzoic acidandacetic acidare 4.20 and 4.76, respectively. However, as a consequence of their strong acidity, their pKavalues cannot be measured directly, and values commonly quoted should be regarded as indirect estimates with significant uncertainties. For instance, various sources have reported the pKaof methanesulfonic acid to be as high as −0.6[3]or as low as −6.5.[4]Sulfonic acids are known to react with solid sodium chloride (salt) to form the sodiumsulfonateand hydrogen chloride.[5]This property implies an acidity within two or three orders of magnitude of that of HCl(g),whose pKawas recently accurately determined (pKaaq= −5.9).[citation needed]

Because of their polarity, sulfonic acids tend to be crystalline solids or viscous, high-boiling liquids. They are also usually colourless and nonoxidizing,[6]which makes them suitable for use as acid catalysts in organic reactions. Their polarity, in conjunction with their high acidity, renders short-chain sulfonic acids water-soluble, while longer-chain ones exhibit detergent-like properties.

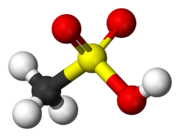

The structure of sulfonic acids is illustrated by the prototype,methanesulfonic acid.The sulfonic acid group, RSO2OH features a tetrahedral sulfur centre, meaning that sulfur is at the center of four atoms: three oxygens and one carbon. The overall geometry of the sulfur centre is reminiscent of the shape ofsulfuric acid.

- Representative sulfonic acids and sulfonates

-

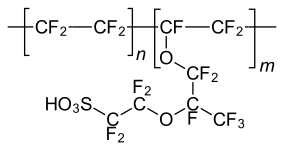

PFOS,a surfactant and a controversial pollutant.

-

p-Toluenesulfonic acid,a widely used reagent in organic synthesis.

-

Nafion,a polymeric sulfonic acid useful infuel cells.

Applications[edit]

Both alkyl and aryl sulfonic acids are known, most large-scale applications are associated with the aromatic derivatives.

Detergents and surfactants[edit]

Detergentsandsurfactantsare molecules that combine highly nonpolar and highly polar groups. Traditionally,soapsare the popular surfactants, being derived fromfatty acids.Since the mid-20th century, the usage of sulfonic acids has surpassed soap in advanced societies. For example, an estimated 2 billion kilograms ofalkylbenzenesulfonatesare produced annually for diverse purposes. Lignin sulfonates, produced by sulfonation ofligninare components ofdrilling fluidsand additives in certain kinds ofconcrete.[7]

Dyes[edit]

Many if not most of theanthraquinonedyes are produced or processed via sulfonation.[8]Sulfonic acids tend to bind tightly toproteinsandcarbohydrates.Most "washable"dyesare sulfonic acids (or have the functionalsulfonylgroup in them) for this reason.p-Cresidinesulfonic acidis used to make food dyes.

Acid catalysts[edit]

Being strong acids, sulfonic acids are also used ascatalysts.The simplest examples aremethanesulfonic acid,CH3SO2OH andp-toluenesulfonic acid,which are regularly used inorganic chemistryas acids that are lipophilic (soluble in organic solvents). Polymeric sulfonic acids are also useful.Dowexresin are sulfonic acid derivatives ofpolystyreneand is used as catalysts and for ion exchange (water softening).Nafion,a fluorinated polymeric sulfonic acid is a component of proton exchange membranes infuel cells.[9]

Drugs[edit]

Sulfa drugs,a class of antibacterials, are produced from sulfonic acids.

Lignosulfonates[edit]

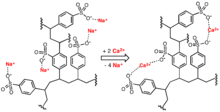

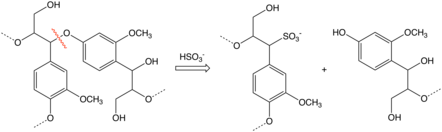

In thesulfite processfor paper-making, lignin is removed from the lignocellulose by treating wood chips with solutions of sulfite and bisulfite ions. These reagents cleave the bonds between the cellulose and lignin components and especially within the lignin itself. The lignin is converted tolignosulfonates,usefulionomers,which are soluble and can be separated from the cellulose fibers.

Reactions[edit]

Hydrolysis[edit]

Arylsulfonic acids are susceptible to hydrolysis, the reverse of the sulfonation reaction. Whereas benzenesulfonic acid hydrolyzes above 200 °C, most related derivatives are easier to hydrolyze. Thus, heating aryl sulfonic acids in aqueous acid produces the parent arene. This reaction is employed in several scenarios. In some cases the sulfonic acid serves as a water-solubilizing protecting group, as illustrated by the purification of para-xylene via its sulfonic acid derivative. In the synthesis of2,6-dichlorophenol,phenol is converted to its 4-sulfonic acid derivative, which then selectively chlorinates at the positions flanking the phenol. Hydrolysis releases the sulfonic acid group.[10]

Esterification[edit]

Sulfonic acids can be converted toesters.This class oforganic compoundshas the general formula R−SO2−OR. Sulfonic esters such asmethyl triflateare considered goodalkylating agentsinorganic synthesis.Such sulfonate esters are often prepared byalcoholysisof the sulfonyl chlorides:

- RSO2Cl + R′OH → RSO2OR′ + HCl

Halogenation[edit]

Sulfonyl halide groups occur when a sulfonyl functional group is singly bonded to a halogen atom. They have the general formula R−SO2−X where X is a halide, usually chloride or fluoride. Chlorides are produced by chlorination of sulfonic acids usingthionyl chloride.Sulfonyl fluorides can be produced by treating sulfonic acids withsulfur tetrafluoride:[11]

- SF4+ RSO3H → SOF2+ RSO2F + HF

Displacement by hydroxide[edit]

Although strong, the (aryl)C−SO3−bond can be broken by nucleophilic reagents. Of historic and continuing significance is the α-sulfonation of anthroquinone followed by displacement of the sulfonate group by other nucleophiles, which cannot be installed directly.[8]An early method for producingphenolinvolved the base hydrolysis of sodiumbenzenesulfonate,which can be generated readily from benzene.[12]

- C6H5SO3Na + NaOH → C6H5OH + Na2SO3

The conditions for this reaction are harsh, however, requiring 'fused alkali' or molten sodium hydroxide at 350 °C for benzenesulfonic acid itself.[13]Unlike the mechanism for the fused alkali hydrolysis of chlorobenzene, which proceeds through elimination-addition (benzynemechanism), benzenesulfonic acid undergoes the analogous conversion by an SNAr mechanism, as revealed by a14C labeling, despite the lack of stabilizing substituents.[14]Sulfonic acids with electron-withdrawing groups (e.g., with NO2or CN substituents) undergo this transformation much more readily.

Notes[edit]

- ^Neither the parent sulfonic acid nor the parent sulfurous acid have been isolated or even observed, although the monoanion of these hypothetical species exists in solution as an equilibrium mixture of tautomers:HS(=O)2(O−) ⇌ S(=O)(OH)(O−).

References[edit]

- ^abMarch, Jerry(1992),Advanced Organic Chemistry: Reactions, Mechanisms, and Structure(4th ed.), New York: Wiley,ISBN0-471-60180-2

- ^abKosswig, Kurt (2000). "Sulfonic Acids, Aliphatic".Ullmann's Encyclopedia of Industrial Chemistry.Weinheim: Wiley-VCH.doi:10.1002/14356007.a25_503.ISBN3-527-30673-0.

- ^Bordwell, Frederick G. (1988). "Equilibrium acidities in dimethyl sulfoxide solution".Accounts of Chemical Research.21(12): 456–463.doi:10.1021/ar00156a004.ISSN0001-4842.

- ^Smith, Michael; March, Jerry (2007).March's advanced organic chemistry: reactions, mechanisms, and structure(6th ed.). Hoboken, N.J.: Wiley-Interscience.ISBN978-1-61583-842-4.OCLC708034394.

- ^Clayden, Jonathan; Greeves, Nick; Warren, Stuart G. (January 2012).Organic chemistry(2nd ed.). Oxford.ISBN978-0-19-166621-6.OCLC867050415.

{{cite book}}:CS1 maint: location missing publisher (link) - ^Gernon, Michael D.; Wu, Min; Buszta, Thomas; Janney, Patrick (1999). "Environmental benefits of methanesulfonic acid".Green Chemistry.1(3): 127–140.doi:10.1039/A900157C.ISSN1463-9262.

- ^Kosswig, K. "Surfactants" in Ullmann's Encyclopedia of Industrial Chemistry 2002, Wiley-VCH, Weinheim.doi:10.1002/14356007.a25_747.

- ^abBien, Hans-Samuel; Stawitz, Josef; Wunderlich, Klaus (2002). "Anthraquinone Dyes and Intermediates".Ullmann's Encyclopedia of Industrial Chemistry.Weinheim: Wiley-VCH.doi:10.1002/14356007.a02_355.ISBN978-3527306732.

- ^Busca, Guido (2007). "Acid Catalysts in Industrial Hydrocarbon Chemistry".Chem. Rev.107(11): 5366–5410.doi:10.1021/cr068042e.PMID17973436.

- ^Otto Lindner; Lars Rodefeld (2005). "Benzenesulfonic Acids and Their Derivatives".Ullmann's Encyclopedia of Industrial Chemistry.Weinheim: Wiley-VCH.doi:10.1002/14356007.a03_507.ISBN978-3527306732.

- ^Boswell, G. A.; Ripka, W. C.; Scribner, R. M.; Tullock, C. W. (2011). "Fluorination by Sulfur Tetrafluoride".Organic Reactions.pp. 1–124.doi:10.1002/0471264180.or021.01.ISBN978-0-471-26418-7.

- ^Manfred Weber, Markus Weber, Michael Kleine-Boymann "Phenol" in Ullmann's Encyclopedia of Industrial Chemistry 2004, Wiley-VCH.doi:10.1002/14356007.a19_299.pub2.

- ^Bunnett, Joseph F.; Zahler, Roland E. (1951-10-01). "Aromatic Nucleophilic Substitution Reactions".Chemical Reviews.49(2): 273–412.doi:10.1021/cr60153a002.ISSN0009-2665.

- ^Oae, Shigeru; Furukawa, Naomichi; Kise, Masahiro; Kawanishi, Mitsuyoshi (1966)."The Mechanism of the Alkaline Fusion of Benzenesulfonic Acid".Bulletin of the Chemical Society of Japan.39(6): 1212–1216.doi:10.1246/bcsj.39.1212.